— 4 —

LOCATION

Do not obstruct the air flow into and around the cheesemelter. This air flow is necessary for proper

combustion of gases and for ventilation of the cheesemelter.

Do not obstruct the flow of flue gases from the flue duct of the cheesemelter. It is recommended that

the flue gases be ventilated to the outside of the building through a ventilation system installed by

qualified personnel.

If mounted over a range equipped with casters, the minimum width of the range is 60 inches and the

following restrictions apply:

1. The installation shall be made with a connector that complies with the Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69 (latest edition), and a quick-disconnect device that

complies with the Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41

(latest edition).

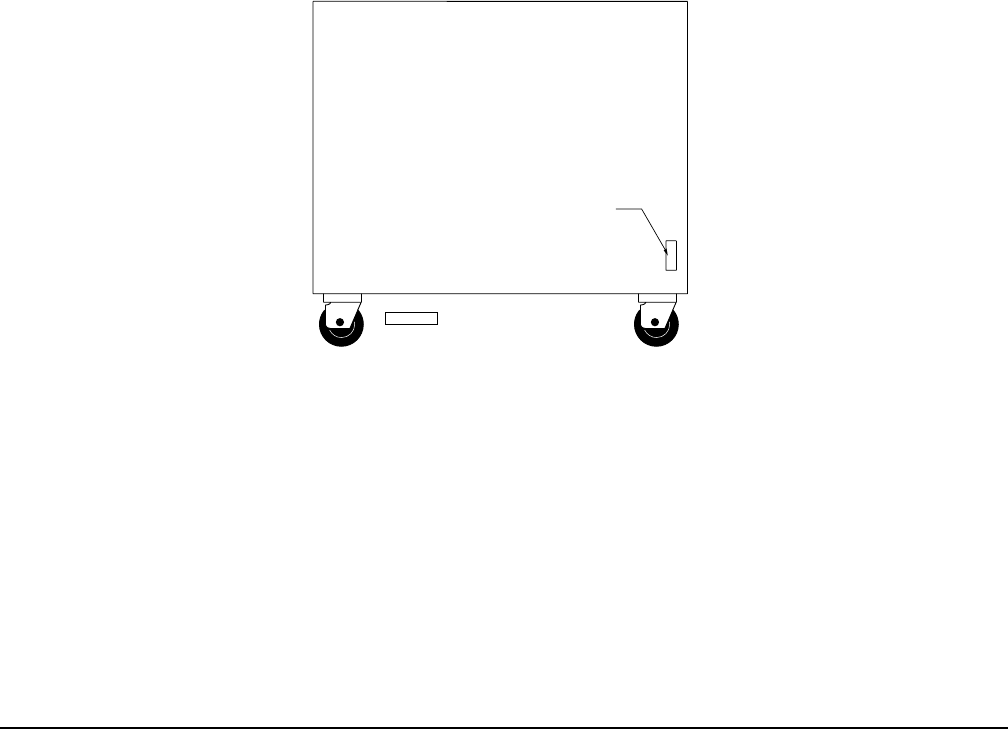

2. Provide a restraining device for the gas line to limit the movement of the range without depending

on the connector and the quick-disconnect device or its associated piping to limit the range

movement. Attach the strain relief to the rear of the range (Fig. 1).

If disconnection of the strain relief is necessary, turn off the gas supply before disconnection.

Reconnect this restraint before turning the gas supply on and returning the range to its installation

position.

Fig. 1

Maintain a minimum 6" clearance at the sides and rear next to combustible and non-combustible

construction. Maintain an 18" clearance from the end of the cheesemelter flue vent to the filters of the

hood venting system.

Keep the area free and clear of all combustible substances.

The installation location must allow adequate clearances for servicing and proper operation. A

minimum front clearance of 18" is required.

Make sure there are no cross currents within the kitchen (such as wall-type fans, open windows next

to the cheesemelter, or fans blowing directly on the cheesemelter).

PL-51219

CONNECT GAS LINE

STRAIN

RELIEF HERE