19

SECTION 2

INSTALLATION

VI. ELECTRIC SUPPLY FOR GAS HEATED OVENS

Electric supply for all gas heated ovens is 208-240 volts

AC single phase. Each oven requires a separate 15 amp

service. Connection is made as shown in Figures 2-8 &

2-12. A separate ground wire must also be supplied.

CAUTION: Before connecting incoming power to oven,

a voltage reading of each leg to neutral must be made.

These readings should not normally exceed 120 volts

each.

If one of the incoming legs reads over 130 volts, this

indicates the supply voltage has a high leg.

Export ovens are supplied with a stepdown transformer

for the 110V control circuit.

Call your local electrician or electrical power supply

company and have them remove the high leg from the

electrical supply line for the oven.

Connecting a high leg to the black lead of the oven will

severely damage many of the electrical components in

the oven.

CONNECTING A HIGH LEG TO THE BLACK WIRE

VOIDS ALL OVEN WARRANTIES.

NOTE:

When the oven is installed it must be electrically

grounded in accordance with local codes, or in the

absence of local codes. ANSI/NFPA - Latest edition.

CAUTION

IT IS REQUIRED THAT THE OVEN BE

PLACED UNDER A VENTILATION HOOD

FOR ADEQUATE AIR SUPPLY

AND VENTILATION

WARNING

OVEN MUST BE KEPT CLEAR

OF COMBUSTIBLES

AT ALL TIMES.

CAUTION:

The power burner will not operate and gas will not flow through the burner

without electric power. No attempt should be made to operate the oven during

power failure.This oven is to be operated only on the type of gas as shown on

the specification data plate.

