ELECTRIC BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

F35410 (May 2003) Page 16 of 32

12. Repeat the average temperature calculation for

up to three attempts. Allow the pan to cycle at

least two times between adjustments before

performing the calculation.

13. If calibration is unsuccessful, the controller may

be malfunctioning and cannot be adjusted

properly. Install a replacement temperature

controller and check calibration.

TEMPERATURE CONTROLLER

TEST

NOTE: The controller is powered whenever supply

power is connected to the machine.

1. Lower the pan to the full down position.

2. Access the temperature controller as outlined in

REMOVAL AND REPLACEMENT OF PARTS.

3. Re-connect power to the machine.

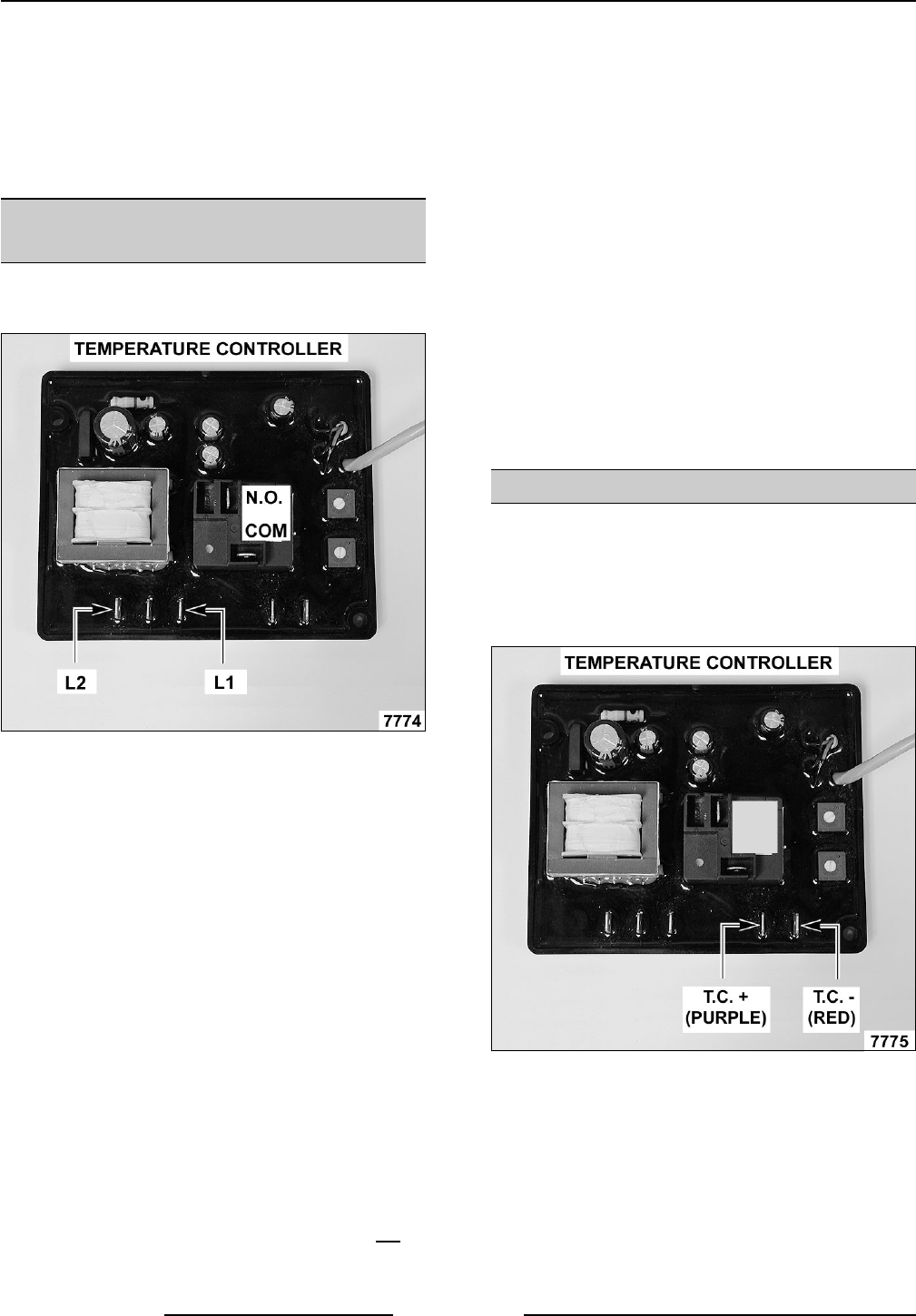

4. Verify temperature controller is receiving

120VAC at terminals L1 & L2, polarity is correct

and machine is properly grounded.

5. Turn on/off switch on and set temperature dial

to 250/F.

6. Verify heat light (red) comes on and all heating

elements are energized.

A. If heat light and heating elements energize

but turn off within 10 seconds, verify

condition of thermocouple as outlined

under THERMOCOUPLE TEST.

NOTE: Temperature controller will de-energize

internal relay if the circuitry detects an open

thermocouple.

B. If heat light and heating elements do not

energize, verify internal relay contacts are

operating properly.

7. Disconnect lead wire labeled HT.0 from the

COM terminal on the controller.

8. Verify 24VAC between the disconnected HT.0

lead wire and ground.

A. If correct, re-connect lead wire to COM

terminal and proceed to step 9.

B. If incorrect, check transformer and the

on/off switch for proper operation.

9. Disconnect lead wire labeled HT.1 from the

N.O. terminal on the controller.

10. Verify 24VAC between N.O. terminal on the

temperature controller and ground.

A. If correct, internal relay contacts are

functioning properly. Reconnect lead wire

to the N.O. terminal. See Troubleshooting.

B. If incorrect, install a replacement

temperature controller and check for

proper operation.

THERMOCOUPLE TEST

1. Access the temperature controller as outlined

in REMOVAL AND REPLACEMENT OF

PARTS.

2. Remove thermocouple lead wires from

temperature controller.

3. Check the thermocouple for resistance.

A. If meter reads an overload (OL) condition

(open), or zero ohms (short) replace the

thermocouple and check temperature

controller for proper operation.

4. If resistance is measured, thermocouple is

good.