Page 8

LOCATIONS AND RECOMMENDATIONS

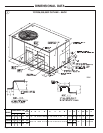

15. Access and service clearances for the unit must be given

careful consideration when locating the duct entrance open-

ings. Figure 4 provides unit dimensions.

16. All fabricated outdoor ducts should be as short as possible.

CLEARANCES

1. The recommended clearances for single-unit installations are

illustrated in Figure 4. These minimum requirements are not

only an important consideration when determining unit place-

ment, but they are also essential to ensure adequate service-

ability, maximum capacity, and peak operating efficiency.

2. Any reduction of the unit clearances indicated in these illustra-

tions may result in condenser coil starvation or the recirculation

of warm condenser air. Actual clearances which appear to be

inadequate should be reviewed with a local sales engineer.

IMPORTANT:

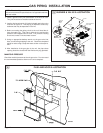

1. Remove the Flue and Air Inlet Hood with the gasket from the

return air section of the unit.

The screws that attach the flue and air inlet hood will be installed

in their proper location at the factory. Therefore, they must be

removed and then used to attach the flue and air inlet hood.

2. Remove the packaging material from the components and

secure the Flue and Air Inlet Hood with the gasket to the unit

with sheet metal screws as illustrated in Figure 16 on page 14.

NOTE: Outdoor air or other requirements during heating

operation that result in supply air temperatures below 80

degrees F or return air temperatures below 50 degrees F may

cause flue gas condensate to form and is to be avoided.

INSTALLATION

UNIT SUPPORT

If the unit is to be roof mounted, check the appropriate building

codes for weight distribution requirements. Refer to the applicable

roof curb mounting instruction. Check the unit’s nameplate for

supply voltage required. Determine if adequate electrical power is

available. The furnace may be installed on Class A, B, or C roofing

material.

LOCATION AND CLEARANCES

Installation of the unit should conform to local building codes or, in

the absence of local codes, to the National Fuel Gas Code,

ANSIZ223.1, Latest Revision, and the National Electrical Code.

Canadian installations must conform to CSA and local codes.

Select a location that will permit adequate combustion and ventila-

tion air in accordance with Section 5.3, Air For Combustion and

Ventilation, of the National Fuel Gas Code, ANSIZ223.1, Latest

Revision, or applicable provisions of the local building code.

PLACING AND RIGGING

1. Before preparing the unit for lifting, check the outline drawing for

center of gravity for lifting safety. Because of placement of

internal components, the unit’s weight may be unevenly distrib-

uted. Approximate unit weights are given in Figure 2, page 3.

NOTE: Accessory BAYLIFT002AA, a kit of four (4) lifting lugs, is

required for rigging the unit for hoisting. See Figure 7, insert B.

2. Insert the four lifting lugs in the openings provided in the drip lip

on the perimeter of the unit. See Figure 7, insert B. A tap or jerk

to the lug will overcome the interference that arises due to the

nipple on the lug.

3. Before hoisting the unit, be sure that the proper method of

rigging is used, with straps or slings and spreader bars for

protection during lifting. Always test-lift the unit to determine the

exact unit balance and stability before hoisting it to the installa-

tion location.

continued from page 7

Examine all flue product-carrying areas of the furnace, its vent

system, and the main burner for safe operation. A periodic

inspection of the furnace should be made at the start of each

heating season.

Replacement parts list for this Gas/Electric Air Conditioner may

be obtained by contacting your local manufacturer representa-

tive.

6. Location of the unit must allow for service clearance around it.

Clearance of the unit must be given careful consideration. See

Figure 4.

7. IMPORTANT: The air outlet duct must have one (1) inch

clearance to combustible material downstream from the

unit.

8. Exhaust vents or other sources of contaminated air should not

be near the unit’s air inlet, if outside air is to be introduced as

makeup air or a ventilation feature is to be used.

9. Check the handling facilities to ensure the safety of personnel

and the unit(s).

10. Caution must be taken at all times to avoid personal

injuries and/or damage to the equipment.

11. The unit must be mounted level for proper drainage of water

through the holes in the base pan.

12. The unit must not be exposed to direct roof water runoff.

13. Flexible duct connectors must be of a flame retardant material.

All duct work outside of the structure must be insulated and

weatherproofed in accordance with local codes.

14. Roof flashing must be installed to seal the roof curb cavity and

must conform to local building codes.