20

INSTALLATION

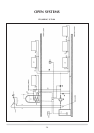

1.1 The supply pipe from the cooker is 3/4” BSP threaded male.

An isolating gas valve must be fitted adjacent to the cooker and

the gas installation pipe work must be installed, inspected,

tested for soundness and purged in accordance with BS 6891

Nominal inlet gas pressure 20mbar

Maximum gas pressure 25 mbar

Minimum gas pressure

with both burners running 17 mbar

2.1 To evacuate the products of combustion safely and

thoroughly, the cooker must have an efficient flue system.

Reference should also be made to BS 5440 Part 1 & 2 if

further information is required on conventional chimneys.

2.2 This unit is designed to work on a conventional flue system

with a draught of 0.05” +/- 0.02” W.G (12.45 +/- 4.98 Pa or

0.124 +/- 0.498 mbar).

2.3 The chimney should rise as vertically as possible and terminate

at a point not subject to down draughts or wind eddies.

2.4 Brick and masonry chimneys must be lined with a moisture

and acid resistant liner of the same diameter as the boiler

flue outlet.

2.5 A factory made insulated chimney complying with BS 4543

Part 3 may be considered as an alternative to a structural

chimney both for new and existing buildings.

2.6 The in-built flue gas resistance of the appliance is such that it

allows the boiler to operate reliably over the wide range of

chimney draughts encountered from typical domestic

chimneys. The use of a flexible stainless steel liner is a convenient

method of lining an existing chimney and this should be back

filled with ‘vermiculite’ or similar insulating material to retain

heat. A flexible liner should also be used in chimneys fitted

with large diameter clay liners to reduce the flue bore and

improve the thermal insulation.

2.7 The use of a draught stabiliser should not be necessary nor it

desirable since it allows flue noises to be emitted into the

room.

Notes:

1. In view of the appliances high terminal efficiency it is

important that a liner is fitted, otherwise condensation

problems could result.

2.Before fitting a liner, the chimneymust be thoroughly

cleaned free from all traces of soot and scale.

1. GAS SUPPLY

3.1 There are four basic chimney/vent systems that can be used

with gas fired appliances.

These are:-

Twin Wall Gas Vent.

3.2 A metal twin wall flue system incorporating an air gap of

between 6 mm and 20 mm constructed in either all

aluminium for external use or aluminium inner and

galvanised or stainless steel outer skin recommended for

internal use only. Such products shall be certified to BS 715.

Stainless Steel Lined Prefabricated Chimneys.

3.3 These chimney systems consist of two skins of stainless steel

or a combination of stainless steel and galvanised steel

incorporating high quality insulating materials. Depending upon

the materials of combustion, these products can be used internally

and externally. Such products shall be certified to BS 4543.

Ceramic or Concrete Lined Prefabricated Chimney.

3.4 Similarly, constructed to the previous category except that

the inner liner is fabricated with either lightweight fireproof

concrete or ceramic material. These products shall be

certified by the British Board Agreement.

Concrete Block/Masonry Chimneys.

3.5 These can be divided into three different categories:-

(i) Conventional brick or masonry construction with either

clay to BS 1181 or refractory concrete flue liner manufactured

from a kiln burnt aggregate and high alumina cement.

(ii) Prefabricated chimney block systems

(iii) Gas Flue blocks.

3.6 Category (i) is the conventional chimney and in the majority

of installations where used with a gas appliance it will be

necessary to utilise a stainless steel flexible liner. The second

category (ii), prefabricated block chimney systems are designed to

accommodate quite a range of heating appliances, gas

appliances included. In some cases they may need to be

lined with a flexible liner. The appliance manufacturer and

chimney manufacturer should be consulted for guidance.

The final category (iii), gas flue blocks consists of a narrow

rectangular flue way within a building block normally used as

part of the internal or external construction of the house.The

flue way is usually very narrow, and the systems are often

linked with twin wall gas vent to which they are “adapted” in

the roof space, after which the gas vent completes the chimney

run through termination. Such systems should be carefully

inspected for soundness before being used. If they are

incorrectly constructed they can contribute to operational

difficulties and in particular condensation within the chimney

system as a whole. If any doubts should arise as to the

condition of such chimney systems they should be carefully

checked and possibly replaced with a new flue system.

2. FLUE & CHIMNEY REQUIREMENTS

3. TYPES OF CHIMNEY AND FLUE SYSTEMS