CLOSED

OPEN

19

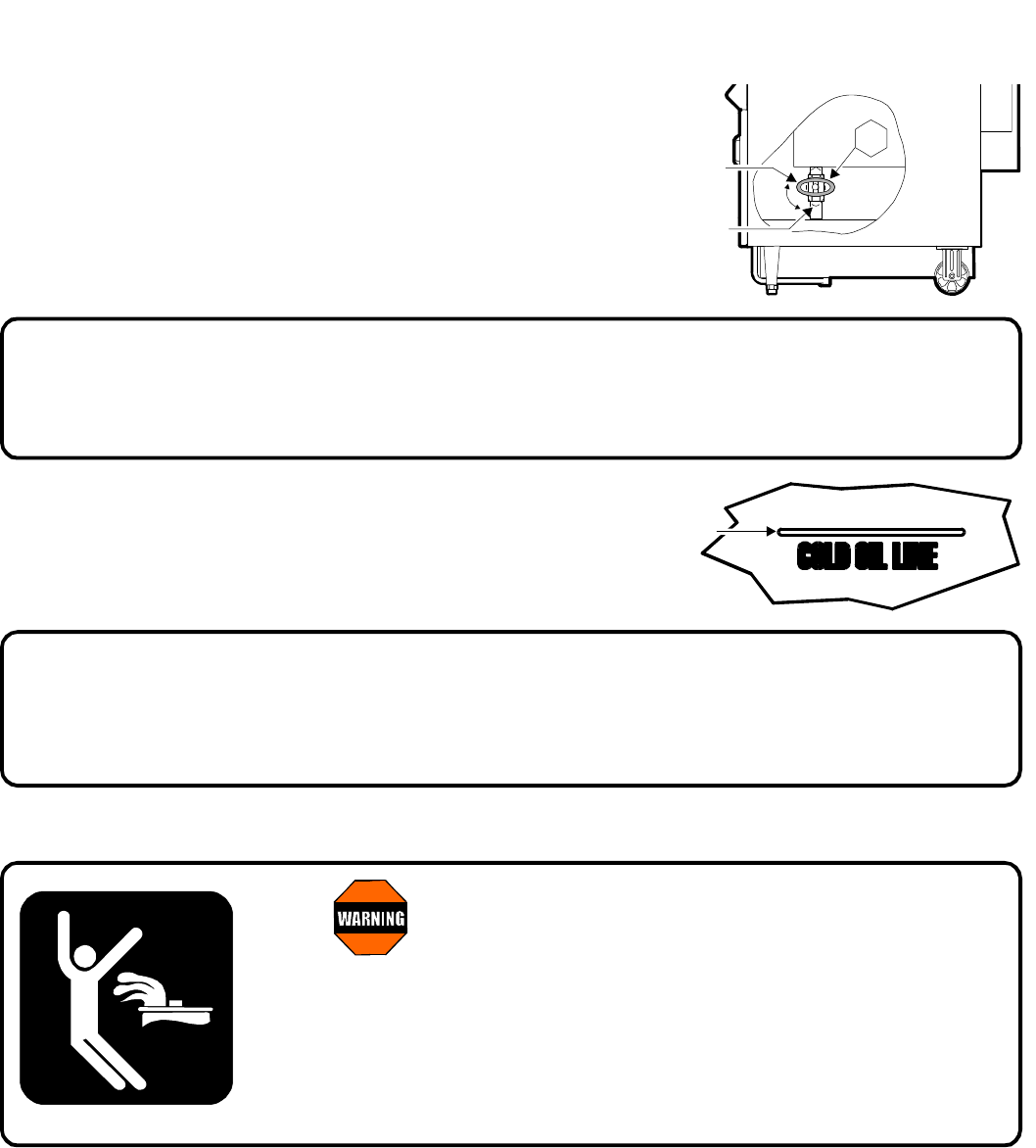

5. Close the OVAL DRAIN VALVE HANDLE (item 19)

by turning the handle to the CLOSED position.

9

NOTE: This fryer is designed for LIQUID SHORTENING ONLY. DO NOT USE SOLID

SHORTENING OR LARD. Solid shortening will solidify in the filter reservoir and filter

pump. This condition will render the filter system inoperable. Repairs caused by the use

of anything other than liquid shortening are not covered under warranty.

6. Fill the FRYPOT to the COLD OIL LINE

in the FRYPOT with cold commercial

quality LIQUID SHORTENING.

This requires 60lbs. of oil.

IMPORTANT: Remember to fill the fryer to the COLD OIL LINE with fresh liquid shortening

prior to turning the POWER SWITCH to the FRYER position.

Energizing the fryer without oil can cause serious damage.

Damage due to operating the fryer without oil is NOT covered by warranty.

.

7. Check operation of FRYER and all CONTROLS. See OPERATING INSTRUCTIONS, page10.

8. DETERMINE MAXIMUM LOAD WEIGHT: For operational safety, it is very important to

determine the maximum load weight for the specific operation. This can be accomplished by

starting out with small loads and gradually increasing to the largest load size which allows a

complete cook cycle without oil foaming out of the FRYPOT.

The weight of product which can be safely cooked in this fryer will vary

with oil level, product moisture content, oil temperature, and other various

conditions. See Determine Maximum Load Weight below.

FAILURE TO OBSERVE THIS WARNING WILL RESULT IN HOT OIL

RELEASE FROM THE FRYER.

HOT OIL WILL CAUSE SEVERE BURNS ON CONTACT.

POTENTIAL FOR OIL OVERFLOW

COLD OIL LINE

FILL TO THIS LINE WITH COLD OIL