F200F200

F200F200

F200

F300F300

F300F300

F300

Output (kg/ 24 hours) 215 320

Bin Storage Capacity (kgs) 150/ 210 150/210

Cubes Per Cycle (kgs) 2.3 2.3

Standard Cube Size 24mm x 24mm x 26mm 24mm x 24mm x 26mm

Cycle Time (minutes) 16 11

Amps start/run 29/5.5 31/8.5

Watts Consumption 1000 1600

Machine Weight net / gross (kgs) 70/85 73/88

Refrigerant R404A R404A

Refrigerant Charge 500 grms 850 grms

Discharge Pressure Freeze Cycle Max 17 bar/ Min 15 bar Max 18 bar/ Min 16 bar

High Pressure Cut Out 30 bar 30bar

High Pressure Safety Switch Cut in 20 bar/ Cut Out 33 bar Cut in 20 bar/ Cut Out 33 bar

Suction Pressure Freeze Cycle Start 3.6 bar/ End 2.3 bar Start 3.6 bar/ 2.5 bar

Compressor Amps Freeze Mode Start 4.2 amps/ End 3.4 amps Start 7.0 amps/ End 5.2 amps

Voltage 230/50/1 230/50/1

Reservoir Water Level 40mm to 45mm 40mm to 45mm

Water inlet Connection

3

/

4

gas

3

/

4

gas

1. Specification

1.1 Capacities

1.2 Installation Notes.

Allow 15cm minimum space at the sides and back for ventilation.

Bin Installation

The F200 and 300 fit the New SB150 Bin.

The F200 and F300 can be fitted to the New SB210 Bin but a KN311 Lid is required.

The F200 and F300 can be fitted to the Old SB150 Bin but a SB150 frame is required, as the F200 and F300 are smaller than the Old SB150

Bin.

The F200 and the F300 can be fitted to the Old SB210 Bin provided the KN310 lid is fitted first. However it is necessary to re-drill the lid to

secure the machine to it.

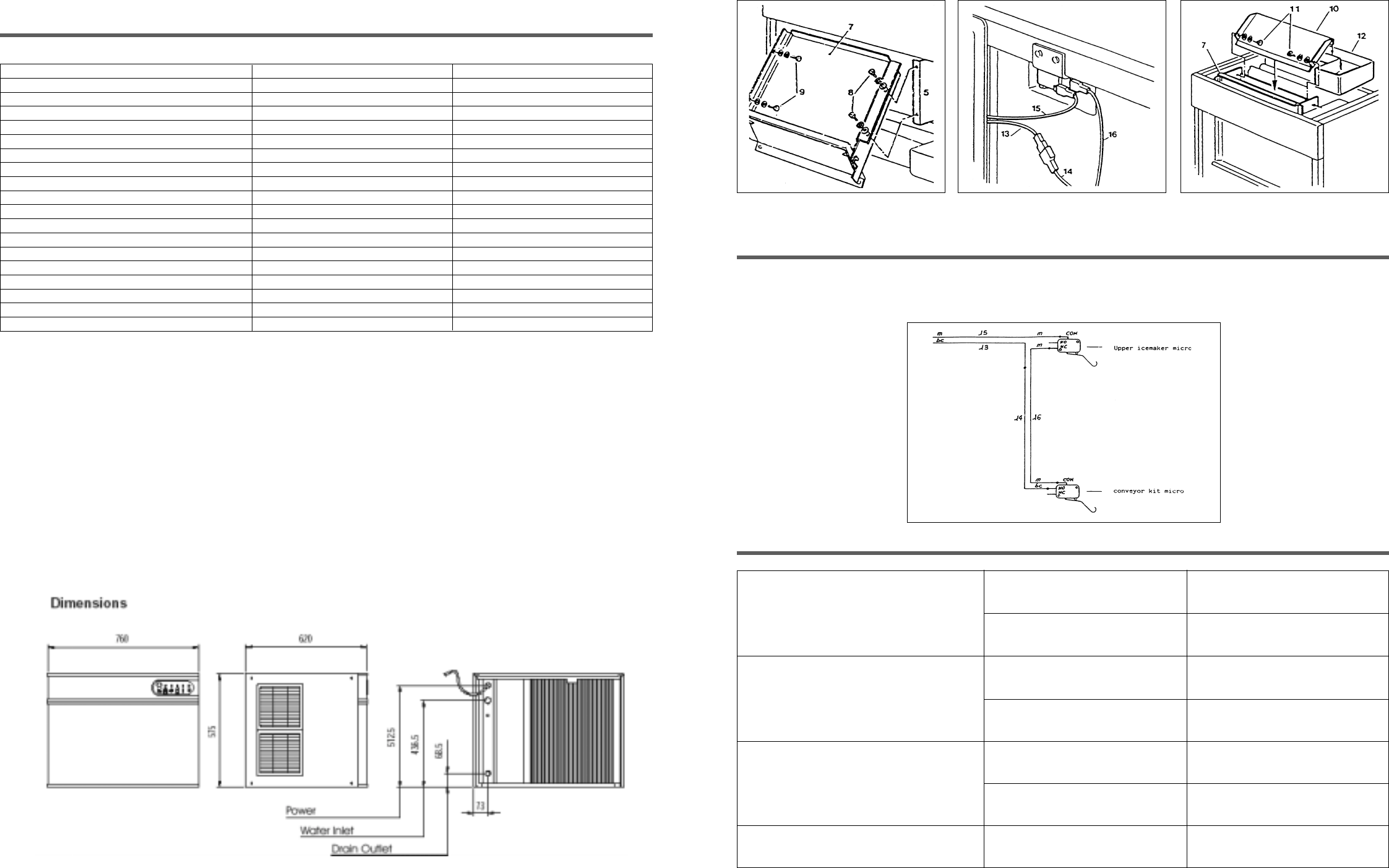

1.3 Stacking Installation.

To stack a Modular Cuber onto the present one, first remove the top panel from the lower machine.

Add a bead of food grade silicone sealer to the top edges of the lower units freezing compartment.

Lift the top machine onto the bottom machine, (the use of a mechanical lift is recommended).

Align the two machines, and using the two screws supplied in the hardware package supplied with the top machine, fasten the two together

through the fixing holes on either side of the machines.

Fit the Stacking Kit KS into the bottom machine as per the instructions supplied with the kit.

Using food grade silicone sealer, seal the edges between the freezing compartments of the top and bottom machine so as to avoid any

possible leakage of water through the join.

4

F200 & F300 Modular Ice Cuber

1. Detach the light blue (No.13) cable of the upper ice maker; this cable is connected to the NC contact (usually closed) of the micro.

Connect it to the light blue (No.14) cable which is joined to the NO contact (usually opened) of the conveyor kit micro.

2. Connect the brown (No.16) cable which comes from the COM (common) contact of the conveyor kit micro to the NC contact (usually

closed) of the upper ice maker micro.

Fig.4

Fig.5 Fig.6

25

14. Guidelines for Icemaker Bin Lids

FMIC 180 HEAD

FMIC 260 HEAD

FMIF 220 HEAD

FMIF 550 HEAD

SB 150 BIN

SB 210 BIN

SB 150 BIN

SB 210 BIN

SB 150 BIN

SB 210 BIN

SB 210 BIN

NO BIN LID

KN 310 BIN LID

NO BIN LID

KN 310 BIN LID

NKF 200 BIN LID

NKF 310 BIN LID

NKF 310 BIN LID

13. Wiring Diagram Concerning The Connection Of Upper Ice Maker Micro

To Conveyor Kit Micro