ENGLISH - 10

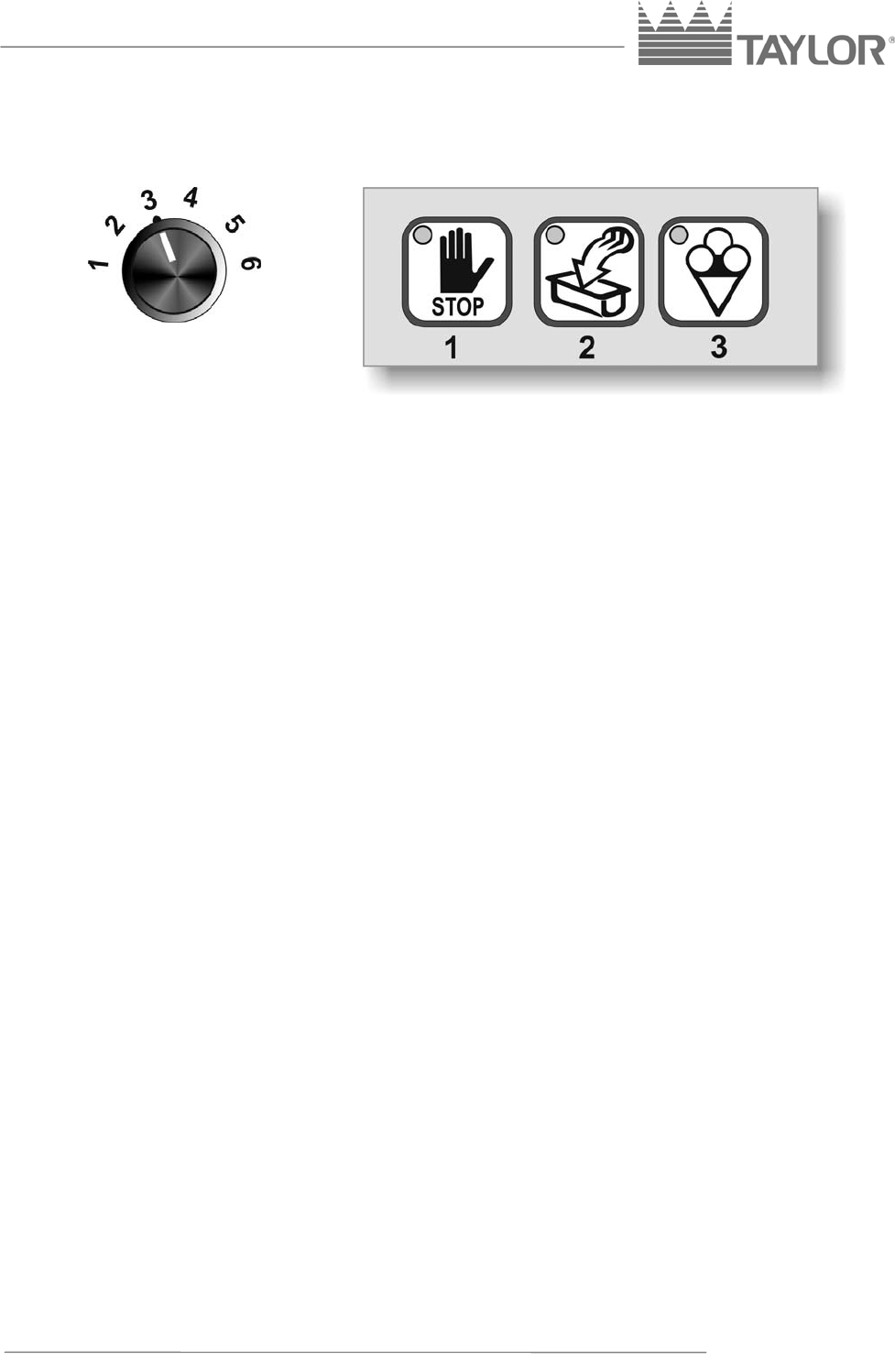

5.2 CONTROL PANEL C119

1. STOP

Whatever working cycle is in progress, it stops the machine and cancels any function in

progress.

2. DELIVERY

By pressing the DELIVERY pushbutton, only the agitator motor keeps on running. The

door safety catch is enabled and the agitator motor stops running after 15’ of operation,

the DELIVERY pushbutton warning light starts blinking.

3. PRODUCTION

When the machine is in STOP or DELIVERY position, press the PRODUCTION

pushbutton to start up the batch freezing cycle: the PRODUCTION warning light lights

up, the agitator motor starts up and after a few seconds, the compressor motor, the

motor fan and the electronic module for consistency control start up too. The electronic

module for consistency control allows reaching the ideal level of batch freezing,

independently of the kind of mixture used, on condition that it is within the minimum

and maximum quantities allowable for the machine capacity.

The following safety devices are all enabled: door safety catch, batch freezing safety

timer, control for lack of growth in consistency and the acoustic signal to signalize that

all functions have been stopped in case of overload.

On model C122, it is possible to decrease the consistency on “low consistency”,

pressing twice the PRODUCTION pushbutton, suitable for small product quantity.

CONSISTENCY SELECTOR (only C119)

The model C119 is provided with 6 different consistency values, which allow reaching

the best possible consistency according to the type and quantities of introduced

mixture. The max. consistency degree can be reached by selecting position 6.

However when a product shall be freezed, whose characteristics are unknown, it is

advisable to position the selector on the number corresponding to the quantity of litres

introduced into the cylinder decreased by 1.