III. i - PLACING EQUIPMENT ON TOP OF UNIT:

Equipment may be placed on top of your Traulsen full-

size undercounter or equipment stand. However,

please be aware that a stainless steel worktop is re-

quired on cabinets being used to support equipment

weighing in excess of 100 lbs. or producing heat in

excess of 140°F to the top surface. Optional stainless

steel tops are available from Traulsen.

IV. OPERATION

IV. a - REFRIGERATORS:

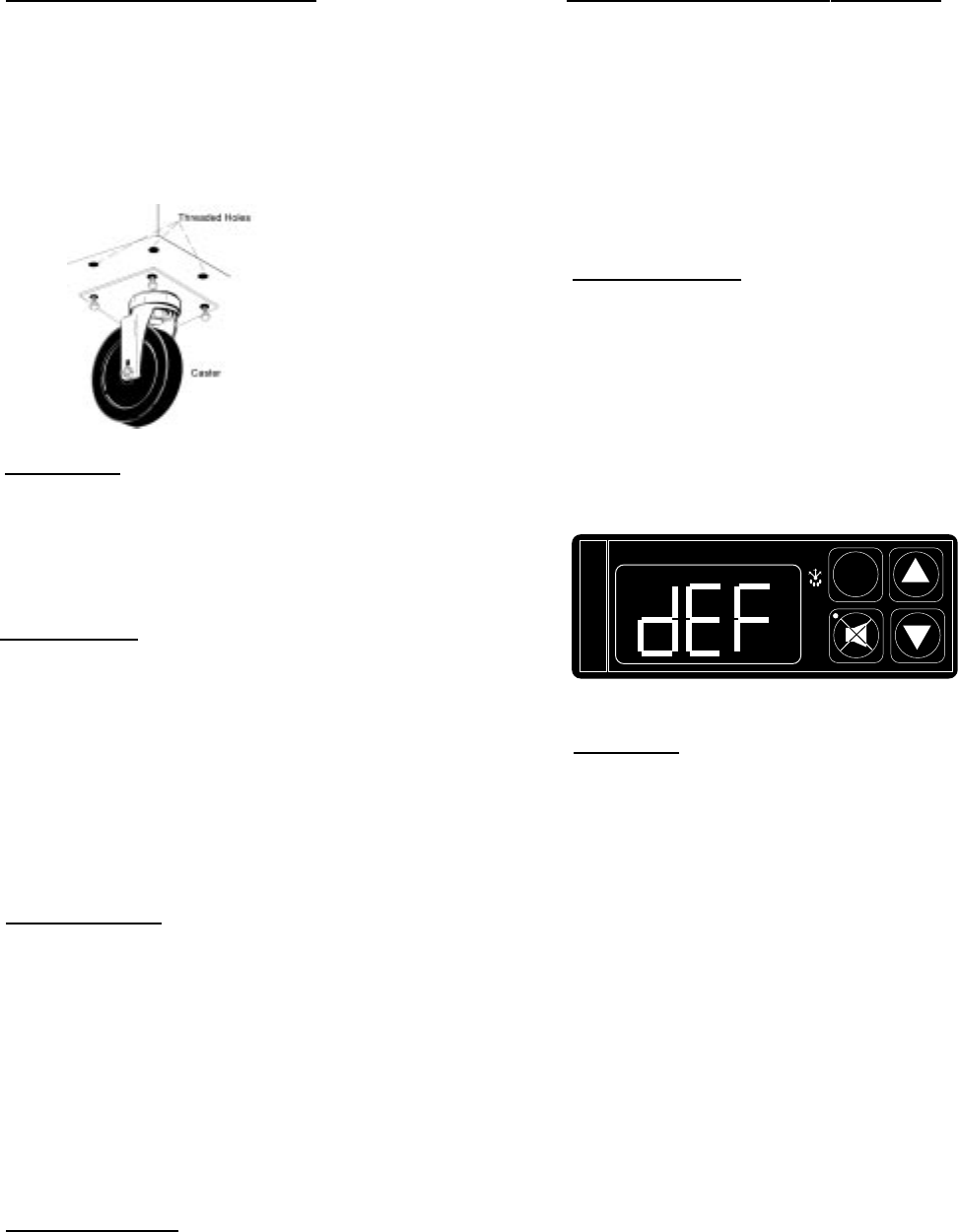

Both refrigerators and freezers do not require manual

defrosting. During normal operation, a refrigerator

continuously circulates above freezing cabinet air

through the coil. A compressor “OFF” cycle occurs

every hour to melt any frost which may accumulate

on the coil during the compressor “ON” cycle. The

control will read “dEF” when this occurs (see figure

4). With standard holding refrigerators, high relative

humidity is also maintained to prevent dehydration of

stored product.

IV. b - FREEZERS:

During normal operation, a freezer continuously cir-

culates below freezing cabinet air through the coil. The

coil requires a periodic defrosting for proper opera-

tion. This is accomplished by an automatic, time acti-

vated, temperature/time terminated, defrost program,

utilizing hot gas from the refrigeration system. The

controller is preset at the factory for six equally spaced

defrost cycles within each 24-hour period.

At the start of a freezer defrost cycle, both the com-

pressor and evaporator fans are OFF. The INTELA-

TRAUL control will read “dEF” (see figure 4). When a

temperature device affixed to the coil senses 70°F, the

coil is fully defrosted and the compressor operation

is resumed. The coil fans are delayed from starting at

the termination of a defrost cycle. Fan operation is

automatically resumed, they can also be started by a

time or temp delay (whichever comes first). In case of

temp delay, it uses the same coil sensor and starts at

32°F. The total refrigeration system operation is then

resumed.

During freezer defrost operation, heat is confined to

the coil enclosure to prevent any significant rise in

