3

Models 382/RC25 To the Installer

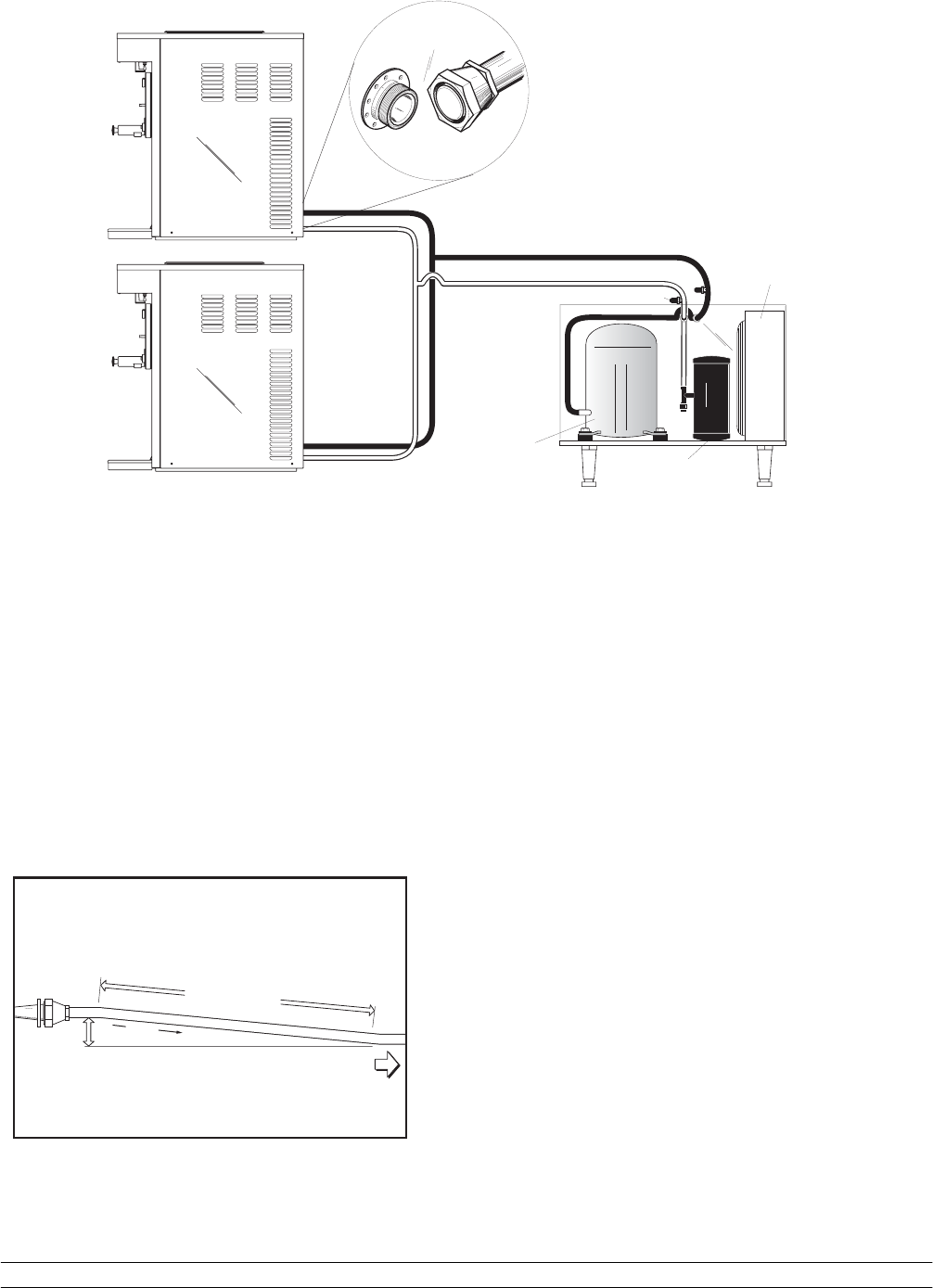

Note: 5/8” individual line lengths are not to exceed 75 ft. (22.8 m) maximum length each.

Total line length is not to exceed 150 ft. (45.7 m). 5/8” line + 5/8” line + 3/4” line = 150 ft. or less.

Figure 2

Compressor

Condenser

Liquid Refrigerant

Reciever

CONDENSING UNIT

Access Valve

DISPENSER UNIT

382

DISPENSER UNIT

382

Installation

Step 1

Install refrigeration lines from the dispenser to the

condensing unit. Do not create oil traps.

Note: For proper oil return, installation of horizontal

suction lines are to be sloped downward in the

direction of the condensing unit. The slope must be a

minimum 1/4” (6.4 mm) angle per 10 ft. (30.48 mm) of

line length.

FROM

DISPENSER

TO CONDENSER

¼" (.64 cm)

FLOW

10'-0"

(3.048 m)

Figure 3

Normally, any straight run of tubing must be supported

near each end of the run. Long runs require additional

supports. As a guide, 3/8” to 3/4” copper should be

supported every 5 ft. (1.5 m). When changing

directions, no corner should be left unsupported.

Supports should be placed a maximum of 2 ft. (.61 m)

in each direction from the corner . If soft copper tube is

used, make sure it is not kinked or flattened. If hard

drawn copper tubing is used, use only long radius

elbows.

Step 2

Braze the supplied quick connect/disconnect

couplings on the dispenser end of the r efrigeration

lines. Couplings are supplied with the dispenser.

Step 3

Braze the quick c onnect/disconnect couplings and

access tees on the condensing unit end of the

refrigeration lines. C ouplings and access tees ar e

supplied with the unit.

Note: Wrap a wet cloth around the brass coupling

bodies to prevent heat damage to the seal.

Step 4

Test the field constructed lines for leaks.