127

9

9

Cleaning Cylinder

1. Wash the cylinder thoroughly in a solvent

such as kerosene or other commercial

solvent.

2. Wash cylinder again using a stiff brush

with soap and hot water.

3. Rinse cylinder thoroughly with hot running

water.

4. Repeat washing and rinsing until all traces

of honing grit are gone.

NOTE: Honing grit is highly abrasive and will

cause rapid wear to all of the internal

components of the engine.

When cylinder and crankcase have been

thoroughly cleaned, use a clean white rag to

wipe the cylinder bore. If honing grit is still

present, it will appear as a grey residue on the

rag. Re-wash and rinse entire cylinder then

check again. When there is no trace of honing

grit on the rag, the cylinder is properly cleaned.

Oil the cylinder bore to prevent rusting.

MAIN BEARINGS

Check Bearings

Briggs & Stratton OHV engines are equipped

with plain bearings machined into the cylinder or

cover/sump, DU™ bearings, or ball bearings to

support the crankshaft.

Check Plain Bearings

Machined bearings are not repairable. If a

machined bearing is scored or worn, the cylinder

or cover/sump must be replaced.

Check DU™ Bearings

Main bearings should be replaced if scored or if

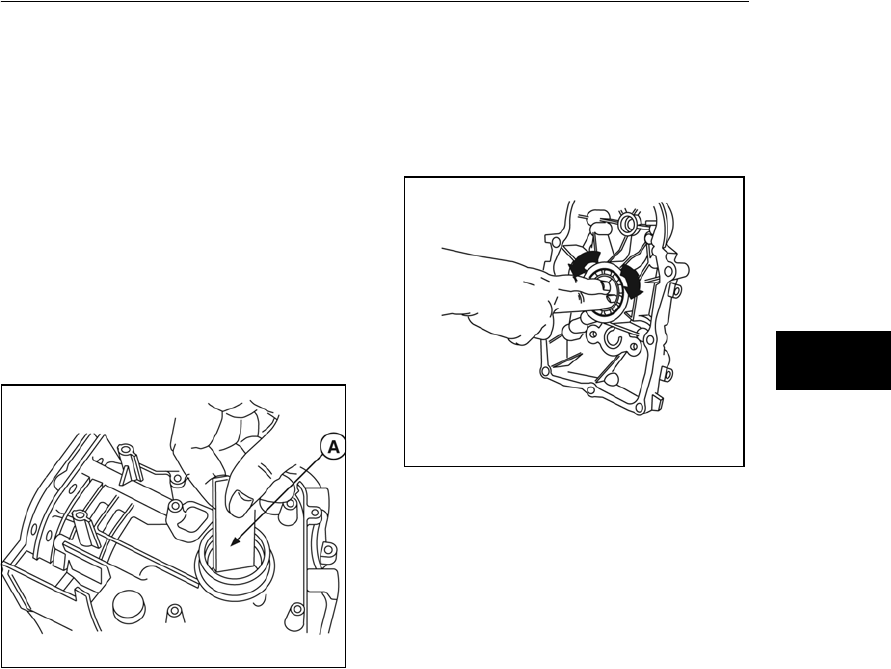

plug gauge (A, Figure 4) will enter bearing. Try

gauge at several locations in bearing.

Figure 4

Check Ball Bearings

Ball bearings must rotate freely. If any rough

spots are felt, the ball bearing must be replaced

(Figure 5).

NOTE: DO NOT reuse ball bearings. The

bearing races are usually damaged during

removal.

Figure 5

NOTE: Standard and reject sizes for the main

bearings are shown in Section 12 - Engine

Specifications.

Check Camshaft Bearings

The camshaft is supported by machined

bearings which are not serviceable. Check

camshaft bearings with Plug Gauge #19164. If

gauge can be inserted 1/4” (6.4 mm) or more,