43

2

2

ELECTRIC STARTERS

Before assuming an electric starter requires

service, check the engine for freedom of rotation

by removing the spark plug and turning the

crankshaft over by hand. Any belt, clutch, or

other parasitic load will affect the starter cranking

performance, so ensure their effects are

minimized.

The following list is given to aid in diagnosing

problems for 12 Volt and 120 Volt starting

systems.

1. Engine Cranks Slowly

• Parasitic load affecting performance

• Discharged, defective, or incorrect

battery (also, see alternators)

• Faulty electrical connection (battery

circuit)

• Dirty or worn starter motor commutator,

bearing, weak magnets, etc.

• Wrong engine oil viscosity for ambient

temperatures

• Defective starter clutch

• Band brake misadjusted

• Battery leads too long or wire diameter

too small

• Extension cord longer than 25 feet (7.60

mm) (120 volt AC only)

2. Engine Will Not Crank

• Faulty safety interlocks

• Discharged or defective battery

• Faulty electrical connections

• Faulty starter motor switch (open circuit)

• Open circuit in starter motor

• Defective rectifier assembly (120 Volt AC

only)

• Brushes sticking, etc.

• Faulty solenoid

• Blown fuse or tripped breaker at power

source.

3. Starter Motor Spins But Does Not Crank

Engine

• Sticking pinion gear

• Damaged pinion or ring gear

• Starter motor clutch slipping

• Incorrect rotation due to reversed motor

polarity (all motors rotate

counterclockwise, as viewed from pinion

gear)

4. Starter Motor Blows Fuses - (120 Volt

Starter Motor Only)

• Parasitic load

• Shorted rectifier assembly

• Shorted 120 volt extension cord to starter

motor

• Armature shorted

• Overloaded circuit

5. Starter Motor Spins But Will Not Stop

• Defective starter switch

• Defective solenoid

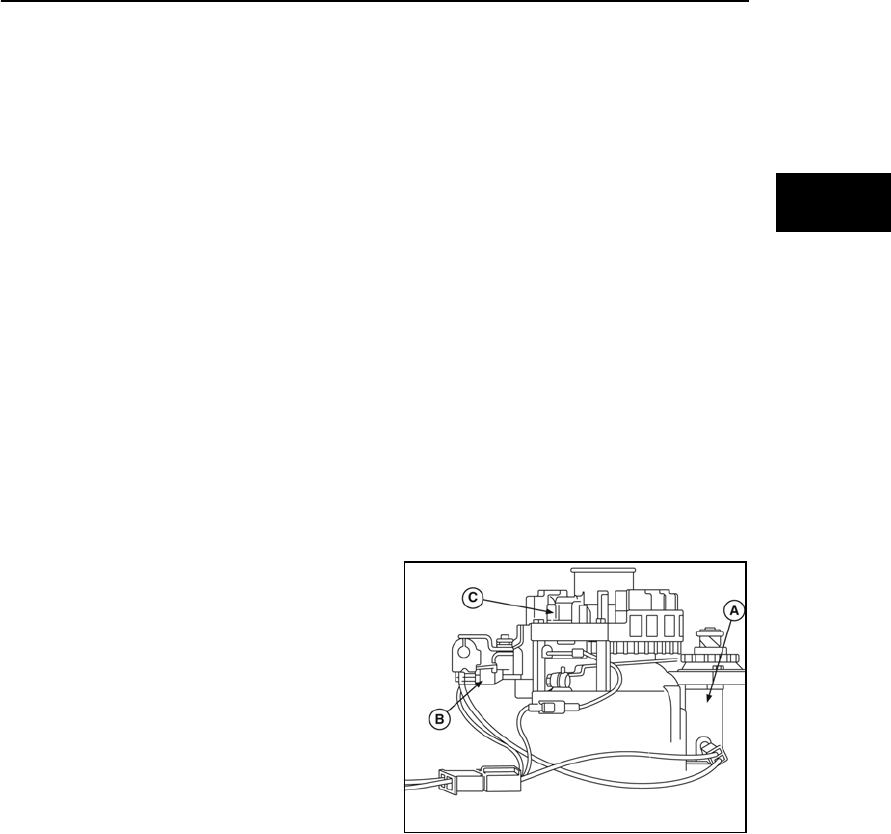

SYSTEM 3®, SYSTEM 4®

Model Series 97700, 99700, 110000,

120000

Both of these systems consist of a starter motor

(A, Figure 33), starter switch, interlock switch (B),

and solenoid (optional). When the starter switch

or solenoid is actuated, the battery supplies

power to the starter motor, cranking the engine.

When the engine is running, the alternator (C)

recharges the battery.

Figure 33

Check Starter Motor Drive and Clutch

When starter switch is activated, pinion gear

(A, Figure 34) should rise, engage flywheel ring

gear, and crank engine. The pinion gear must

rotate counterclockwise, as viewed from gear.

If starter motor drive does not react properly,

check helix (B) and pinion gear for free

operation.