7-5

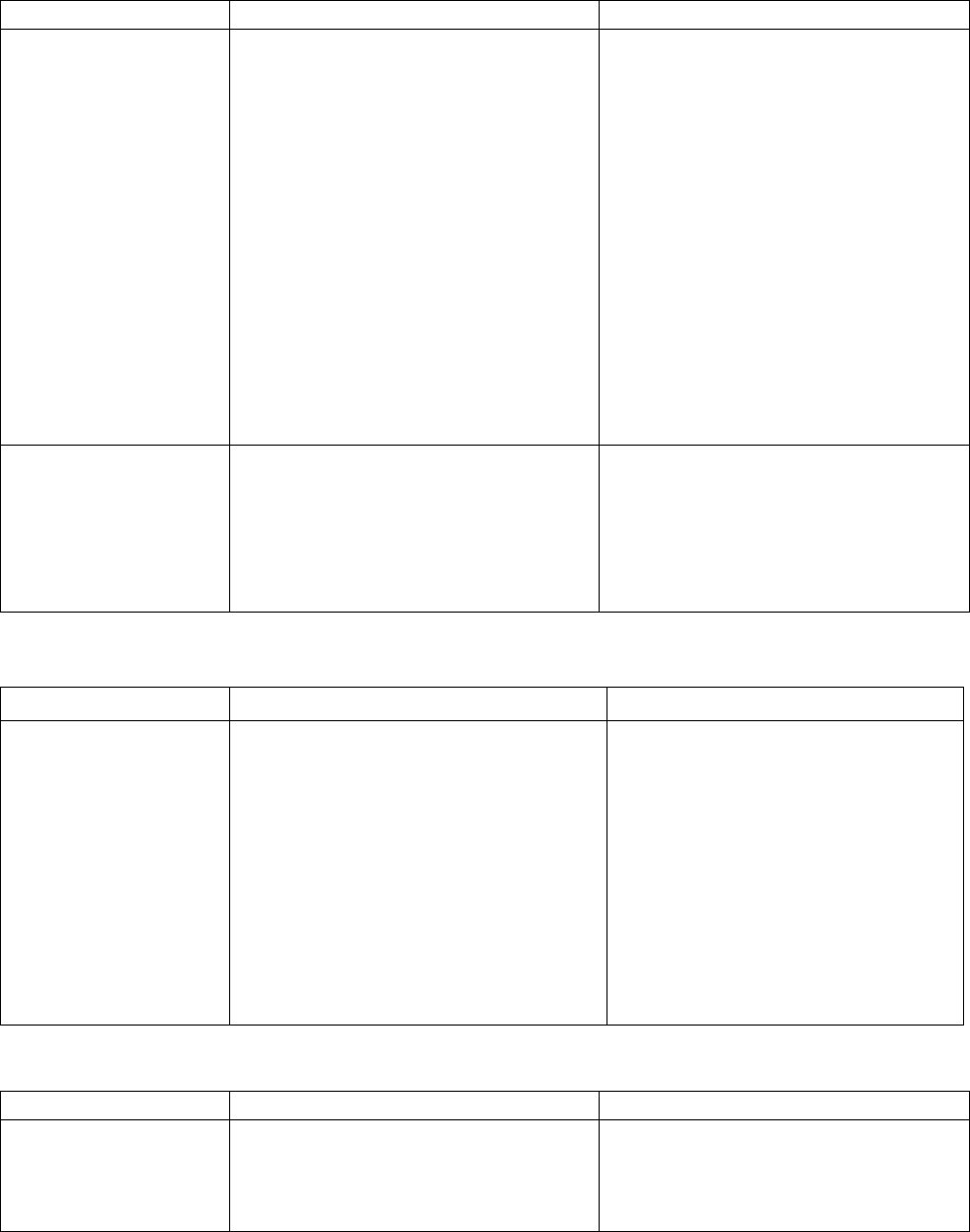

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

Filter pump runs,

but oil return is very

slow and bubbling

oil occurs.

A. Paper/screen clogged.

B. Improperly installed filter pan

components.

C. Attempting to filter with oil that

is not hot enough.

A. Paper/screen needs changed or

cleaned.

B. If using filter paper

configuration, verify that filter

screen is in bottom of pan with

paper on top of screen.

Verify that O-rings are present

and in good condition on filter

pan connection fitting.

C. In order to properly filter, the oil

should be at or near 350ºF

(177ºC).

Filter pump runs

but oil does not

return to frypot and

there is no bubbling

oil.

Blockage in filter pan suction tube.

Test: Close the drain valve and pull

the filter pan out from the fryer.

Activate the pump. If bubbling oil

occurs, there is a blockage in the

filter pan suction tube.

The blockage may be caused by

sediment buildup. Use a thin,

flexible wire to remove the

blockage. If the blockage cannot be

removed, call FASC.

7.2.4 Auto Top-Off Problems

Problem Probable Causes Corrective Action

Frypots won’t top

off.

A. Fryer temperature too low.

B. Temperature of oil too cold.

C. Supply line out of JIB.

D. CM7 not readdressed after ATO

switch was switched on.

A. Fryer temperature must be at

least 300°F (149°C).

B. Ensure that oil is above 70°F

(21°C).

C. Ensure supply line is in JIB.

D. Switch all CM7 computers off

and then on again to readdress

system.

If problem persists call your FASC.

7.2.5 Basket Lift Problems

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

Basket lift

movement is jerky

and/or noisy.

Basket lift rods need lubrication.

Apply a light coating of

Lubriplate

™

or similar lightweight

white grease to the rod and

bushings.