42

4. Removal and Replacement of Evaporator

NOTICE

• Always install a new drier every time the sealed refrigeration system is opened.

• Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

ow.

• When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

1) Move the control switch to the "DRAIN" position and drain all of the water from the

evaporator.

2) After the water has stopped draining, move the control switch to the "OFF" position,

then turn off the power supply. Remove the front and top panels, then move the power

switch to the "OFF" position.

3) Remove the apron panel, then remove the left side panel.

4) Recover the refrigerant and store it in an approved container.

5) Remove the front cover of the storage bin. Remove spout B, then remove spout A.

See Fig. 2.

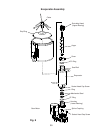

6) Remove the allen head cap screws securing the extruding head. Using the cutter, lift out

the auger assembly.

7) Remove the evaporator bracket and disconnect the water hoses.

8) Disconnect the inlet and outlet tubing.

9) Remove the allen head cap screws securing the evaporator to the lower housing.

10) Lift off the evaporator.

11) Inspect the mechanical seal and O-ring prior to installing the new evaporator. The

mechanical seal consists of two parts. One moves along with the auger, and the other

is xed on the lower housing. NOTICE! If the contact surfaces of these two parts

are worn, cracked, or scratched, the mechanical seal may cause water leaks and

should be replaced. Instructions for removing the mechanical seal and lower housing

are located later in this procedure.

12) Make sure the lower mechanical seal is in place, then place the new evaporator in

position. Secure the evaporator to the lower housing using the allen head cap screws.

13) Remove the drier, then place the new drier in position.

14) Braze all ttings while purging with nitrogen gas owing at a pressure of 3 to 4 PSIG.