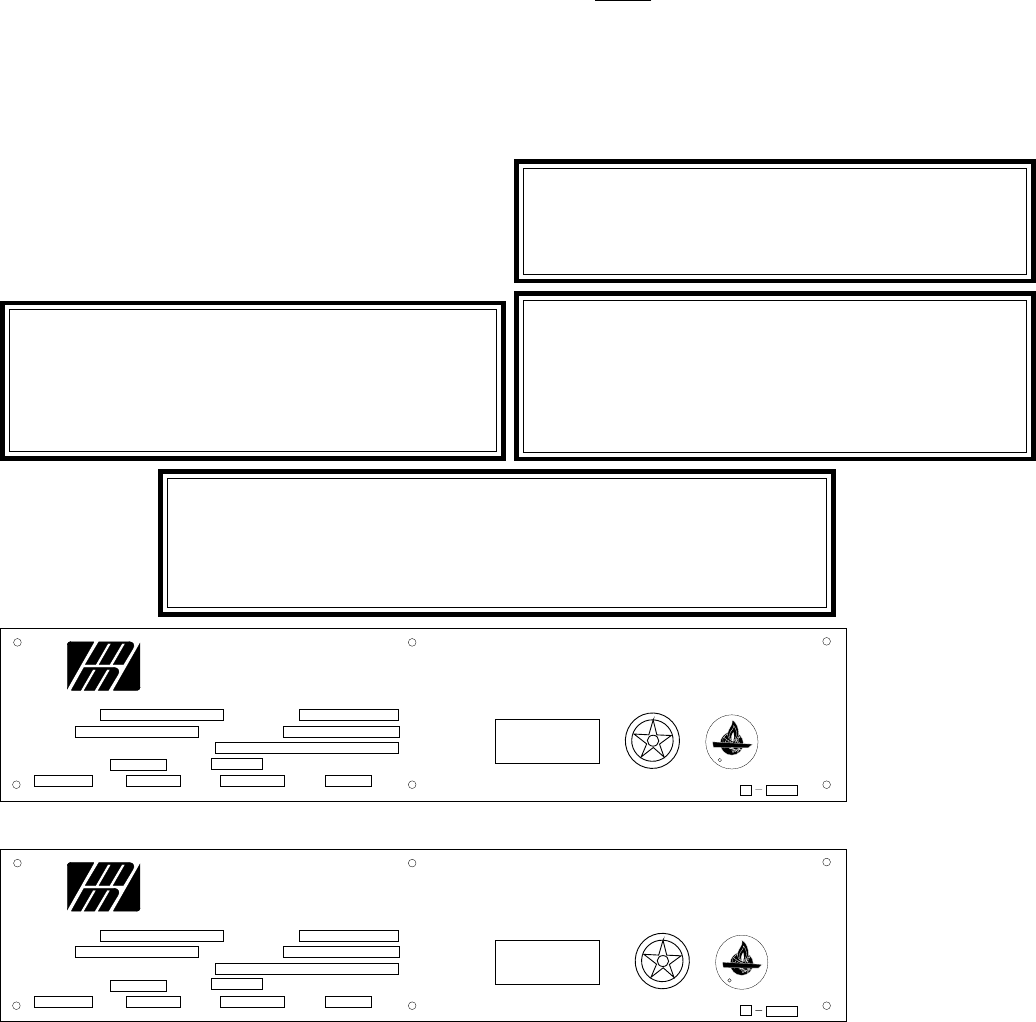

A MIDDLEBY COMPANY

Middleby

Marshall

MODEL NO.

ID NO.

INPUT BTU PER HOUR MAXIMUM

MAN. PRESS.

"INTENDED FOR OTHER THAN HOUSEHOLD USE"

FOR INSTALLATION UNDER VENTILATING HOOD ONLY

SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOORS ADJACENT

TO COMBUSTIBLE AND NONCOMBUSTIBLE WALLS WITH THE FOLLOW-

ING MINIMUM CLEARANCES: ZERO INCHES TO RIGHT SIDE WALL,

EIGHTEEN INCHES TO LEFT SIDE WALL, SIX INCHES TO BACK WALL.

SERIAL NO.

TYPE OF GAS

IN.W.C.

WIRE WITH GROUND

VAC AMPS AMPS HZ

MANUFACTURED UNDER U.S. PATENT NUMBERS 3,844,213 AND 4,154,861

ELGIN, ILLINOIS, 60120, U.S.A. COMMERCIAL OVEN ANS Z 83.12

ACCEPTED FOR USE

CITY OF NEW YORK

DEPARTMENT OF BUILDINGS

MEA 309-83-E

DATA PLATE FOR OVENS WITH THE MACHINERY/DRIVE COMPARTMENT LOCATED AT THE LEFT END OF OVEN

A MIDDLEBY COMPANY

Middleby

Marshall

MODEL NO.

ID NO.

INPUT BTU PER HOUR MAXIMUM

MAN. PRESS.

"INTENDED FOR OTHER THAN HOUSEHOLD USE"

FOR INSTALLATION UNDER VENTILATING HOOD ONLY

SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOORS ADJACENT

TO COMBUSTIBLE AND NONCOMBUSTIBLE WALLS WITH THE FOLLOW-

ING MINIMUM CLEARANCES: ZERO INCHES TO LEFT SIDE WALL,

EIGHTEEN INCHES TO RIGHT SIDE WALL, SIX INCHES TO BACK WALL.

SERIAL NO.

TYPE OF GAS

IN.W.C.

WIRE WITH GROUND

VAC AMPS AMPS HZ

MANUFACTURED UNDER U.S. PATENT NUMBERS 3,844,213 AND 4,154,861

ELGIN, ILLINOIS, 60120, U.S.A. COMMERCIAL OVEN ANS Z 83.12

ACCEPTED FOR USE

CITY OF NEW YORK

DEPARTMENT OF BUILDINGS

MEA 309-83-E

DATA PLATE FOR OVENS WITH THE MACHINERY/DRIVE COMPARTMENT LOCATED AT THE RIGHT END OF OVEN

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

A

M

E

R

I

C

A

N

G

S

A

A

S

S

O

C

I

A

T

I

O

N

CANADIAN GAS ASSOCIATION

APPROVED

R

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

A

M

E

R

I

C

A

N

G

S

A

A

S

S

O

C

I

A

T

I

O

N

CANADIAN GAS ASSOCIATION

APPROVED

R

Figure 2-11.

Oven Specifi-

cation Data

Plate Refer-

ence

Connect one 208-240V supply leg to the black wire and

the other 208-240V supply leg to the red wire. The supply

neutral should connect to the white oven wire and supply

ground should connect to the oven ground screw located

in the main junction box.

VII. ELECTRICAL CONNECTION

INFORMATION FOR ALL OVENS.

Check the oven data plate before making any electrical

connections. Connections must agree with data on oven

data plate (Refer below to Figure 2-11).

NOTE: In Canada with C22.1,Part 1 and/or local code.

A fused disconnect switch or circuit breaker (not fur-

nished) MUST be installed in the electrical supply line

FOR EACH OVEN. A lockout/tagout electrical shutoff

must be installed for each oven, refer to Figure 2-9. The

service connection must meet all national and local

electrical code requirements. All connections are made

at one common connection at the back of each control

box.