ENGLISH - 16

7 TROUBLE-SHOOTING

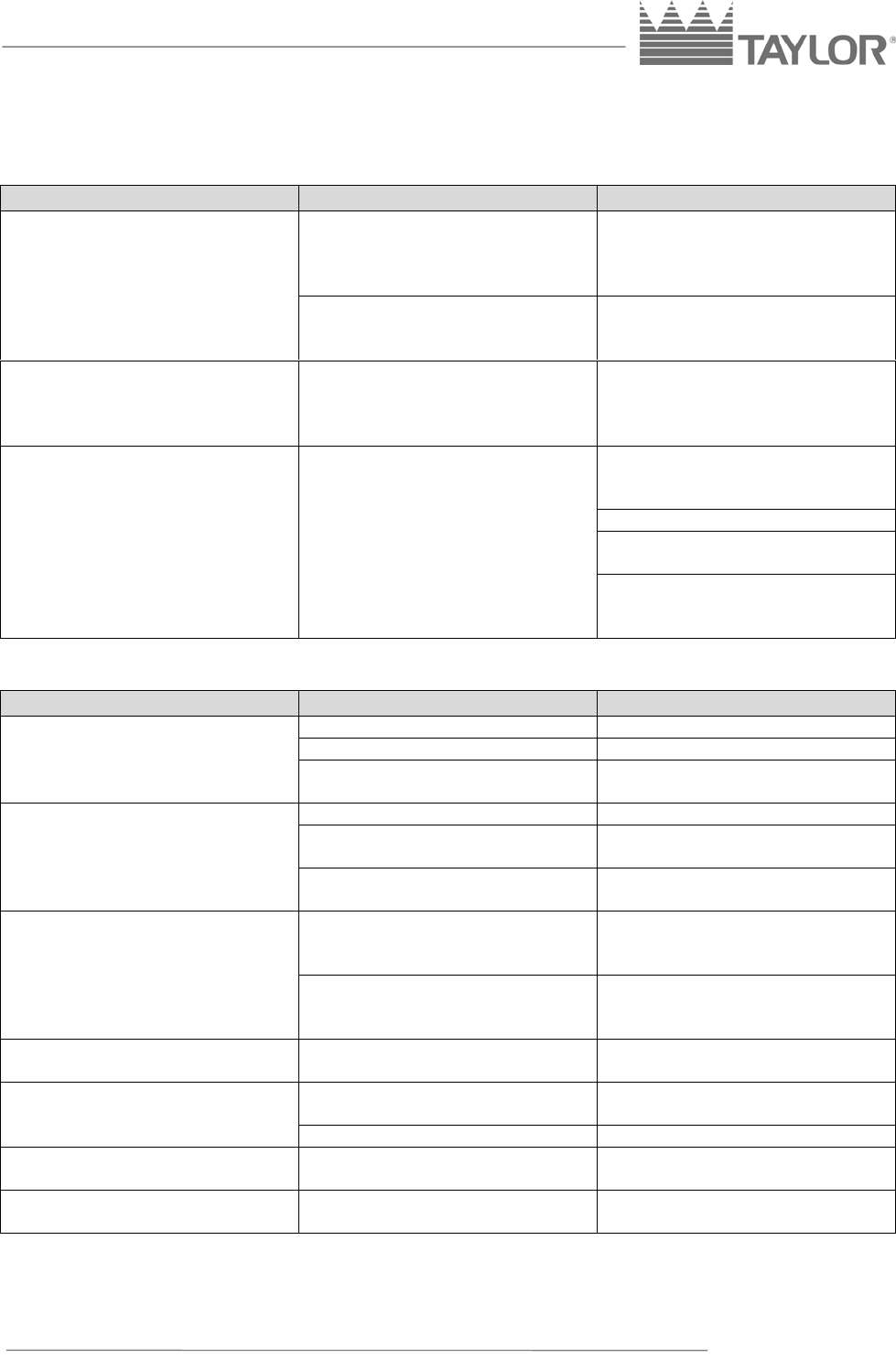

7.1 ALARM MANAGEMENT

MESSAGE DESCRIPTION REMEDIES

The agitator motor power

consumption is too high in

comparison to the current

transformer calibration.

Check whether the agitator is

blocked and the supply voltage

correct.

STOP pushbutton blinking and

agitator motor still.

The current transformer circuit is

cut off.

Check the circuit and in case of

necessity replace the current

transformer.

STOP pushbutton is fixed, the

DELIVERY pushbutton is blinking

and the agitator motor is still.

The agitator motor power

consumption is too high in

comparison to the thermal

protection value.

Check the motor from an electrical

point of view, the consistency

value calibration and check that

the agitator is not blocked.

Check that the quantity and the

quality of introduced mixture are

correct.

Check the cooling parameters.

Check whether the agitator

scraping pads are worn out.

STOP pushbutton is fixed, the

DELIVERY pushbutton is blinking,

an acoustic signal (beep) is

released and the agitator motor is

running.

Alarm for lack of growth in

consistency.

Check that the agitator direction of

rotation is correct (T4 three-

phase).

7.2 TROUBLE-SHOOTING

TROUBLE POSSIBLE CAUSES REMEDIES

Electric trouble Send for a technician

Incorrect power supply Check phases

The machine does not start (STOP

pushbutton ON without active

alarms)

The door or the hopper grid is

open.

Close the door and lower the

hopper grid.

Master switch OFF Close the switch

Blown fuse on the electronic card

Check and replace it (send for a

technician)

The machine does non start

(STOP pushbutton OFF)

Failure in electronic card or

pushbutton panel

Send for a technician

(C119 water) Lack of condensing

water

Check the presence of water in the

water system to which the machine

is connected. Check the cocks.

Since the first phases of the batch

freezing cycle, the compressor

works intermittent

Dirty air condenser or broken down

fan.

Clean the condenser by means of

a brush and check that the fan

motor correctly works.

Traces of liquid ice-cream in the

drip drawer

Worn-out agitator stuffing box Check and/or replace it.

Worn-out scraping pads

Check and in case of necessity

replace them

Batch freezing times are prolonged

and the ice-cream is still wet.

Trouble in the refrigerant circuit Send for a technician

During batch freezing the machine

is noisy and the agitator stops.

The belt slips

Check the belt tension and in case

of necessity replace it.

During the delivery of ice-cream,

the machine is noisy.

The product is too hard.

Make sure that you have pressed

the “DELIVERY”pushbutton.