17

2

OPERATIONS TO BE PERFORMED WHEN SUBSTITUTING THE

INJECTORS

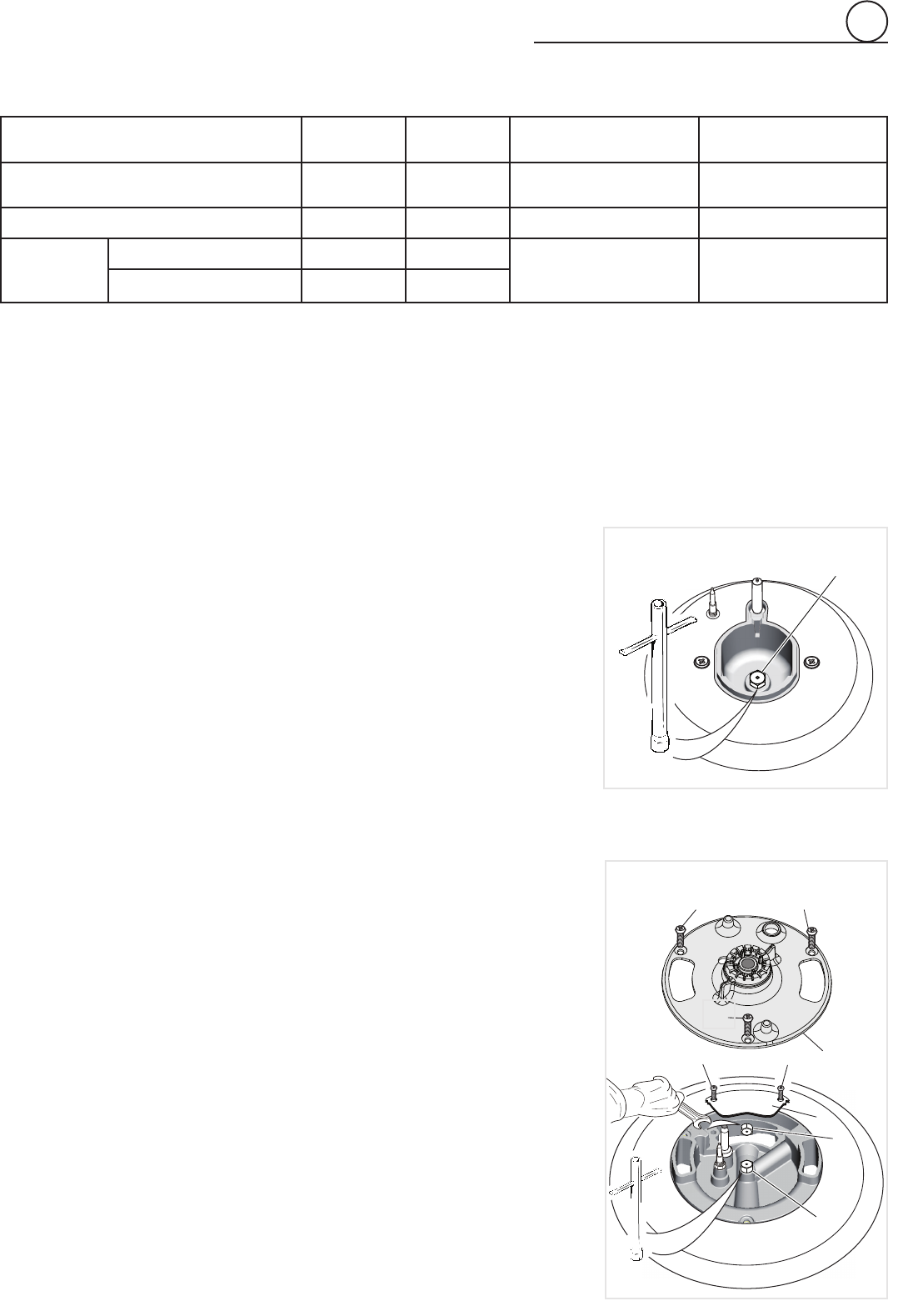

• Removethepansupports,theburnercapsandtheamespreaders.

• Dualburneronly(g.2.9):Unscrewtheno.3xingscrews“A”andremovetheinner

crownamespreader“B”;thenunscrewtheno.2xingscrews“C”andremovethe

coverplate“D”.

• Usingawrenchsubstitutethenozzleinjectors“J

1

”,“J

2

”and“J

3

”(gs.2.8,2.9)with

thosemostsuitableforthekindofgasforwhichitistobeused.

• Dualburneronly(g.2.9):

Ret

thecoverplate“D”andscrewtheno.2xingscrews

“C”;thenrettheinnercrownamespreader“B”andscrewtheno.3xingscrews“A”

• Rettheamespreaders,theburnercapsandthepansupports.

The burner are conceived in such a way so as not to require the regulation of the

primary air.

SECOND ORIFICE

DEUXIEME ORIFICE

A

A

A

B

C

C

D

J

2

J

3

Fig. 2.9

J

1

Fig. 2.8

SEMI-RAPID BURNER

DUAL BURNER

INJECTORS TABLE

NOMINAL

POWER

REDUCED

POWER

LP/PROPANE

11”W.C.P.

NATURAL GAS

4”W.C.P.

BURNERS BTU/hr BTU/hr

Øinjector

[1/100mm]

Øinjector

[1/100mm]

Semirapid(SR) 8000 1500 85 139

Dual(D)

Innercrown 2100 1000

42(*)

115(**)

70(*)

200(**)

Inner&outercrown 17000 6500

(*) innercrown(“J

2

”ingure2.9)

(**) outercrown(“J

3

”ingure2.9)