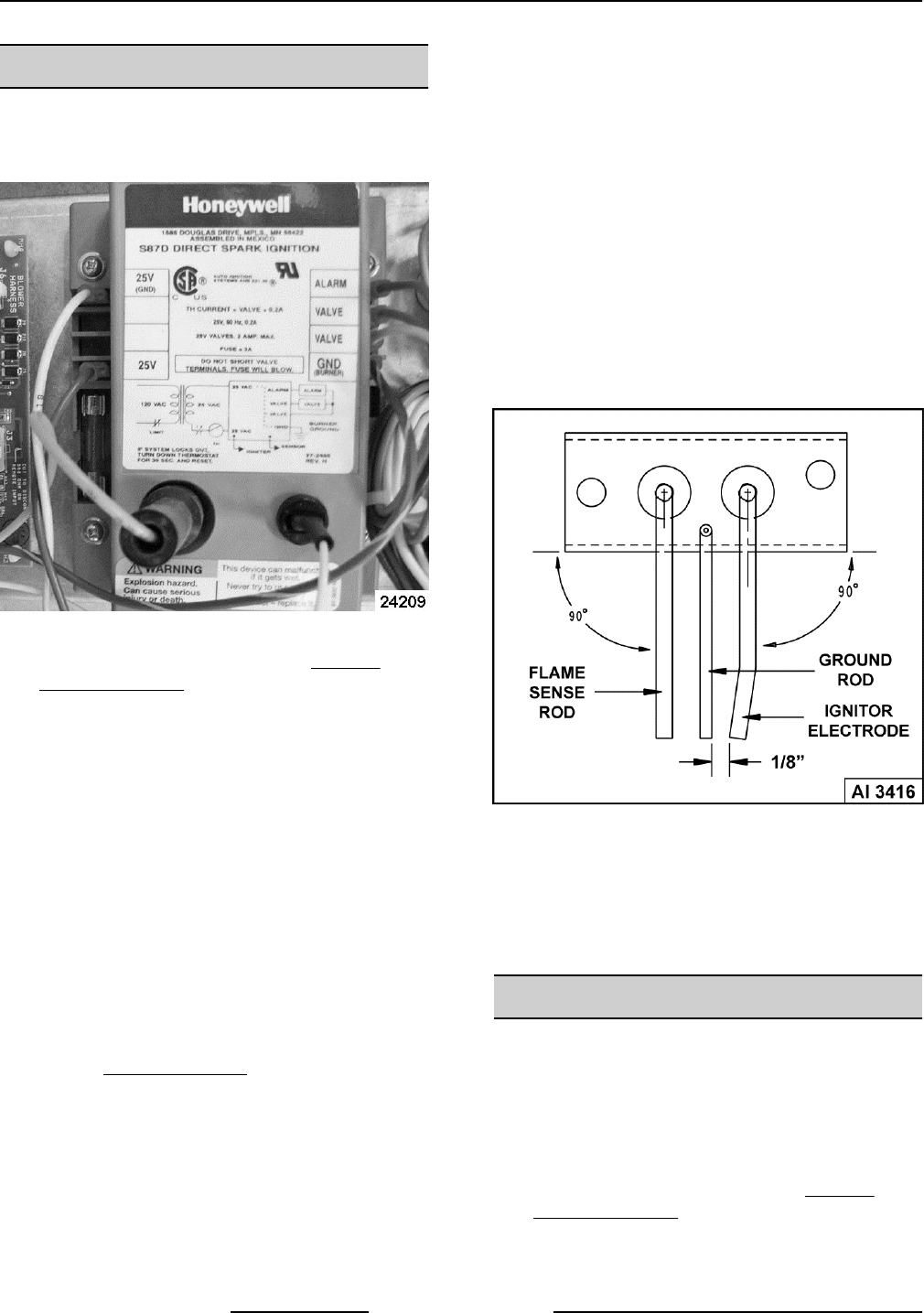

SPARK IGNITION TEST

If the ignition control module is not generating a spark

or the spark is not sufficient to light kettle burner,

perform the following test.

Fig. 42

1. Access ignition control module in KETTLE

CONTROL AREA.

2. Turn the on/off switch on and set the temperature

dial to call for heat. Tilting models must be in the

full upright position.

3. Verify the ignition control module is receiving

24VAC between terminals 25V & 25V GND.

A. If voltage is present, turn the on/off switch

off and proceed to step 4.

B. If voltage is not present, see schematic

diagram.

4. Disconnect power to the machine.

5. Verify all electrical connections (including

ground) on the ignition control module are

secure.

6. Access SPARK IGNITOR.

7. Verify the ground connection on spark ignitor is

clean and secure. The ground connection should

have good metal to metal contact.

8. Remove spark ignitor and check the following:

A. Inspect the ceramic insulator on spark

ignitor electrode for cracks or evidence of

exposure to extreme heat, which can permit

leakage to ground. If either of these

conditions exists, then install a replacement

spark ignitor.

B. Inspect the spark ignitor electrode and

ground rod for contaminates, or corrosion.

Clean those surfaces as necessary.

C. Spark gap between the spark ignitor

electrode and ground rod should be

approximately 1/8". If the gap is outside of

this dimension, bend the spark ignitor

electrode as necessary, to make the

adjustment.

Fig. 43

D. Check the ignitor wire connection for

tightness and damaged insulation. If the

ignitor wire appears to be damaged, then

install a replacement ignitor wire.

9. Install spark ignitor and reconnect ignitor wire.

FLAME SENSE CURRENT TEST

NOTE: You must complete the SPARK IGNITION

TEST prior to checking flame sense current.

If kettle burner lights but will not maintain flame,

perform the following test.

1. Turn the on/off switch off.

2. Access ignition control module in KETTLE

CONTROL AREA.

K Series Gas Kettles 2/3 Jacketed Stationary and Tilting - SERVICE PROCEDURES AND ADJUSTMENTS

F45461 Rev. A (0713) Page 24 of 44