Marley

/

Sigma Steel Cooling Tower

/

Engineering Data : Inlet Piping

9

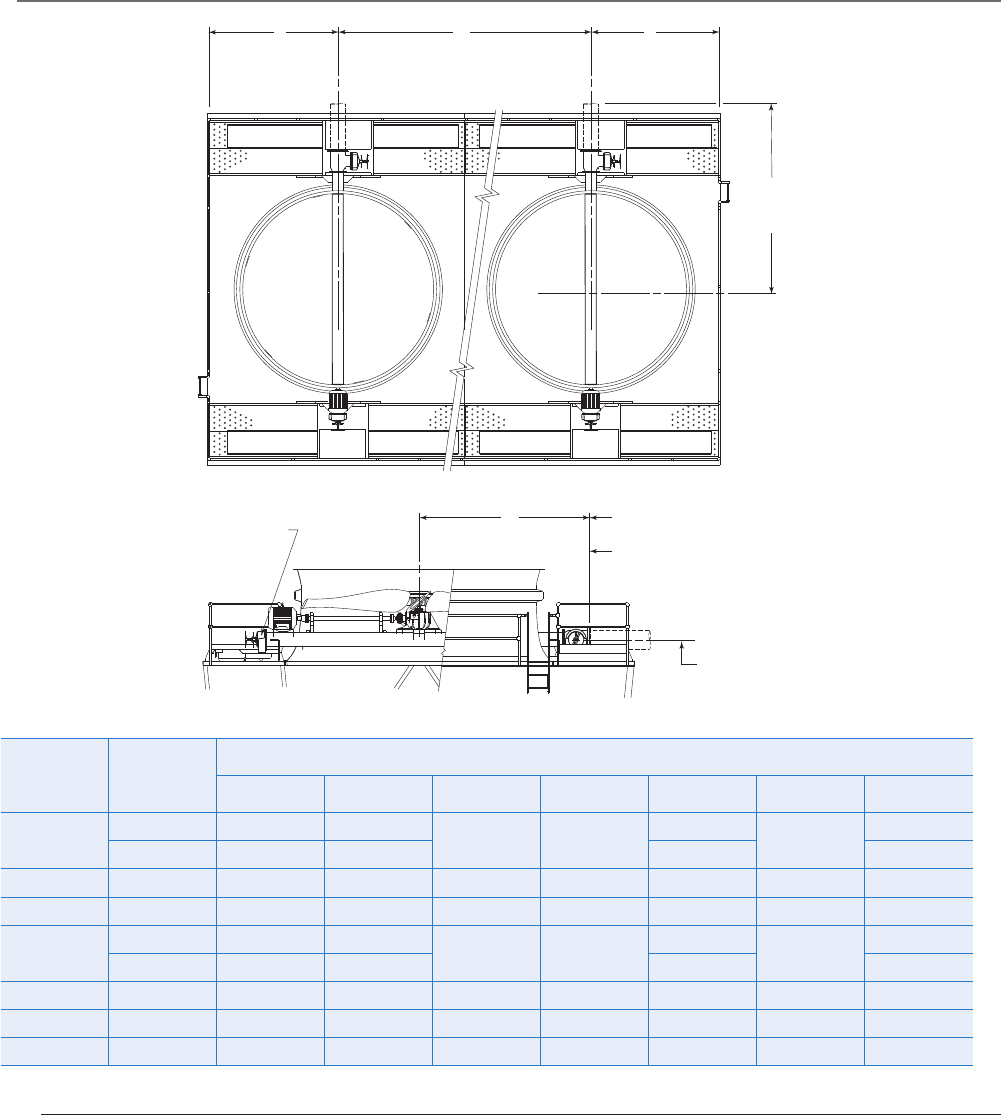

C C

COLUMN AND

ANCHOR BOLT

TYP. SINGLE CELL

D

TYP. MULTICELL

C

L

COLUMN AND

ANCHOR BOLT

C

L

FAN

C

L

INLET

C

L

INLET

C

L

FAN

C

L

F

MIN

REQUIRED CLEARANCE

C

L

E

G

C

OF FLANGE TO

BASE OF TOWER

COLUMNS (USE FOR

STATIC LIFT)

FAN

FACE OF

A DIA

INLET FLANGE

MARLEY PIPING

STOPS HERE

B DIA FLOW

CONTROL VALVE

C

L

L

C

L

TOWER

C

L

NOTE

1 Use this bulletin for preliminary layouts only. Obtain

current drawings from your Marley sales representative.

2 Pumping head contributed by the tower is static lift

“G”. Actual pumping head will vary according to tower

circulating GPM. Total pumping head will be furnished at

time of proposal.

3 If your application requires a bypass system,

recommended location is through tower endwall into

plenum area. Review of the system by SPX engineering is

required.

4 Marley piping terminates at face of a cast iron flat face

flange. Bolt circle conforms to class 125 lb. ANSI B 16.1

specifications.

5 Supports on tower for crossover piping are part of the

tower design. Do not support the riser’s dead load or

operating load from the tower. Do not brace the riser’s

seismic or thrust loads against the tower.

6 Butterfly valves or piping expansion joints (if used) are

by others and must be located outside the limits of the

cooling tower

“F”.

7 Motor must be located 180° from inlet.

Tower

Model

GPM

per cell

Dimensions

A B C D E F G

121-111

500-3800 10" 8"

6'-0" 12'0"

8'-10

1

⁄2"

13'-1

1

⁄4"

14'-6

3

⁄4"

3801-4500 12" 10" 9'-0

1

⁄2" 14'-7

3

⁄4"

122-111 650-6000 14" 10" 8'-0" 16'-0" 10'-0

1

⁄2" 14'-1

1

⁄4" 14'-7

3

⁄4"

123-111 650-6000 14" 10" 8'-0" 16'-0" 11'-0

1

⁄2" 15'-1

1

⁄4" 14'-7

3

⁄4"

124-111

1000-6000 14" 10"

10'-0" 20'-0"

11'-0

1

⁄2"

15'-1

1

⁄4"

14'-7

3

⁄4"

6001-7500 16" 12" 11'-1

1

⁄2" 14'-8

3

⁄4"

125-111 1000-7500 16" 12" 10'-0" 20'-0" 13'-1

1

⁄2" 17'-1

1

⁄4" 14'-8

3

⁄4"

126-111 1000-9000 16" 12" 12'-0" 24'-0" 13'-1

1

⁄2" 17'-1

1

⁄4" 14'-8

3

⁄4"

127-111 1500-10500 18" 14" 14'-0" 28'-0" 13'-5

5

⁄8" 17'-1

1

⁄4" 14'-9

3

⁄4"