16

5958 992 00

EN

• The appliance must be electrically grounded in accordance with

local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.2, as applicable.

The grounding conductor must therefore be connected to the

terminal marked Gon the connection terminal board. The

appliance must also be connected to an earth grounding

system.

This connection is made using the stop screw marked E

located on the outside of the appliance near the power cable

inlet.

The grounding wire must have a minimum cross-section of

8 AWG (10 mm

2

).

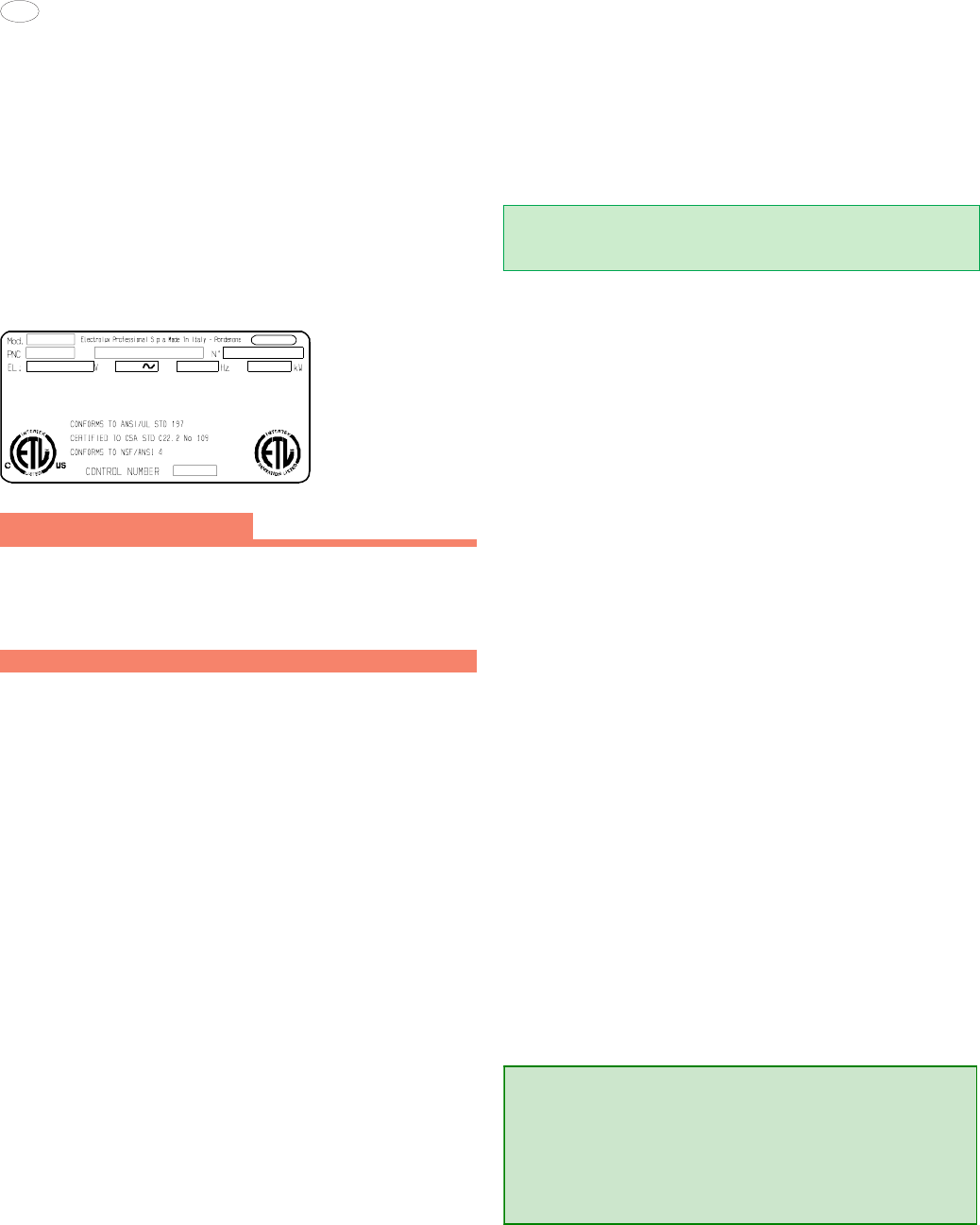

RATING PLATE

GROUNDING INSTRUCTIONS

::

::

:

This appliance must be connected to a grounded, metallic,

permanent wiring system, or an equipment grounding

conductor should be run with the circuit conductors and

connected to the equipment grounding terminal or lead on

the appliance.

