Rev. 0010

5

FINISHING TOUCHES

(PERFORM AFTER PLUMBING AND ELECTRICAL)

ACCESS PANELS

All electrical and drain access panels are clearly labeled

on the deck of the stand. .

INSTALLING SPLASHGUARD

After merchandisers have been leveled and joined and all

electrical and plumbing work has been completed, install

the splashguards. After adjusting brackets flush with the

floor, position splashguard up behind the front panel

first—then position the lower portion over the previously

adjusted brackets. Splashguards may be sealed to the floor

using a vinyl cove base trim. The size of trim needed will

depend on how much the floor is out of level.

NOTE: The splashguard must be removable to access compo-

nents behind it.

1. Remove all dirt and wax (etc.) from the area of the

splashguard to ensure a secure adhesion.

2. Apply a good contact cement to the trim, allowing

for proper dry-time.

3. Install trim to the splashguard so that it is flush with

floor.

Do not seal trim to floor!

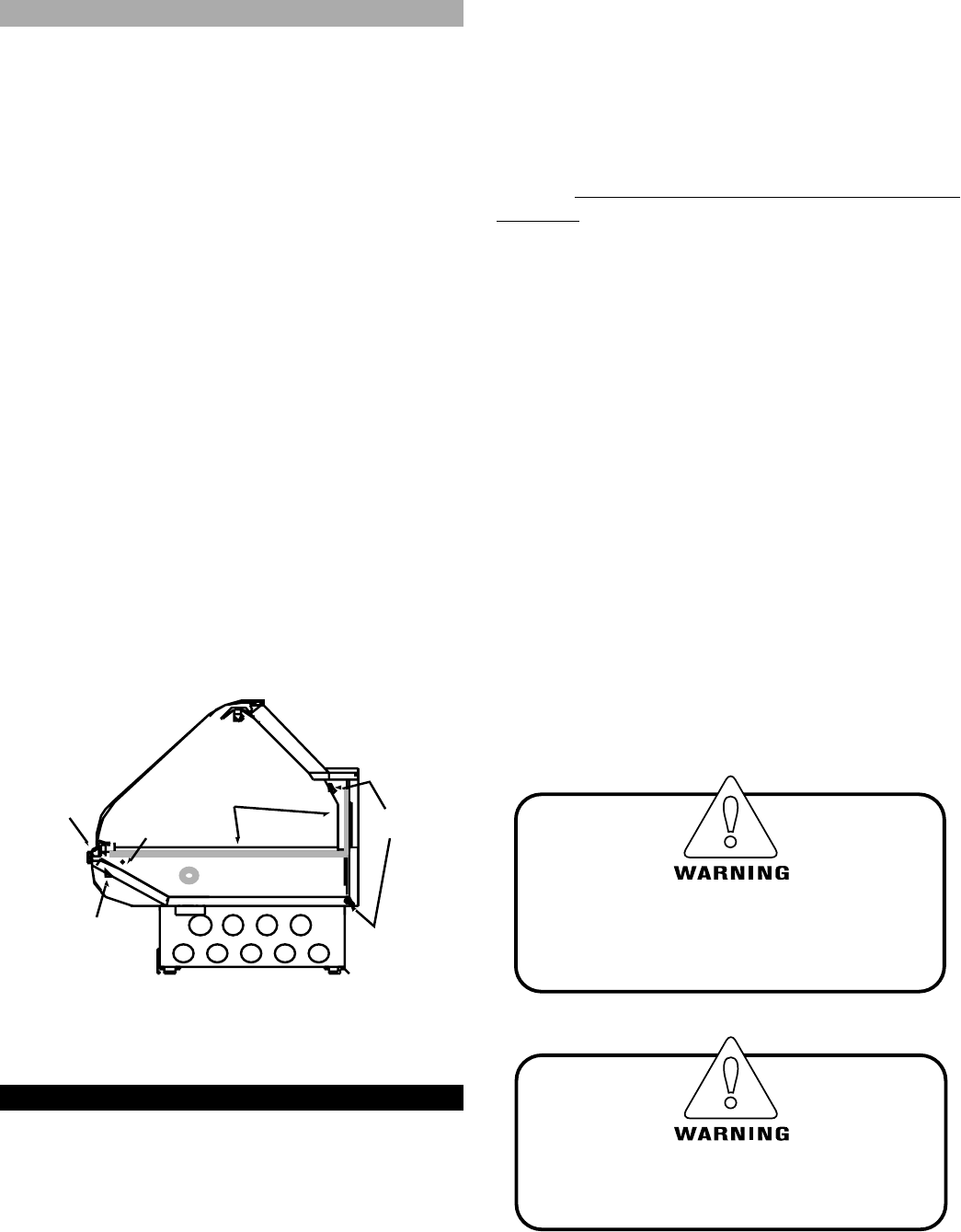

BOLT AND SEALANT LOCATIONS

CAMLOCK

&

SEALANT

LOC ATI O NS

CAMLOCK

LOCATION

(BOLT BRACKET

IN WEDGES)

APPLY SEALANT

TO SHADED AREA

JOINT BACKER

LOCATION CAMLOCK

LOCATIONS

SEALAROUND PIPING

ACCESS HOLES

BOLT INSIDE

WEDGES

Plumbing

WASTE OUTLET

The waste outlet is located under the hot wells and can

be accessed from the back.

Drain is 1" copper. A stub is provided for extending to

sink. Drain must be run in a material that will withstand a

150°F (66°C) (or more) temperature, such as copper.

WATER SUPPLY CONNECTION

The well fill water hose on these models will need to be

connected to a water supply. The water connection is 1/

2", and consists of a hand gate valve. If the water pressure

exceeds 45 psi, a water pressure regulating valve should

be installed in the supply line, and set at 30-35 psi outlet

pressure. The pressure regulating valve is not supplied by

Hussmann.

For a quick preheat time, the customer may want to

pipe in hot water. If hot water is piped into the case, tem-

perature of water supply must not exceed 150°F(66°C).

In areas where water contains a heavy mineral content, it

may be a good idea to install a cartridge-type water filtra-

tion system.

Proper water depth is 1". These cases come equipped

with an auto-fill system designed to slowly feed in water

to maintain the proper water level, and prevent damage

incurred when cold water is fed too fast into a hot well.

In common well configurations, the water level is regu-

lated by adjusting the probe on the inside of the well. In

multi-well configurations, use the sliding plate at the rear

of the case to adjust the float level. The water level is main-

tained in direct relation to the vertical position of the

plate. The water feeds in slowly, so it is not necessary to

shut water off during cleaning. It is advisable to allow a

number of hours for the system to refill. If necessary, the

case may also be filled manually, with the use of buckets.

NOTE: Some local codes may require the installation of check

valves in the water supply.

Do not plumb below the sliding plate

on the side of the hot well!

Doing so may interfere with the

ability to adjust the water within the well!

Damage may occur if cold water is fed

into a preheated hot well too quickly!

Installation cont.