148

9

11

PISTONS, RINGS, & CONNECTING RODS

Remove Piston and Connecting Rod

1. Carefully remove any carbon or ridge at

top of cylinder bore to prevent ring

breakage.

2. Remove rod bolts and connecting rod cap

(A, Figure 1).

3. Push piston and rod assembly out through

top of cylinder bore.

Figure 1

Disassemble

1. Rotate pin retainer until one end is

exposed in notch in pin bore.

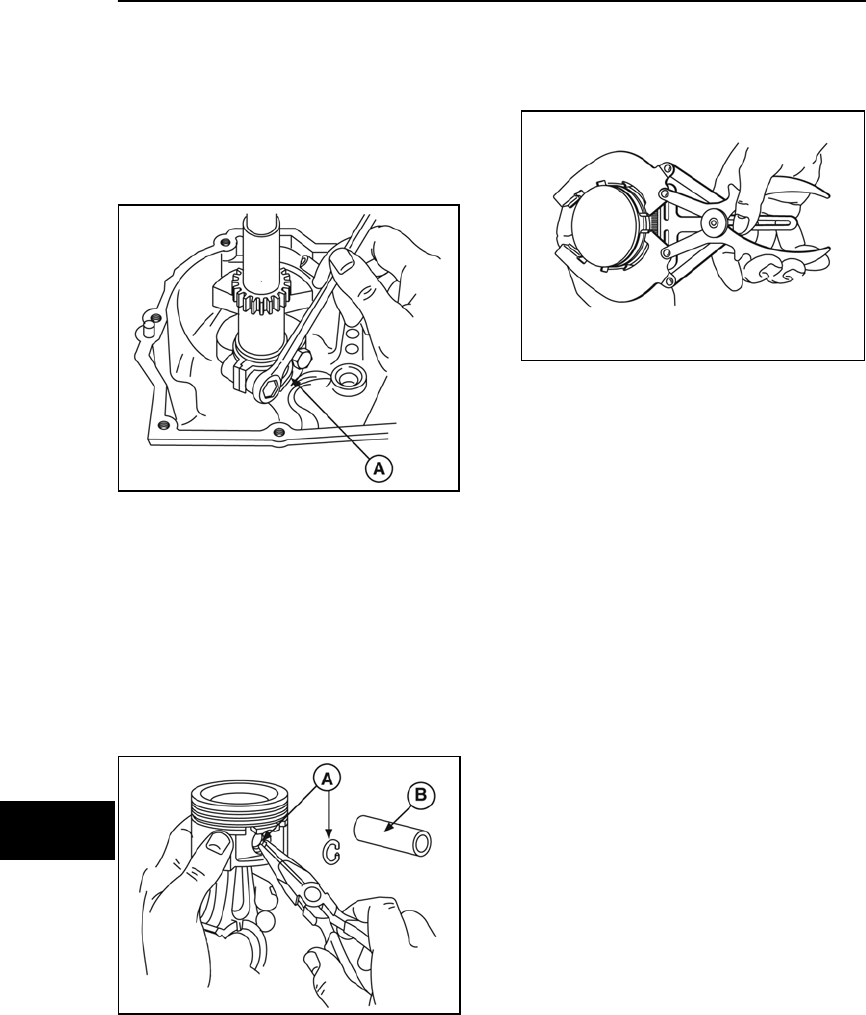

2. Remove the two retainer pins (A, Figure 2)

with needle nose pliers.

NOTE: Some pistons have a shoulder stop on

one side and a single retainer.

3. Slide out pin (B) from opposite side and

remove connecting rod from piston.

Figure 2

4. Using Piston Ring Expander #19340

(Figure 3), remove rings one at a time.

Note the order and orientation of the rings

before removal.

Figure 3

NOTE: Some oil control rings consist of two thin

steel rails and a spring expander. These must be

removed by hand as follows:

• Grasp one end of the upper steel rail and

wind the rail from the oil ring groove into

the center ring groove. Repeat into the

top ring groove and then off the piston.

• Remove the spring expander, then

remove the lower steel rail.

Inspect

Check Piston and Pin

1. Inspect piston for scoring, galling, or other

damage. Replace piston if necessary.

2. Using a dial caliper or plug gauge,

measure the pin bore diameter. Compare

with reject dimensions listed in Section 12

- Engine Specifications. If pin bore

exceeds reject dimensions, replace the

piston.

3. Measure outside diameter of pin and

compare to the reject dimension listed in

Section 12 - Engine Specifications. If pin is

smaller that the reject dimension, replace

the pin.

4. Clean carbon from top ring groove.

5. Place NEW ring in groove (Figure 4) and,

using a feeler gauge, measure space

between ring and ring land. Compare with

reject dimensions listed in Section 12 -