Page 18

START - UP

PRE-START QUICK CHECKLIST

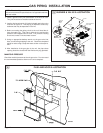

● Is the unit properly located and level with the proper clearance?

See Figure 4.

● Is the duct work correctly sized, run, taped, insulated, and

weatherproofed with proper unit arrangement? See Ductwork

Installation section.

● Is the gas piping correctly sized, run, trapped, and purged of air?

See Gas Piping section.

● Is the condensate line properly sized, run, trapped, and pitched?

● Is the filter of the correct size and number? Is it clean and in place?

● Is the wiring properly sized and run according to the unit wiring

diagram?

● Are all the wiring connections, including those in the unit, tight?

● Has the unit been properly grounded and fused with the recom-

mended fuse size? See Wiring Data.

● Is the thermostat level, correctly wired, well located, and set for

the proper heat anticipation?

● Have the air conditioning systems been checked at the service

ports for charge and leak tested if necessary?

● Does the condenser fan and indoor blower turn free without

rubbing, and are they tight on the shafts?

● Has the indoor blower speed been determined and the proper

speed been set? See the Unit Wiring Diagram.

● Has all work been done in accordance with applicable local and

national codes?

● Are all covers and access panels in place to prevent air loss and

safety hazards?

STARTING THE UNIT IN THE COOLING MODE

CAUTION: Before starting the system on the cooling cycle, turn the

thermostat switch to OFF and close the unit disconnect switch. This

procedure energizes the compressor crankcase heater, vaporizing

any liquid refrigerant in the crankcase. This is a precaution against

foaming at start-up which could damage the compressor bearings.

Allow the heater to operate a minimum of eight (8) hours.

NOTE: See the section on “Sequence of Operation” for a

description of the cooling operating sequence.

To start the unit in the cooling mode, set the thermostat system

switch to COOL and move the thermostat COOL indicator to a

setting below room temperature. The condenser (outdoor) fan

motor compressor and evaporator (indoor) fan motor will operate

automatically.

OPERATING PRESSURES

After the unit has operated in the cooling mode for a short period of

time, install pressure gauges on the gauge ports of the discharge

and suction line valves. Check the suction and discharge pressures

and compare them to the normal operating pressures provided in

the unit’s SERVICE FACTS.

NOTE: Do not use the pressures from the unit's SERVICE FACTS

to determine the unit refrigerant charge. The correct charge is

shown on the unit nameplate. To charge the system accurately,

weigh in the charge according to the unit nameplate.

VOLTAGE

With the compressor operating, check the line voltage at the unit.

The voltage should be within the range shown on the unit name-

plate. If low voltage is encountered, check the size and length of the

supply line from the main disconnect to the unit. The line may be

undersized for the length of the run.

COOLING SHUT DOWN

Place the system selector in the OFF position or reset thermostat at

a setting above room temperature.

Do not de-energize the main power disconnect except when unit is

to be serviced. Power is required to keep the heat pump compres-

sor warm and boil off refrigerant in the compressor.

HEATING CYCLE

NOTE: See Sequence of Heating Operation.

These units are equipped with a solid-state ignition control that

lights the burners each time the thermostat calls for heat. The

burners are extinguished during the OFF cycle.

The gas heating section of the unit can be started using the following

procedure:

1. Be sure the thermostat is at its lowest setting and the power to

the unit is off.

a. Turn the main shutoff valve on the gas supply line ON.

b. Turn or switch the manual valve on the combination gas

valve ON position.

2. Be sure the burner compartment access panel is in place.

a. Turn on the electrical power to the unit.

b. Turn the thermostat to the highest setting in the heating

cycle.

3. As the thermostat calls for heat, the system cycles as follows:

a. The combustion blower is energized.

b. The pressure switch is closed.

c. The gas valve opens and the ignitor lights the burner.

d. Cycle the thermostat on and off a few times to check out the

control system and burner operation characteristics.

4. With the burners operating, check the manifold pressure with a

manometer. Do not exceed recommended pressures.

5. Adjust the unit to obtain an air temperature rise with that

specified on the unit nameplate.

6. NOTE: For manifold pressures and orifice sizes for gas with

other BTU ratings, contact the local gas utility. Manifold

pressure should be 3.3 inches water column (+0.1). Input must

not exceed the value shown on the rating plate.

7. Set the heat anticipator of the thermostat to equal the amperage

draw of the gas valve, approximately 0.7.