Alarm Number Explanation:

The alarms are given in individual bits and are reflected in the alarm number. The alarm number is only

used to drive a pop-up message and will probably not be very useful to you. If you decide to use the

alarm number instead of reading the individual alarm bits then the related values are shown below:

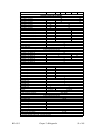

D1876 Value Alarm Description

0= NO ALARM

1= HOPPER 1 Out of Material 1

2= HOPPER 2 Out of Material 2

3= HOPPER 3 Out of Material 3

4= HOPPER 4 Out of Material 4

5= HOPPER 5 Out of Material 5

6= HOPPER 6 Out of Material 6

7= POWER INTERRUPTION while metering a Batch

8= PLC BATTER LOW Check PLC and Configure the Blender

9= MAX HOPPER WEIGHT EXCEEDED. CHECK BATCH SIZE

10= CALIBRATION ERROR. Clean out weigh hopper and check calibration

12= HOPPER 1 Low Level

13= HOPPER 2 Low Level

14= HOPPER 3 Low Level

15= HOPPER 4 Low Level

16= HOPPER 5 Low Level

17= HOPPER 6 Low Level

FIXED DECIMAL EXPLANATION

All weight values and recipe values use fixed decimal. This must be taken into consideration when

writing or reading values. If you see “xxx.xxx” above this means the data is in fixed decimal and must be

scaled when reading or writing. A decimal is shown next to each item to represent the format.

BF1-615.3 Chapter 7: 6BAppendix 99 of 101