20

Operating Procedures

Models 382/RC25

Disassembly

BE SURE THE CONTROL SWITCH IS IN

THE “OFF” POSITION.

Step 1

Remove the torque arm, handscrews, freezer door ,

beater assembly, scraper blades, torque rotor , and the

drive shaft, and take these parts to the sink for

cleaning.

Step 2

Remove the front drip tray and splash shield and take

them to the sink for cleaning.

Brush Cleaning

Step 1

Prepare a sink with a n approved cleaning s olution.

USE WARM WATER AND FOLLOW THE

MANUFACTURER’S SPECIFICATIONS. Make sure

all brushes provided with the freezer are available for

brush cleaning.

Step 2

Remove the:

S seals from the drive shaft.

S o-ring and front bearing from the freezer

door.

S door spout from the freezer door.

S draw valve and spring from the door spout.

S o-ring from the draw valve.

S o-ring and guide bearing from the torque

rotor.

S prime plug and prime plug o-ring.

Note: To remove o-rings, use a single service towel to

grasp the o-ring. Apply pressure in an upward direction

until the o-ring pops out of its groove. With the other

hand, push the top of the o-ring forward and it will roll

out of the groove and can be removed easily .

Step 3

Thoroughly brush clean all disassembled parts in the

cleaning solution making sure all lubricant and mix film

is removed. Place all the cleaned parts on a clean dry

surfacetoairdry.

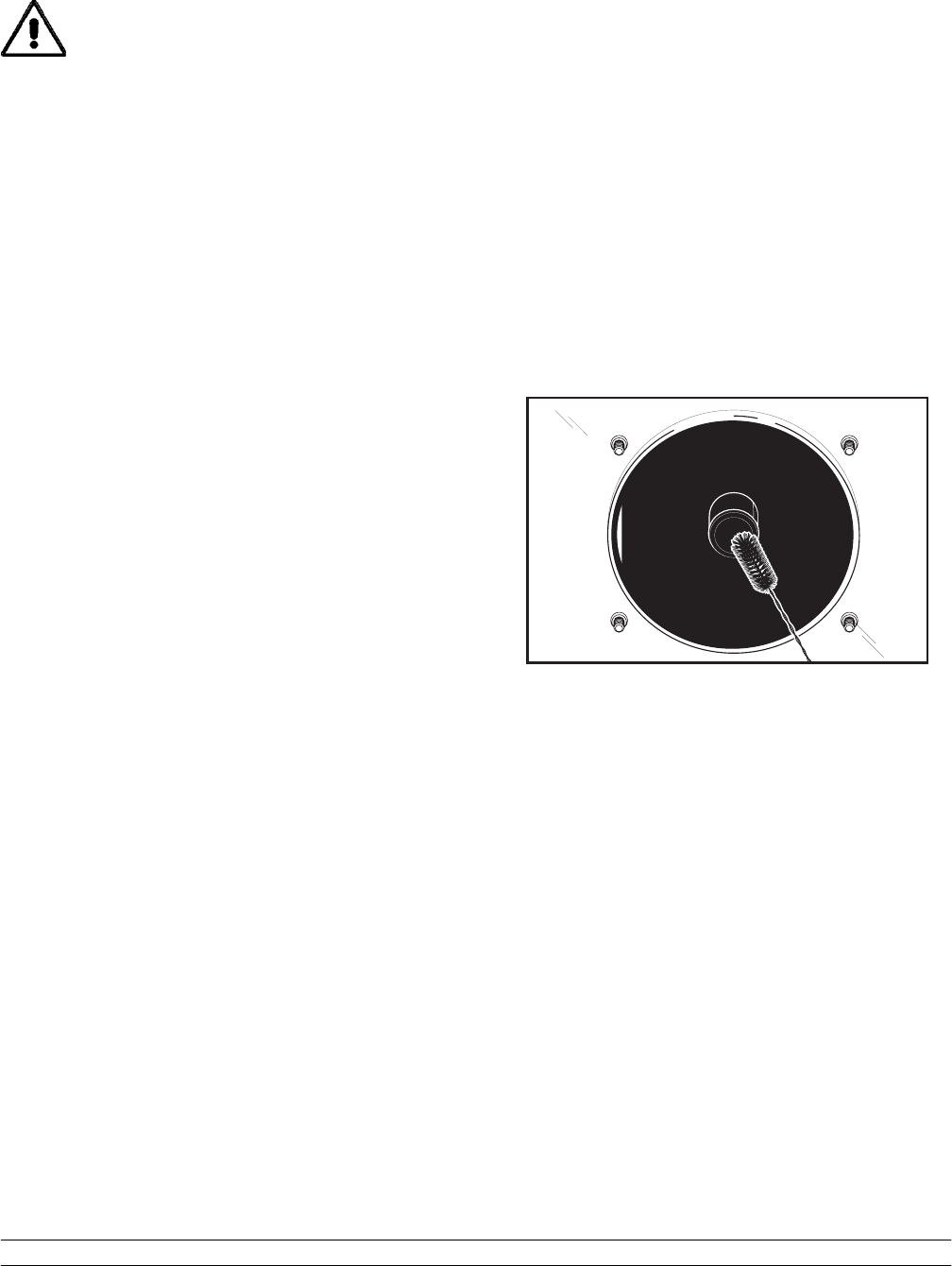

Step 4

Return to the freezer with a small amount of cleaning

solution. Brush clean the rear shell bearing with the

black bristle brush.

Figure 39

Step 5

Wipe clean all exterior surfaces o f the freezer.