temperature within the food zone. The fan delay con

-3-

III. INSTALLATION (continued)

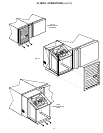

III. d - INSTALLING LEGS OR CASTERS (cont’d):

Please note that Traulsen units are not designed to be

moved while on legs. If the unit requires moving, a

pallet jack or forklift should be used to prevent dam-

age. For installing casters, the casters are “plate”

type, and require the use of four (4) bolts each to se-

cure them firmly to the cabinet bottom at each corner

(see figure 3). The caster bolts are tightened using a

1/2” socket wrench.

III. e - SHELF PINS:

The unit ships with shelves and shelf pins installed.

Check all shelf pins to assure they are tightened down

as they may have come loose during shipping. Ro-

tate the pins clockwise until they are secured against

the side of the cabinet.

III. f - CORD & PLUG:

Most self-contained models are supplied with a cord

& plug attached. It is shipped coiled at the rear of the

cabinet, secured by a nylon strip. For your safety and

protection, all units supplied with a cord and plug in-

clude a special three-prong grounding plug on the ser-

vice cord. Select only a dedicated electrical outlet with

grounding plug for power source. NOTE: Do not un-

der any circumstances, cut or remove the round

grounding prong from the plug, or use an extension

cord.

III. g - POWER SUPPLY:

The supply voltage should be checked prior to con-

nection to be certain that proper voltage for the cabi-

net wiring is available (refer to the serial tag to deter-

mine correct unit voltage). Make connections in ac-

cordance with local electrical codes. Use qualified

electricians.

Use of a separate, dedicated circuit is required. Size

wiring to handle indicated load and provide necessary

overcurrent protector in circuit (see amperage require-

ments on the unit’s serial tag).

III. h - WIRING DIAGRAM:

Refer to the wiring diagram for any service work per-

formed on the unit. Should you require one, please

contact Traulsen Service at (800) 825-8220, and pro-

vide the model and serial number of the unit involved.

Fig. 3

Fig. 4

FREEZER

SET

INTELA-TRAUL

°F °C