Specifications

Specification Value

Marley

/

Sigma Steel Cooling Tower

/

Specifications: Base

15

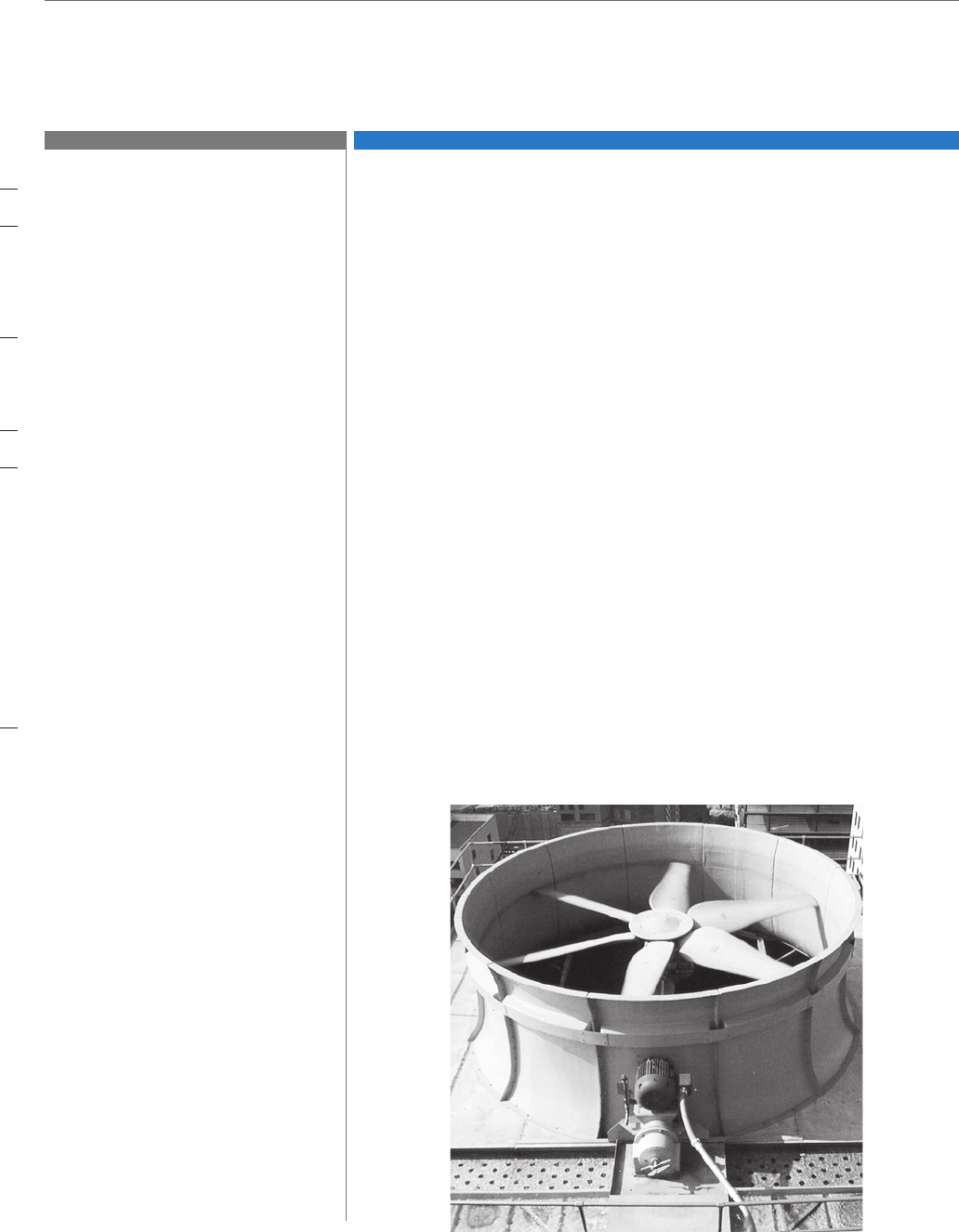

4.0 Fan Deck and Fan Cylinder:

4.1 The fan deck shall act as a working

platform for maintenance personnel. It

shall be fabricated of no less than 12

gauge steel, and shall be designed for

a uniform live load of 60 psf.

4.2 FancylindersshallbemoldedFRP.

They shall be through-bolted to the fan

deck structure to provide a consistent-

ly stable operating shroud for the fan.

5.0 Mechanical Equipment:

5.1 Fan(s)shallbepropeller-type,incorpo-

rating heavy duty blades of cast alumi-

num or high strength, inert composite

material. Blades shall be individually

adjustableandreplaceable.Fan(s)shall

be driven through a rightangle, indus-

trial-duty, oil-lubricated, geared speed

reducer. Speed reducers employing

pulleys and belts will not be accepted.

5.2 Motor(s) shall be ____ hp maximum,

TEFC,1.15servicefactor,andspecially

insulated for cooling tower duty. Speed

and electrical characteristics shall be

1800 (1800/900) RPM, single winding,

___ phase, ___ hertz, ___ volts.

■

The indicated design values for framing and decking not only give you

assurance that the tower can withstand long term operation in a hostile

environment — but that it will accept many years of inspection and

maintenance traffic by your operating personnel.

■ Fiberglass-reinforced polyester fan cylinders provide the close tip clear-

ances and smooth airflow contour necessary for good fan performance.

The inert, noncorroding nature of FRP assures that these characteristics

will persist. Their 6' to 7' height also provides protection for operating

personnel.

■ Propeller-type fans require only half the operating HP of blower-type

fans.

They should be readily adjustable to permit compensation for job site

conditions that may tend to overload the motor. The fans of one manu-

facturer require the purchase of special positioners for each increment

of fan blade pitch.

Standard fan drives of other manufacturers may use V-belts.

Considering the size of fans involved — and the horsepower applied —

this is not good design practice. Geareducer

®

drive is far more reliable

and trouble free, and is currently offered as an option by at least two

other cooling tower manufacturers.

■ Unless otherwise specified, motor speed will be 1800 RPM in 60 Hertz

areas and 1500 RPM in 50 Hertz areas. If you prefer the operating flex-

ibility of two-speed operation, please specify the RPM to be 1800/900

(1500/750 in 50 Hertz regions).