12P/N60250September28,2012

III. VENTILATION SYSTEM

B. Recommendations

NOTE THAT THE HOOD DIMENSIONS SHOWN IN

FIGURE 2-5 ARE RECOMMENDATIONS ONLY.

LOCAL, NATIONAL AND INTERNATIONAL CODES

MUST BE FOLLOWED WHEN INSTALLING THE

VENTILATION SYSTEM. ANY APPLICABLE CODES

SUPERSEDE THE RECOMMENDATIONS SHOWN IN THIS

MANUAL. IN AUSTRALIA COMPLIANCE TO REGULATIONS

AS5601/AG601 IS MANDATORY.

The rate of air ow exhausted through the ventilation system

may vary depending on the oven conguration and hood de-

sign. Consult the hood manufacturer or ventilation engineer

for these specications.

To avoid a negative pressure condition in the kitchen area,

return air must be brought back to replenish the air that was

exhausted. A negative pressure in the kitchen can cause

heat- related problems to the oven components as if there

were no ventilation at all. The best method of supplying return

air is through the heating, ventilation and air conditioning

(HVAC) system. Through the HVAC system, the air can be

temperature-controlled for summer and winter. Return air can

also be brought in directly from outside the building, but detri-

mental effects can result from extreme seasonal hot and cold

temperatures from the outdoors.

NOTE: Return air from the mechanically driven system must

not blow at the opening of the baking chamber. Poor

oven baking performance will result.

C. Other ventilation concerns

• Special locations, conditions, or problems may require the

services of a ventilation engineer or specialist.

• Inadequate ventilation can inhibit oven performance.

• It is recommended that the ventilation system and duct

work be checked at prevailing intervals as specied by the

hood manufacturer and/or HVAC engineer or specialist.

A. Requirements

CAUTION: Gas oven installations REQUIRE a mechanically

driven ventilation system with electrical exhaust

air sensing control.

A mechanically driven ventilation system is STRONGLY

RECOMMENDED for electric oven installations.

PROPER VENTILATION OF THE OVEN IS THE RESPON-

SIBILITY OF THE OWNER.

IMPORTANT

Where national or local codes re-

quire the installation of re sup-

pression equipment or other

supplementary equipment, DO NOT

mount the

equipment directly to the oven.

MOUNTING SUCH EQUIPMENT ON

THE OVEN MAY:

• VOID AGENCY CERTIFICATIONS

• RESTRICT SERVICE ACCESS

• LEAD TO INCREASED SERVICE

EXPENSES FOR THE OWNER

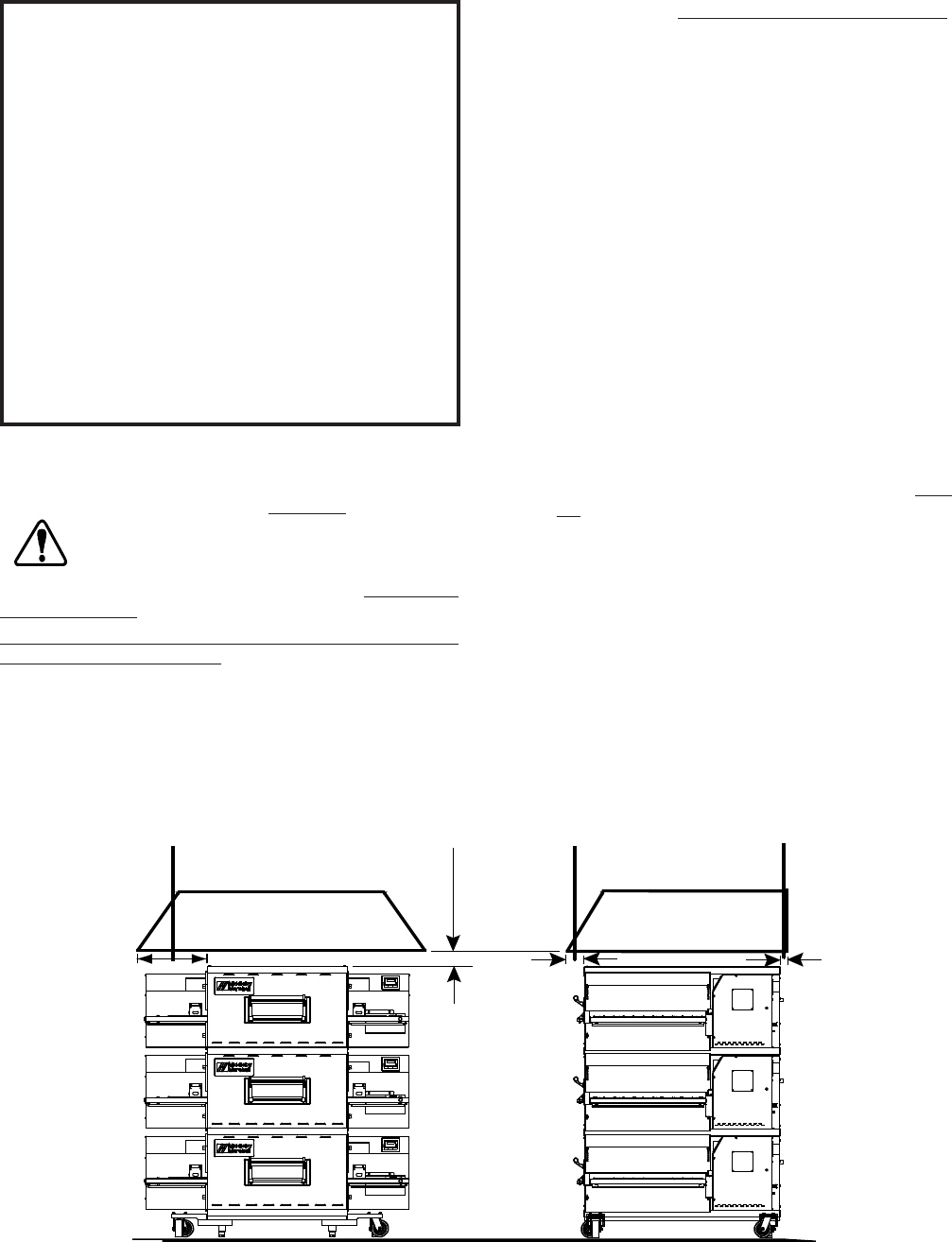

Figure 2-5. Ventilation System

18″ (458mm)

minimum

(Typical - both

ends of oven)

2″ (51mm)

minimum

3″ (76mm)

minimum

8″ (203mm)

minimum