SERVICE PROCEDURES AND ADJUSTMENTS

Certain procedures in this section require electrical test or measurements while power is applied

to the machine. Exercise extreme caution at all times. If test points are not easily accessible, disconnect power and

follow lockout / tagout procedures, attach test equipment and reapply power to the test.

TEMPERATURE CONTROLLER

TEST

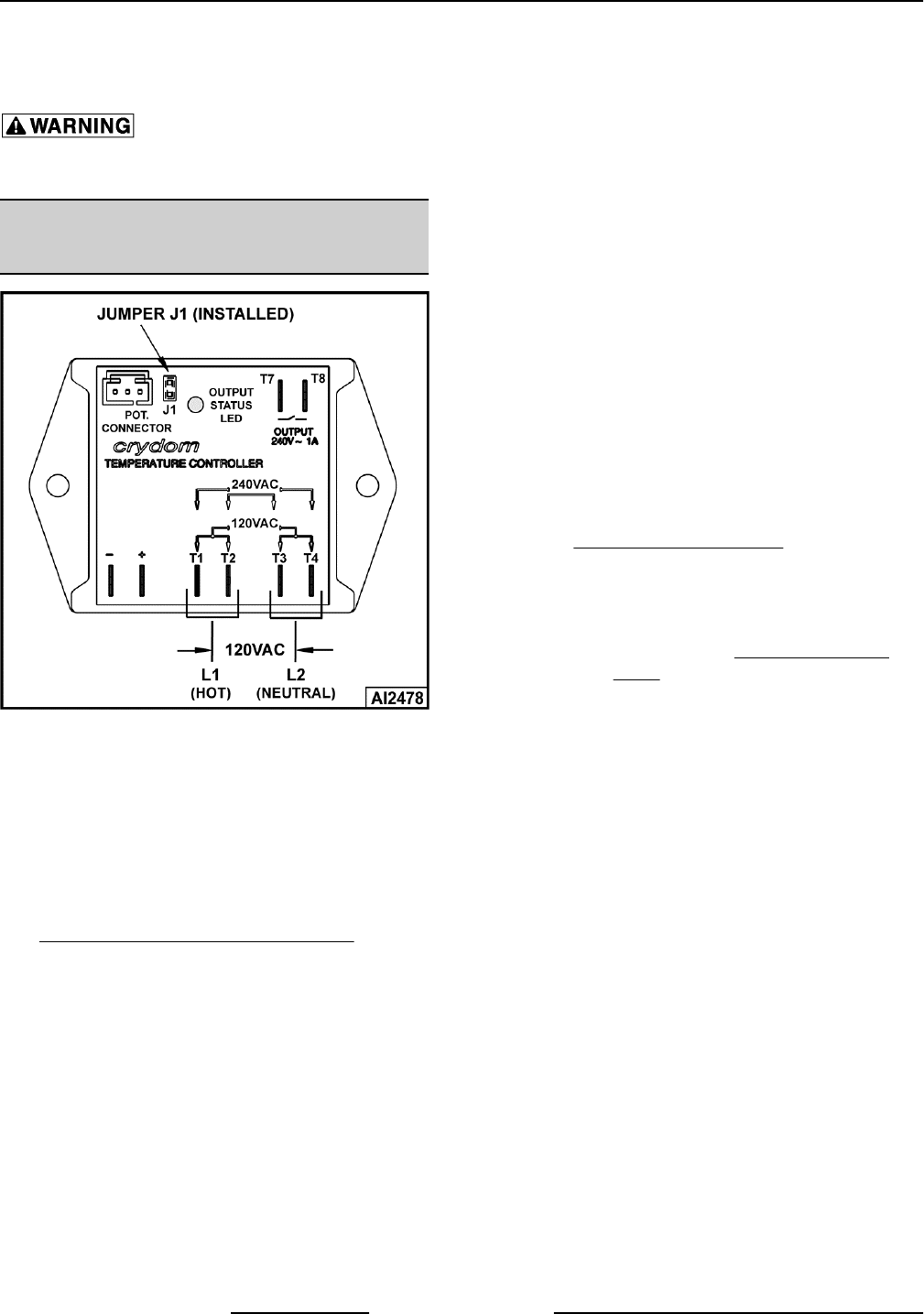

Fig. 33

1. Place kettle in full upright position (tilting models

only).

2. Set temperature dial to lowest setting. Kettle

must be below 110°F before verifying the

potentiometer output to the controller is good

over the full range of temperature dial travel.

3. Access the temperature controller as outlined in

ELECTRICAL PANEL COMPONENTS.

4. Check all lead wires for secure connections to the

controller terminals. Wiring harness lead wires

must be connected to T1-T2 and T3-T4 for proper

input to controller.

5. Re-connect power to the machine.

6. Turn power switch on.

7. Verify temperature controller is receiving

120VAC at terminals T1-T3 and T2-T4 and

machine is properly grounded.

8. Slowly turn temperature dial to the highest setting

and monitor heat light over the full range of travel.

A. Verify heat light (amber) comes on, blower

motor comes on and transformer is powered

(120VAC).

B. If the components listed above are

functioning properly, then output from T8 on

controller should be present. As long as

transformer output voltage is correct

(24VAC), heat circuit is powered and the

ignition sequence to light the burner will

start.

C. If heat light does not remain on or flashes

momentarily as temperature setting is

slowly increased, verify condition of

potentiometer as outlined under

POTENTIOMETER TEST.

D. If heat light or blower motor is not coming

on; or transformer is not powered.

1) Verify condition of thermocouple as

outlined under THERMOCOUPLE

TEST.

NOTE: Temperature controller will de-energize

internal relay and turn off the output status LED if the

circuitry detects an open thermocouple. LED will begin

to flash 3 times, pause, then repeat the flash sequence

to indicate the open thermocouple condition.

2) Check lead wire connections at the

component that is not functioning (heat

light, blower motor or transformer).

3) Verify power at the component that is

not functioning. If power is present,

determine if the component is

malfunctioning. If power is not present

at any of the components, continue

with procedure.

9. Disconnect lead wire from terminal T7 on the

controller.

A. Verify 120VAC between lead wire from T7

and ground. If correct, re-connect lead wire

to terminal T7 and continue with procedure.

B. If incorrect, check pressure switch (1PS)

and water level controller (WLC LLCO).

10. Disconnect lead wire from terminal T8 on the

controller.

K Series Gas Kettles 2/3 Jacketed Stationary and Tilting - SERVICE PROCEDURES AND ADJUSTMENTS

F45461 Rev. A (0713) Page 18 of 44