Quest Juice Training Manual

© 2004, IMI Cornelius Inc. - 3 - Publication Number: TP00968

SYSTEM DETAILS

WATER

Water Quality

Water quality has an affect on juice dispensing systems.

• odor

• taste

• clarity/foaming

Water filtration is recommended to assure the best beverage taste.

Water Flow

Inlet water pressure should be regulated to 45 to 50 psi max. (3.1 bar) to prevent damage to pump tub-

ing. Minimum flowing pressure must be 20psi.

Flow Rates

Adequate water flow is necessary and must be at least 3.0 ounces per second (89ml) at the inlet to the

unit.

CONCENTRATE

• Concentrate should be stored frozen and put into a cooler 72 hours before use. Rapid cooling, such

as in a sink of hot water, adversely affects flavor and leads to service calls.

• Proper loading of concentrate is important. Improper loading is a major source of service calls.

• Concentrates vary in viscosity and mixing valves must be adjusted accordingly.

• When changing concentrate, be sure to check the concentrate container O-ring for damage. It should

be clean and wet with concentrate or a food grade lubricant.

• Shake or stir pulp based concentrates.

• When changing flavors, be sure to flush the system and reset the pump.

• Nozzles should be cleaned daily. Remove the nozzles and wash in warm soap solution. Rinse with

clean water, lubricate the O-ring, and replace nozzle.

• Flushing daily and sanitizing weekly is recommended.

SETTING THE BRIX

• A refractometer must be used to measure the post-mix brix.

• Ratio adjustment can be set with a concentrate separator and ratio cup, see Brixing Procedure.

• Ratios are sometimes set by taste but this is not recommended.

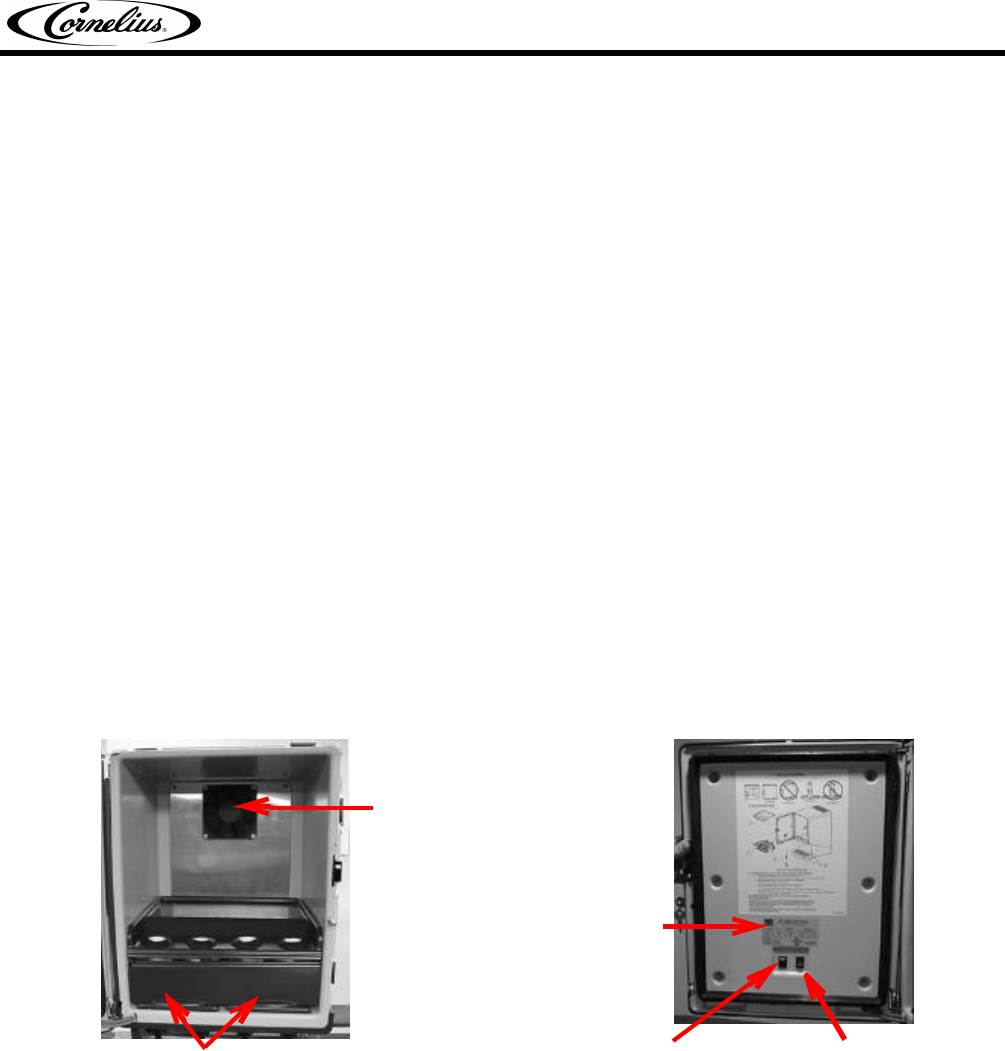

Cabinet

Cooling Fan

Serial Decal

Lighted Merchandiser

ON/OFF

Left and Right Pump Platforms

Platform Pump

ON/OFF