-12-

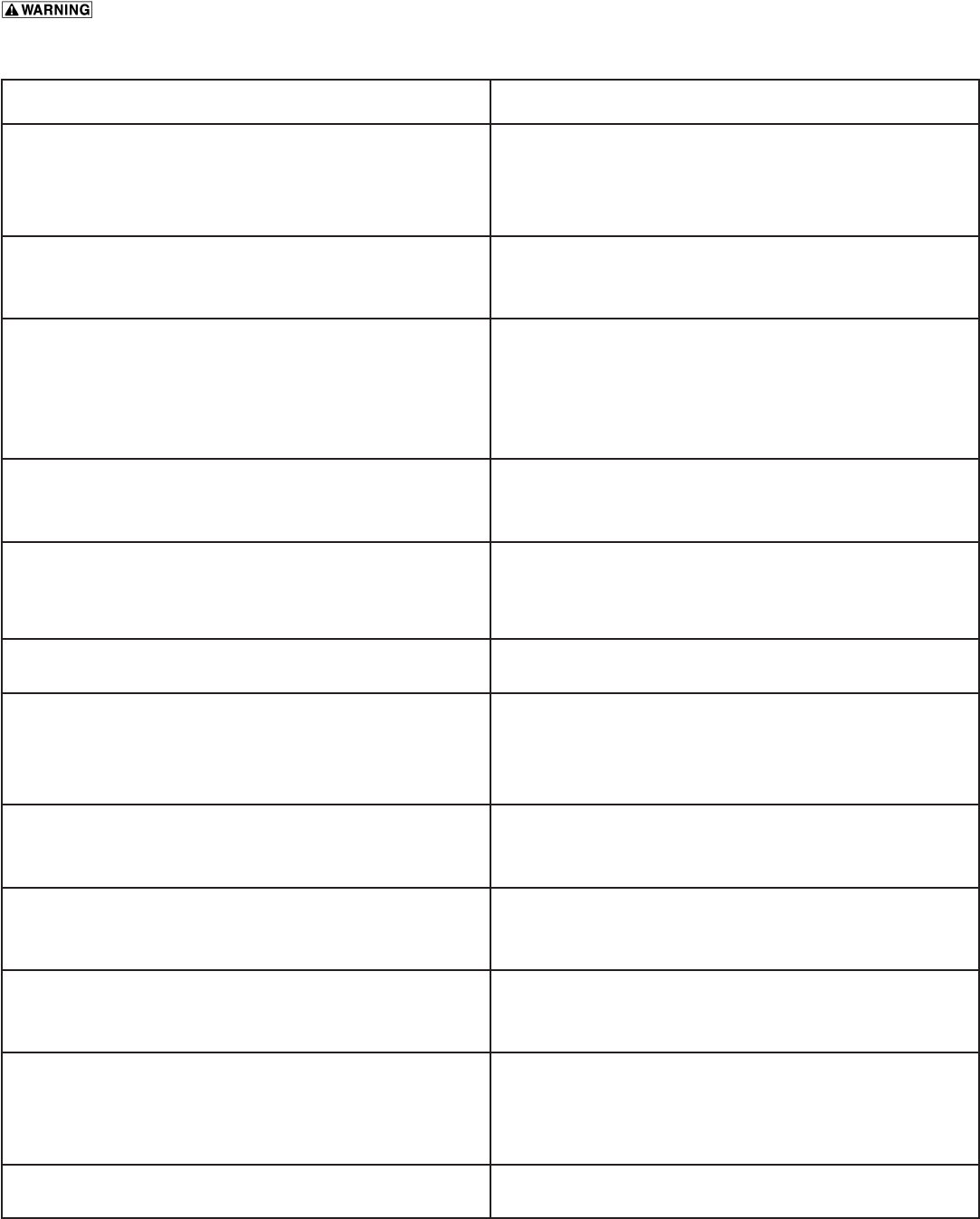

XII. TROUBLESHOOTING

PROBLEM POSSIBLE SOLUTION

Compressor will not run, compressor has no current draw. 1. Main circuit breaker open.

2. Compressor overload tripped.

3. Cabinet temperature satised.

4. Wired wrong or faulty connection.

5. INTELA-TRAUL

®

control malfunction.

6. Start component malfunction.

7. Compressor motor windings open.

Compressor will not run, current draw and trips overload. 1. Low voltage.

2. Start component malfunction.

3. Compressor windings shorted.

4. Locked rotor.

5. Excessive discharge pressure.

Compressor short cycles on overload. 1. Low voltage.

2. Low refrigerant charge.

3. Dirty condenser coil and/or lter.

4. Wired wrong or faulty connection.

5. Condenser fan inoperative.

6. Run capacitor malfunction.

7. Start component malfunction.

8. INTELA-TRAUL

®

control malfunction.

9. High head pressure.

Compressor short cycles. 1. Improper air ow over evaporator coil.

2. Low ambient conditions.

3. INTELA-TRAUL

®

control malfunction.

4. Bad sensors.

5. Temp differential set too close.

Continuous unit operation. 1. Loss of refrigerant.

2. Excessive drawer openings.

3. INTELA-TRAUL

®

control malfunction.

4. Broken compressor valves.

5. Very dirty condenser and/or lter.

6. Check the “DL,” if higher than 160F.

Compressor run time lengthy. 1. Partial loss of refrigerant.

2. High ambient conditions.

3. Dirty condenser coil or improper air ow over.

Condenser coil. 1. Excessive product load.

2. Excessive drawer openings.

3. Drawer gasket requires replacement.

4. INTELA-TRAUL

®

control malfunction.

5. Contaminates in refrigeration system.

6. Compressor valve leakage.

7. Inadequate defrost cycle.

Low suction pressure. 1. Capillary tube restricted.

2. Drier plugged.

3. Loss of refrigerant.

4. Poor air ow.

5. Iced evaporator coil.

High head pressure. 1. Improper air ow across condenser.

2. High ambient conditions.

3. Overcharge of refrigerant.

4. Air in system.

5. Dirty condenser coil.

Will not defrost or inadequate defrost. 1. Defrost heater malfunction.

2. Wired wrong or faulty connection.

3. Cabinet air leak.

4. Coil sensor failure.

5. INTELA-TRAUL

®

control malfunction

1

.

Coil icing. 1. Number of defrost cycles too few.

2. Defrost duration too short.

3. Cabinet air leak.

4. Drain tube plugged.

5. Defrost heater not working.

6. Non-frozen product put into cabinet.

7. Coil sensor failure.

The cabinet & coil sensors show high temperature. 1. Sensor needs replacing (place sensor tip and thermometer in ice

water. Change sensor ir readings differ, or if sensor displays

-40 02 266)

Certain procedures in this section require electrical and refrigeration system test or measurements

while power is applied to the machine, exercise extreme caution at all times. If test points are not easily accessible,

disconnect power, attach test equipment and reapply power to test.