HIGH EFFICIENCY DECATHLON (HD) SERIES GAS FRYERS

CHAPTER 3: INSTALLATION

3-3

3.4 Gas Connections

DANGER

Before connecting new pipe to this appliance the pipe must be blown out thoroughly

to remove all foreign material. Foreign material in the burner and gas controls will

cause improper and dangerous operation.

U.S. NATIONAL CODE REQUIREMENTS

This equipment is to be installed in compliance with the Basic Plumbing Code of the Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation

Manual of the U.S. Food and Drug Administration.

This equipment is manufactured to use the type of gas specified on the rating plate attached to the

door. Connect equipment stamped "NAT" only to natural gas and that stamped "PRO" only to LP

(Propane) gas.

Installation shall be made with a gas connector that complies with national and local codes.

Quick disconnect devices, if used, shall likewise comply with national and local codes.

DANGER

The fryer MUST be connected to the gas supply specified on the rating and serial number

plate located on the back of the fryer door.

DANGER

If gas odors are detected, the gas supply MUST be shut off at the main shut-off valve. The

local gas company or FASC should be contacted immediately to rectify the problem.

The gas supply (service) line must be the same size or greater than the fryer inlet line. This fryer is

equipped with a ¾" (22 mm) male inlet. The gas supply line must be sized to accommodate all the

gas-fired equipment that may be connected to that gas supply. Consult your contractor, gas

company, supplier, or other knowledgeable authorities.

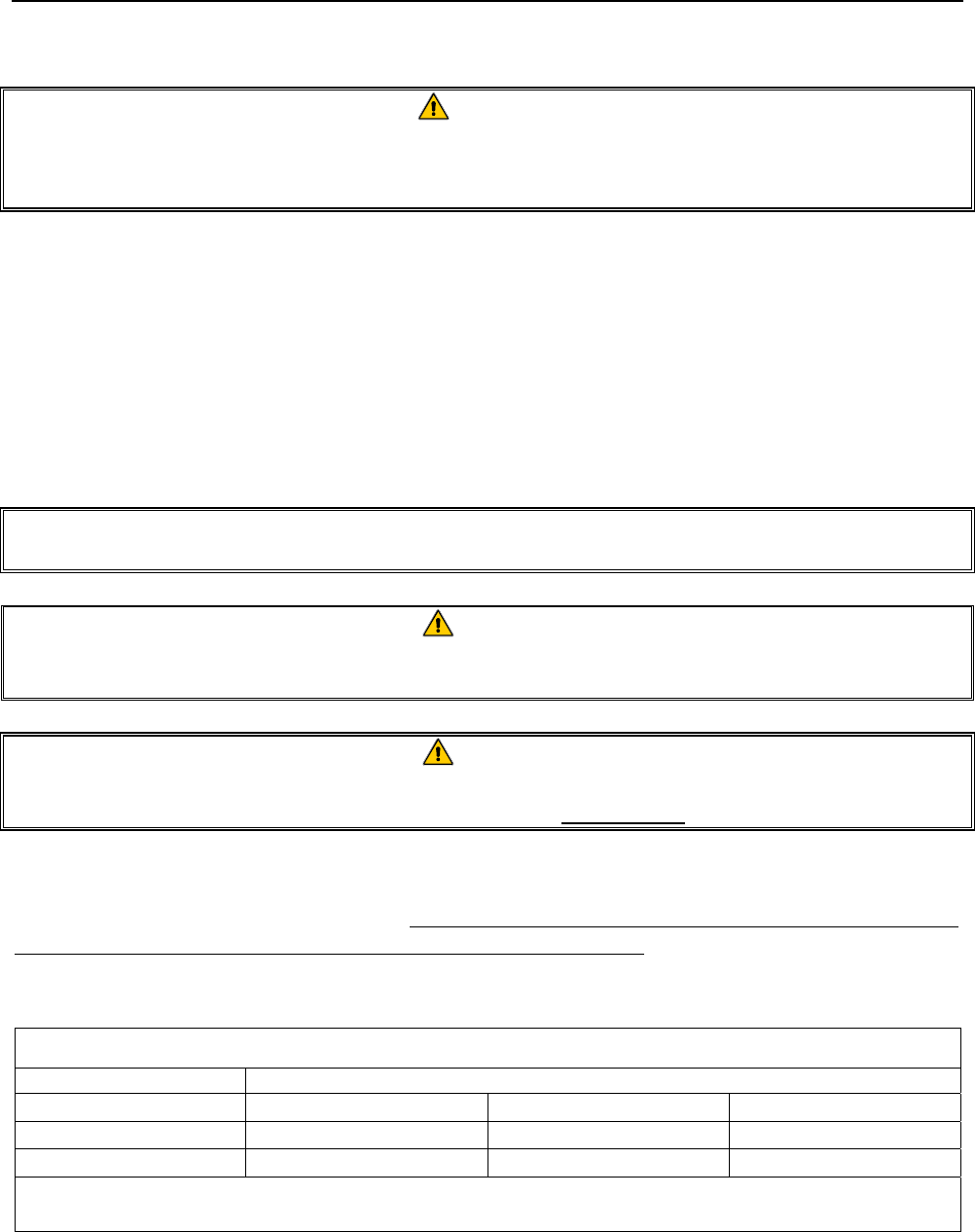

Recommended Gas Supply Line Sizes

Gas Types Number of Fryers

1 2 to 3 4 or more (*)

Natural Gas

¾" (22 mm)

1" (28 mm) 1¼" (35 mm)

Propane (LP) Gas ½" (15 mm)

¾" (22 mm)

1" (28 mm)

(*) When exceeding 18 feet for a configuration of more than four fryers, it is necessary to provide

a 1¼" (35 mm) rigid gas connection.