3.1 POWER CABLE INSTALLATION

To connect the power cable to the appliance, proceed as follows:

Model 6 - 10 - 20 GN

• Remove the left side panel.

• Connect the cable to the terminal block as shown in the wiring

diagram attached to the appliance, and secure it with the special

cable gland.

The manufacturer declines any liability if the safety regula-

tions are not respected.

The manufacturer requires when stacking units each appliance

have its own branch circuit protection. An air-o-speed® unit stacked

with an air-o-chill® unit should have a separate circuit breaker for the

upper and lower units.

4. WATER CONNECTION

(See the installation diagrams at the beginning of this handbook)

This equipment is to be installed to comply with the applicable

Federal, State, Local plumbing codes, or the Basic Plumbing

Code of the Building Officials and Code Administrators

International Inc. (BOCA) and Food Service Sanitation Manual

of the Food and Drug Administration (FDA).

The oven has two separate inlets (“B” and “N”) for the supply

water.

The supply pipes of both inlets must be equipped with a me-

chanical filter and shutoff cock. Before installing the filters, it is

advisable to let a certain amount of water flow in order to clean

the pipe of any solid particles.

4.1 SUPPLY WATER CHARACTERISTICS

4.1.1 WATER INLET “N”.

Important (LEVEL A ONLY)

The water supply pipe must have an inside diameter of at

least 20 mm and be free of elbow unions.

The discharge steam condensation system can be fed with cold

water suitable for human consumption, having the following

characteristics:

- total hardness not exceeding 400ppm (40°fH); in LEVEL

A ovens equipped with CLEANING SYSTEM it is advisable to use

water of hardness not exceeding 5° French; for that purpose, a

water softener with automatic regeneration for installing on inlet

line “N” is supplied as an accessory by request.

- pressure between 22 to 36 psi (150-250 kPa); higher

pressures involve waste of water.

Note:

To check correct water installation, make sure the rotating wash

arm (CLEANING SYSTEM) does not turn below 100 rpm (120

max).

4.1.2 WATER INLET “B”.

(With feed pipe supplied)

The inlet for steam production must be fed with water suitable

for human consumption, having specific characteristics:

- total hardness between 5 - 50ppm (0.5 - 5 °fH) French

for reducing scaling inside the steam generator.

For that purpose, a water softener with automatic regeneration

for installing on inlet line “B” is supplied as an accessory by re-

quest;

it has a kit for sterilizing the resins (by further request).

- pressure between 22 to 36 psi (150-250 kPa); higher

pressures involve waste of water.

- chlorine concentration (Cl -) not high (acceptable refer-

ence value ~10 ppm), so as not to damage the steel structures

inside the oven.

- pH higher than 7.

For that purpose, a special filtering unit for installing on inlet line

“B” is supplied as an accessory by request. The purpose of this

unit is to reduce the water hardness to optimum values (below

50ppm "5 °fH") (optimum value), and therefore also serving as a

water softener.

- electric conductivity between 50 and 2000 µS/cm (68°F)

(20°C).

Important: The use of water treatment systems utilizing

methods different from those indicated by the manufacturer of

the equipment is not allowed and will completely invalidate the

warranty.

Likewise, dispensers of substances for preventing scale in

the pipes (e.g. polyphosphate dispensers) must not be

used because they can compromise correct machine

operation.

4.2 WATER DRAINING SYSTEM

The oven has an AIR-BREAK anti-backflow device inside to pre-

vent possible backflow from the drainage system entering the

internal pipes and the oven compartment. This allows the drain

pipe to be connected directly to the mains system or discharging

into a floor grate.

The drain pipe (rigid or flexible type) can be run to the side or