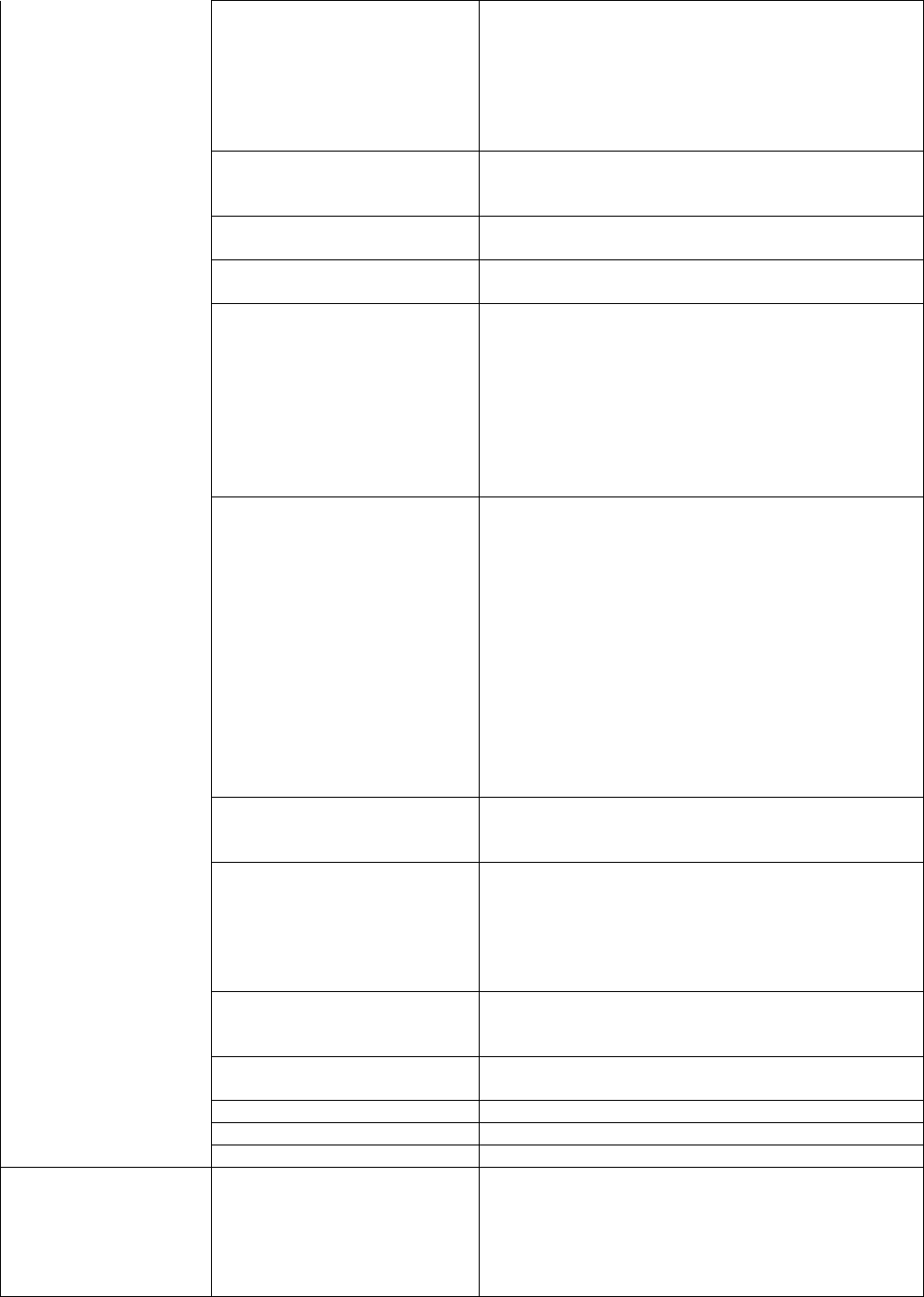

Impinger I -–1000 Series Service Manual - International 33

Intermittent heating As Follows Both the main fan motor and burner blower motor

are equipped with thermal protection and will cease

to operate if overheating occurs. This can cause

the units to cycle on and off intermittently. This may

be caused by improper ventilation. Also most of the

problems listed under "oven will not heat" can

cause intermittent failure.

Voltage Supply Check incoming voltage supply at line 1 to neutral.

There should be a voltage reading of 120 VAC. If

not present, check breakers.

3 Amp Fuse This conveyor fuse is located on the front panel.

Replace if defective.

Fuse Holder Conveyor Switch Check and/or Replace. Same procedure as for fan

switch.

D. C. Motor Control Board Check for 120 VAC input to D. C. control board

across L1 and L2. Check the 3 amp fuse on the D.

C control board. Check for D.C. voltage at terminal

F1 and F2. Voltage should be 100 VDC ± 10

steady. If this voltage is not present, replace D. C.

control board. Check for D. C. voltage output to the

motor across terminals A1 and A2 (this voltage

should be approx. 125 VDC at maximum conveyor

motor speed).

Speed Control Potentiometer This is a 0 to 400 ohm or 0 to 500 ohm, 10-turn

potentiometer. WITH POWER OFF: remove the

red, white, and black leads from terminals S1, S2,

S3. With a digital multimeter, check the ohm

reading across the red to black leads. This ohm

reading should be a steady 400-ohm, or 500-ohm,

through the entire 10-turn rotation of the

potentiometer. Red to white, should be 0-400 or 0-

500 ohms as the pot. is rotated. Check for shorts or

opens or unsteady, ohm reading, if potentiometer is

defective, replace. If the potentiometer checks OK,

and

there is no output at terminals A1 and A2, replace

the D.C. control board.

Reversing Switch If there is D. C. voltage output from the motor

control board, but the conveyor drive motor is not

running, check the D.P.D.T. reversing switch.

Conveyor will not run

(S/N 100-4389)

Conveyor Drive Motor Check the conveyor drive sprocket for tightness.

Disconnect the motor, check the red and black

motor leads for opens, shorts or grounds. Check

the brushes for excessive or abnormal wear.

Replace as needed. Reconnect motor. Test for

operation. If motor does not run, replace.

Voltage Supply Check incoming voltage supply at line 1 to neutral.

There should be a voltage reading of 120 VAC. If

not present, check breakers.

3 Amp Fuse This conveyor fuse is located on the front panel.

Replace if defective.

Fuseholder Check and/or Replace

Fan Switch See procedure for checking on page 26.

Conveyor will not run

(S/N 4390 to Q14974

1000 Series

S/N 4390-Q14790

1200 Series)

Conveyor Switch Same procedure as for fan switch.

NOTE: (Dual Belt Ovens) Dual belt ovens utilize 2 complete independent

conveyor drive systems. The trouble shooting

procedures are the same as single belt ovens,

except that the dual belt ovens use one each of the

following: one "A" DC. control board and one "B" D.

C. control board.