Page 15

INPUT CHECK AND ADJUSTMENT

1. Make sure all gas appliances are off except the furnace.

2. Clock the gas meter with the furnace operating (determine the

dial rating of the meter) for one revolution.

3. Match the “Sec” column in the gas flow (in cfh) Table 3 with the

time clocked.

4. Read the “Flow” column opposite the number of seconds

clocked.

5. Use the following factors if necessary.

For 1 Cu. Ft. Dial Gas Flow CFH =

Chart Flow Reading / 2

For 1/2 Cu Ft. Dial Gas Flow CFH =

Chart Flow Reading / 4

For 5 Cu. Ft. Dial Gas Flow CFH =

10X Chart Flow Reading / 4

6. Multiply the final figure by the heating value of the gas obtained

from the utility company and compare to the nameplate rating.

This must not exceed the nameplate rating.

7. Changes can be made by adjusting the manifold pressure.

a. Attach a manifold pressure gauge.

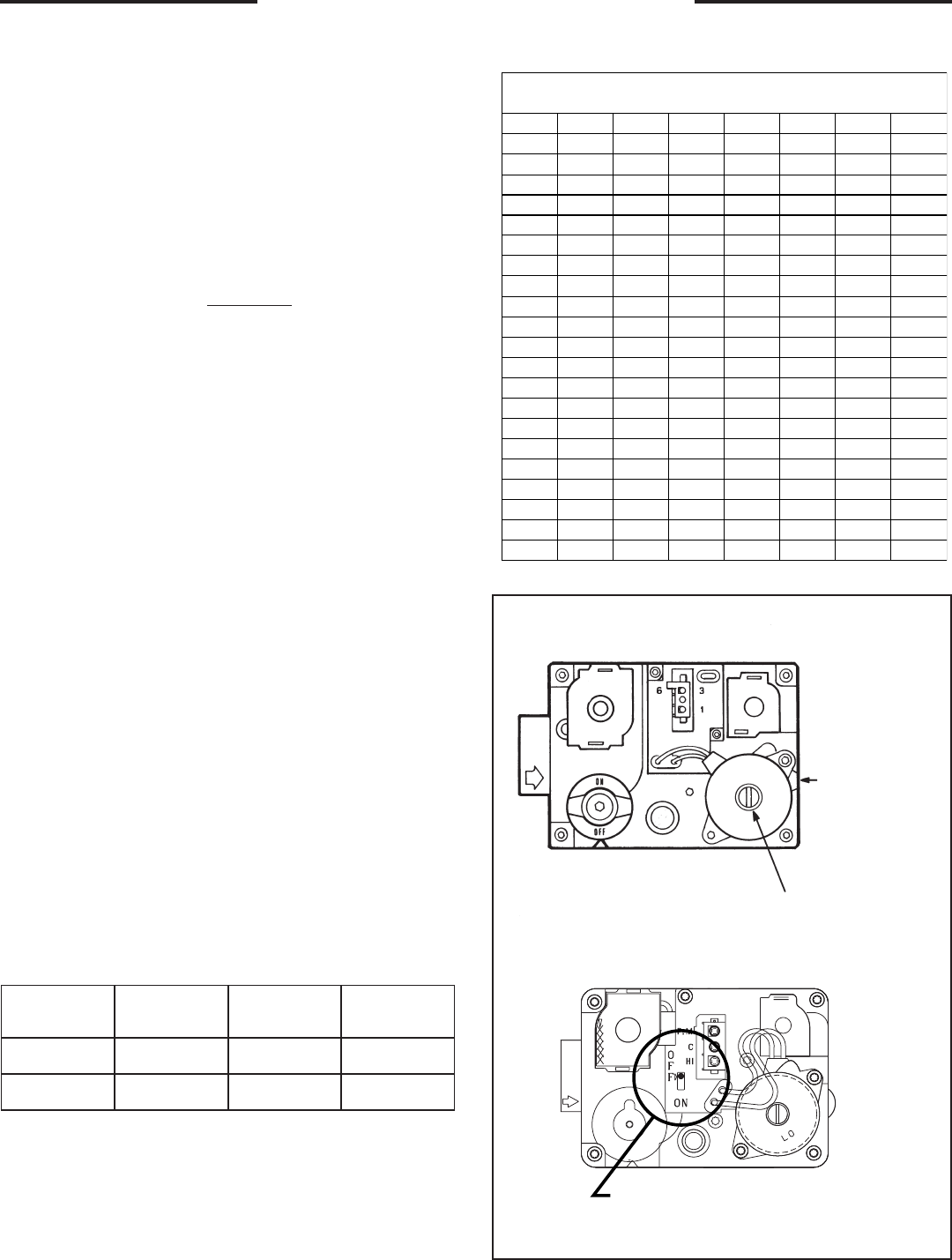

b. Remove the slot screw on top of the gas valve for 1st stage

manifold pressure adjustment. Remove slot screw on outlet

side for 2nd stage adjustment (See Figure 17).

c. Turn the adjustment nut in to increase the gas flow rate, and

out to decrease the gas flow rate using a 3/32" hex wrench.

Note:

If Model YCZ036F1,3M is installed in a region where NOX must be

below 40 nanograms per input to 72,000 BTUH.

GAS PIPING INSTALLATION

GAS FLOW IN CUBIC FEET PER HOUR

2 CUBIC FOOT DIAL

Sec. Flow Sec. Flow Sec. Flow Sec. Flow

8 900 29 248 50 144 82 88

9 800 30 240 51 141 84 86

10 720 31 232 52 138 86 84

11 655 32 225 53 136 88 82

12 600 33 218 54 133 90 80

13 555 34 212 55 131 92 78

14 514 35 206 56 129 94 76

15 480 36 200 57 126 96 75

16 450 37 195 58 124 98 73

17 424 38 189 59 122 100 72

18 400 39 185 60 120 104 69

19 379 40 180 62 116 108 67

20 360 41 176 64 112 112 64

21 343 42 172 66 109 116 62

22 327 43 167 68 106 120 60

23 313 44 164 70 103 124 58

24 300 45 160 72 100 128 56

25 288 46 157 74 97 132 54

26 277 47 153 76 95 136 53

27 267 48 150 78 92 140 51

28 257 49 147 80 90 144 50

TABLE 3

u

1st Stage (Lo)

Manifold

Pressure

Adjustment

2nd Stage (Hi)

Manifold

Pressure

Adjustment

HIGH ALTITUDE INSTALLATION

Unit nameplate ratings are based on equipment operation from sea

level to 2000 feet elevation above sea level. If the unit installation

is from 2000 - 4500 feet elevation, it will be necessary to change

the burner orifices to the noted sizes, (ref. National Fuel Gas Code,

sec 8.1.2, Appendix F, Table F4).

SAG

EPYT

SSERP.NAM

).C.W.ni(

EZISECIFIRO

tf0002-0

EZISECIFIRO

tf0054-0002

LARUTAN3.3

24

*

34

ENAPORP0.014555

* DEPPIHSYROTCAF

Switch Toggles

"ON" or "OFF"