Flushing

14 309535L

Flushing

There are times when you only want to flush the fluid

manifold, such as:

• breaks in spraying

• overnight shutdown

• end of potlife

In this manual, that procedure is referred to as Fluid

Manifold Flushing. You can flush the fluid manifold by

connecting either a:

• solvent pump to the fluid manifold or

• hose and solvent siphon tube to pump A

Other times, you need to flush the entire system:

• first time material is loaded into equipment*

• color change

•servicing

• shutting down equipment for more than 24 hours

• putting equipment into storage

* Some Full System Flushing steps are not necessary for

initial flushing, as no material has been loaded into the sys-

tem yet.

To flush the entire system, you first follow the Fluid

Manifold Flushing procedure, at right, then the Full

System Flushing procedure, page 16.

Fluid Manifold Flushing

Using Solvent Pump

WARNING

Read warnings, pages 5-6.

• If your system includes heaters and heated

hose, turn them off and allow to cool before

flushing. Do not turn on heaters until fluid

lines are clear of solvent.

• Use the lowest possible pressure when flush-

ing to avoid splashing.

• Before color change or shutdown for storage,

flush at a higher flow rate and for a longer

time.

• To only flush fluid manifold, see following pro-

cedure.

• A circulation setting is available. Consult your

distributor. Refer to page 25.

Model 248842 Only: Follow the flushing procedure

in the Remote Manifold manual 310797.

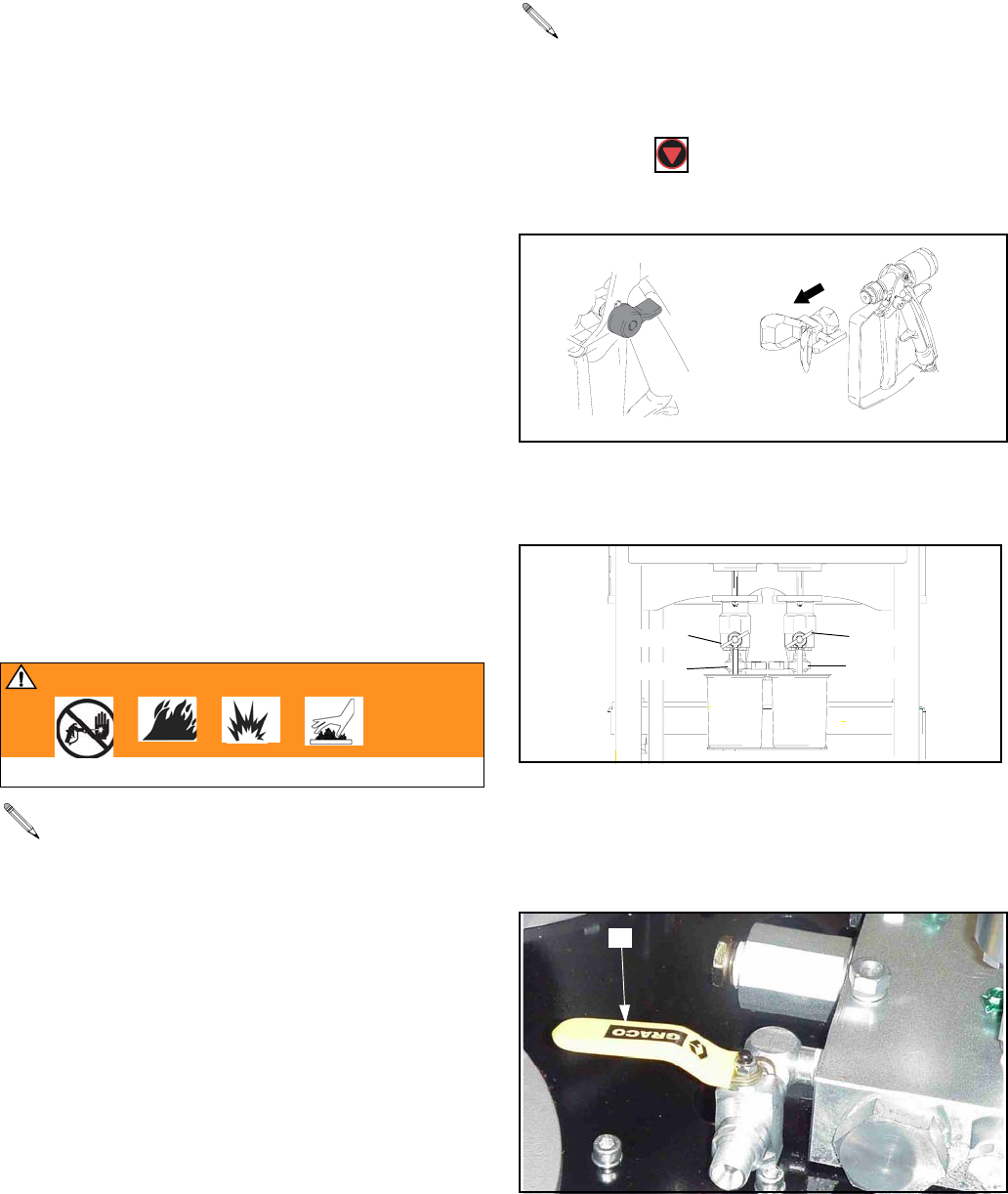

1. Press Stop to turn off proportioner. Follow Pres-

sure Relief Procedure, page 10. Engage trigger

lock. Remove spray tip.

2. Close sampling valves and fluid shutoff valves A and

B.

3. Connect a shutoff valve (V) to the fluid manifold inlet

on the A side as shown below (valve shown closed).

Connect solvent pump line to the shutoff valve. Turn

on solvent pump and open solvent shutoff valve.

TI1948A

ti1949a

AB

Close

Close

Close

Close

V