123

8

8

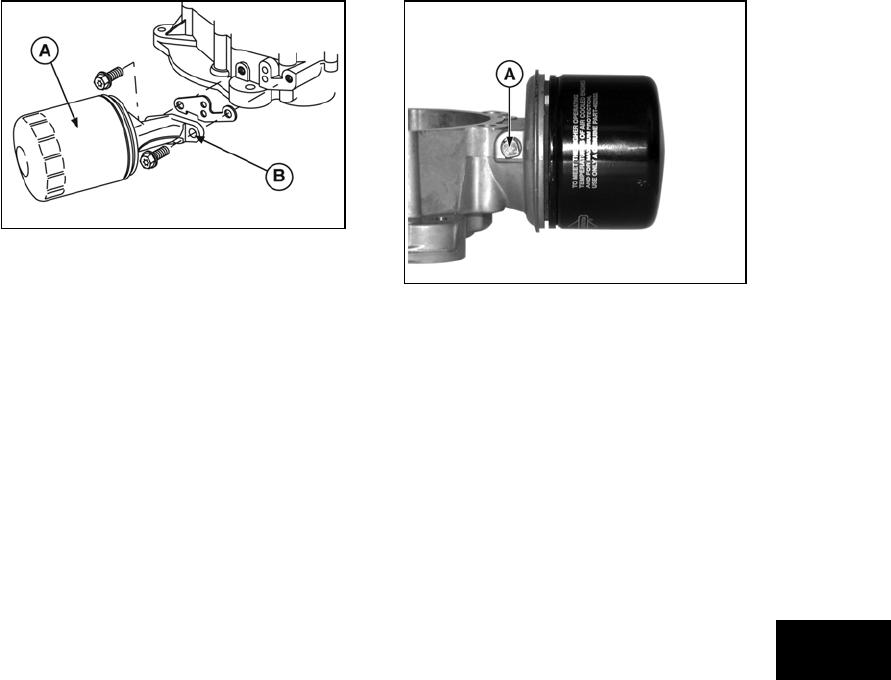

Figure 24

Inspect

1. Check adapter for cracks or damage to

the sump and filter mounting surfaces.

Replace adapter if necessary.

2. Clean all oil passages in adapter and in

sump.

Install

1. Using new gasket, place adapter on sump

and install screws. Torque screws to

values listed in Section 12 - Engine

Specifications.

2. Apply a thin film of clear oil filter gasket.

Install filter until gasket contacts the

adapter, then tighten 1/2 to 2/3 turn more.

Oil Pressure Switch

The optional low oil pressure switch is located on

the sump or oil filter adapter (A, Figure 25).

The switch should open at approximately 4-5 PSI

(.27-.34 bar) for Model Series 28N700, 28P700,

287700, 310700, 312700, 313700, 330700.

Model Series 28N777 Type 1194-E1 opens at

approximately 9-13 PSI (.62 -.90 bar).

Figure 25

Test Oil Pressure Switch

1. Unscrew the switch to remove it for

testing.

2. Connect one test meter lead to the switch

terminal and the other lead to the metal

body of the switch.

3. The meter should indicate continuity.

4. Replace the switch if there is no continuity.

5. Install switch and tighten to values given in

Section 12 - Engine Specifications.

NOTE: Do not use sealing tape on the switch

threads.

Oil Gard Systems

Horizontal Model Series 110000,

120000, 150000, 200000, 210000

The Oil Gard System consists of:

• Oil Sensor (A, Figure 26 and Figure 27)

(located inside crankcase)

• Module (B)

• Three-terminal stop switch (C)

• Connecting wires

If the oil level is low, the Oil Gard sensor will

close. The engine cannot be restarted until

sufficient oil is added. If equipped with a lighted

rocker switch, the light will flash when the starter

is actuated, indicating insufficient oil in the

crankcase.