Specifications

Specification Value

Marley

/

Sigma Steel Cooling Tower

/

Specifications: Base

14

3.0 Construction:

3.1 The tower shall be capable of with-

standing water having a pH of 6.5 to

8.0; a chloride content (NaCl) up to 300

ppm; a sulfate content (SO

4

) up to

250 ppm; a calcium content (CaCO

3

)

up to 500 ppm; silica (SiO

2

) up to

150 ppm; and design hot water tem-

peraturesupto120°F.Thecirculating

water shall contain no oil, grease, fatty

acids, or organic solvents.

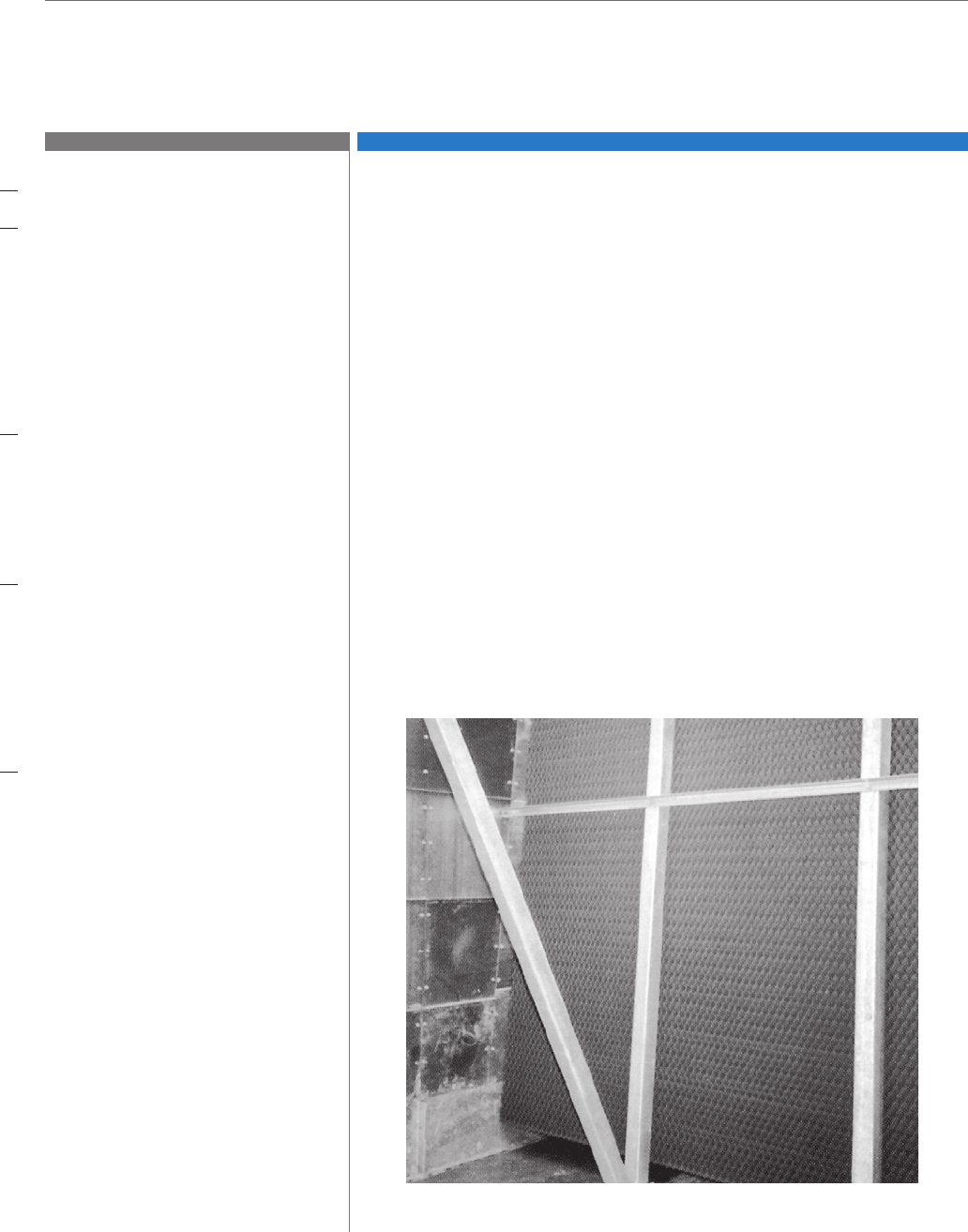

3.2 The structural framework of the tower,

as well as all basins and decking, shall

be of heavy gauge cold-formed steel

and/or mill shapes, hot-dip galvanized

after fabrication to a deposition of at

least 2.25 ounces of zinc per square

foot.

3.3 Column lines shall be on no greater

than 4' longitudinal centers, and the

base of all columns shall be firmly

anchored. Basic design criteria shall

be 30 psf wind load and 5%g seismic

load.Framingjointsshallbemade

with

1

⁄2" diameter and larger Series 300

stainless steel machine bolts, nuts and

washers.

3.4 Towers of more than one cell shall

include galvanized internal partitions

to separate the fan plenums, and a

hinged access door shall be provided

in each partition for freedom of access

throughout the tower.

■

The limiting water quality values indicated are those which are accept-

able for the normal materials of construction specified. If water of more

aggressive quality is anticipated, consider specifying a stainless steel

Sigma tower. See page 27.

■ Hot-dip galvanizing after fabrication assures that all steel surfaces will

be heavily coated with zinc. All shearing, bending, drilling, punching,

etc. will have been completed prior to galvanization.

■ Multicell towers must have plenum partitions between cells. Otherwise,

air will be induced downward through an inoperative fan, bypassing

the fill entirely. Without these partitions, part-load or off-season opera-

tion of the tower would be completely unsatisfactory.