2-7

When using thread compound, use very small amounts on male threads only. Use a pipe thread

compound that is not affected by the chemical action of LP gases (Loctite™ PST56765 Sealant

is one such compound). DO NOT apply compound to the first two threads. Doing so may allow

some of the compound to enter the gas stream, resulting in clogging of burner orifices and/or the

control valve.

2. Open the gas supply to the fryer and check all piping, fittings, and gas connections for leaks. A

soap solution should be used for this purpose.

3. Close the fryer drain valve and fill the frypot with water and boil-out solution to the bottom

OIL LEVEL line at the rear of the frypot. Light the fryer and perform the boil-out procedures

that are described in the “Lighting Instructions” and “Boiling Out the Frypot” topics found in

Chapter 3 of this manual.

DANGER

“Dry-firing” your unit will cause damage to the frypot and can cause a fire. Always

ensure that melted shortening, cooking oil, or water is in the frypot before firing your

unit.

4. The burner manifold pressure should be checked at this time by the local gas company or an

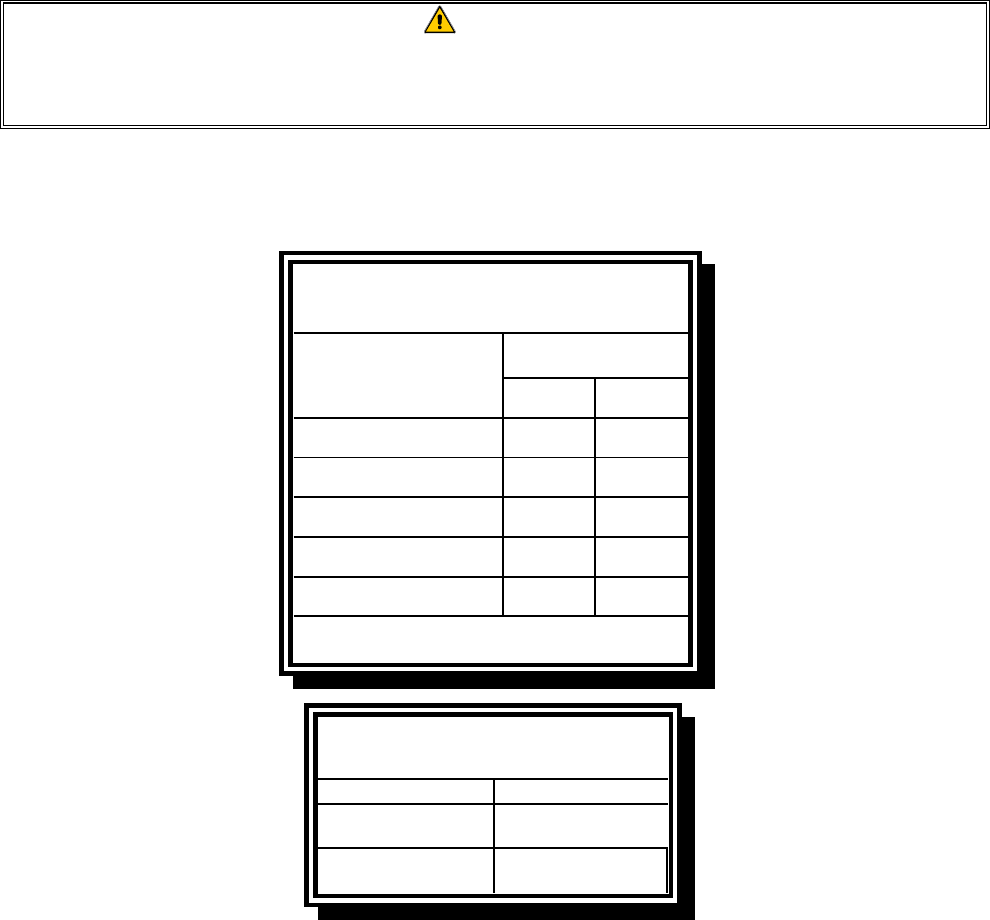

authorized service agent. The tables below and on the following page list the burner manifold

gas pressures for the various gas types that can be used with this equipment.

Gas

Single

Vat

Dual

Vat

Natural Gas Lacq

(G20) under 20 mbar

77

Natural Gas Groningue *

(G25) under 25 mbar

10 10

Natural Gas Groningue

(G25) under 20 mbar

10 10

Butane

(G30) at 28/30 or 50 mbar

17 17

Propane

(G31) under 37 or 50 mbar

20 20

CE Standard

Burner Manifold Gas Pressures

for Fryers Manufactured After April 1999

Pressure (mbar)

* Belgian G25 = 7,0 mbar (single or dual)

Non-CE Standard

Burner Manifold Gas Pressures

Gas Pressure

Natural

3" W.C.

0.73 kPa

Propane

8.25" W.C.

2.5 kPa

5. Check the programmed temperature thermostat setting. (Refer to chapter 4 CM7 Computer

Instructions) for the setpoint programming instructions for your particular controller.)