11

A. Prepare detergent water by mixing 2 oz. of

Palmolive detergent or equivalent in 2 gallons of

90° to 110°F (32° to 43°C) water. Place all parts

in detergent solution and clean with provided

brushes. Rinse all parts with clean 90° to 110°F

(32° to 43°C) water.

B. Wash the hopper and freezing cylinder with the

90° to 110°F (32° to 43°C) detergent water and

brushes provided (Refer to Figure 3-9).

C. Clean the rear seal surfaces from the inside of the

freezing cylinder with the 90° to 110°F (32° to

43°C) detergent water.

D. Clean the drip tray and insert with a soap solution.

Rinse with clean hot water.

3.10 SANITIZE FREEZER AND FREEZER

PARTS

A. Use a sanitizing solution mixed according to

manufacturer's instructions to provide 100 parts

per million strength solution. Mix sanitizer in

quantities of no less than 2 gallons (7.5 liters) of

120°F water. Allow the sanitizer to contact the

surfaces to be sanitized for 5 minutes. Any sanitizer

must be used only in accordance with the

manufacturer's instructions.

B. Place all parts in the sanitizing solution, then

remove and let air dry.

C. Using this sanitizing solution and the large barrel

brush provided, sanitize the rear of the barrel by

dipping the brush in the sanitizing solution and

brushing the rear of the barrel.

3.11 ASSEMBLY OF FREEZER

To assemble the freezer parts, refer to the following steps:

NOTE

Petrol Gel sanitary lubricant or equivalent must be

used when lubrication of parts is specified.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that lu-

bricants used on food processing equipment be cer-

tified for this use. Use lubricants only in accordance

with the manufacturer’s instructions.

A. Assemble all o-rings onto parts dry, without

lubrication. Then apply a thin film of sanitary

lubrication to exposed surfaces of the o-rings.

Apply a thin film of sanitary lubricant to metal part

of rear seal. Also apply a thin film of sanitary

lubricant inside and outside of the front auger

support bushing.

B. Assemble the rear seal onto the auger with the

large end to the rear. Be sure the o-ring is in place

before installing the rear seal.

C. Lubricate the auger drive (rear) with a small

amount of white socket lubricant. A small container

of socket lubricant is shipped with the freezer.

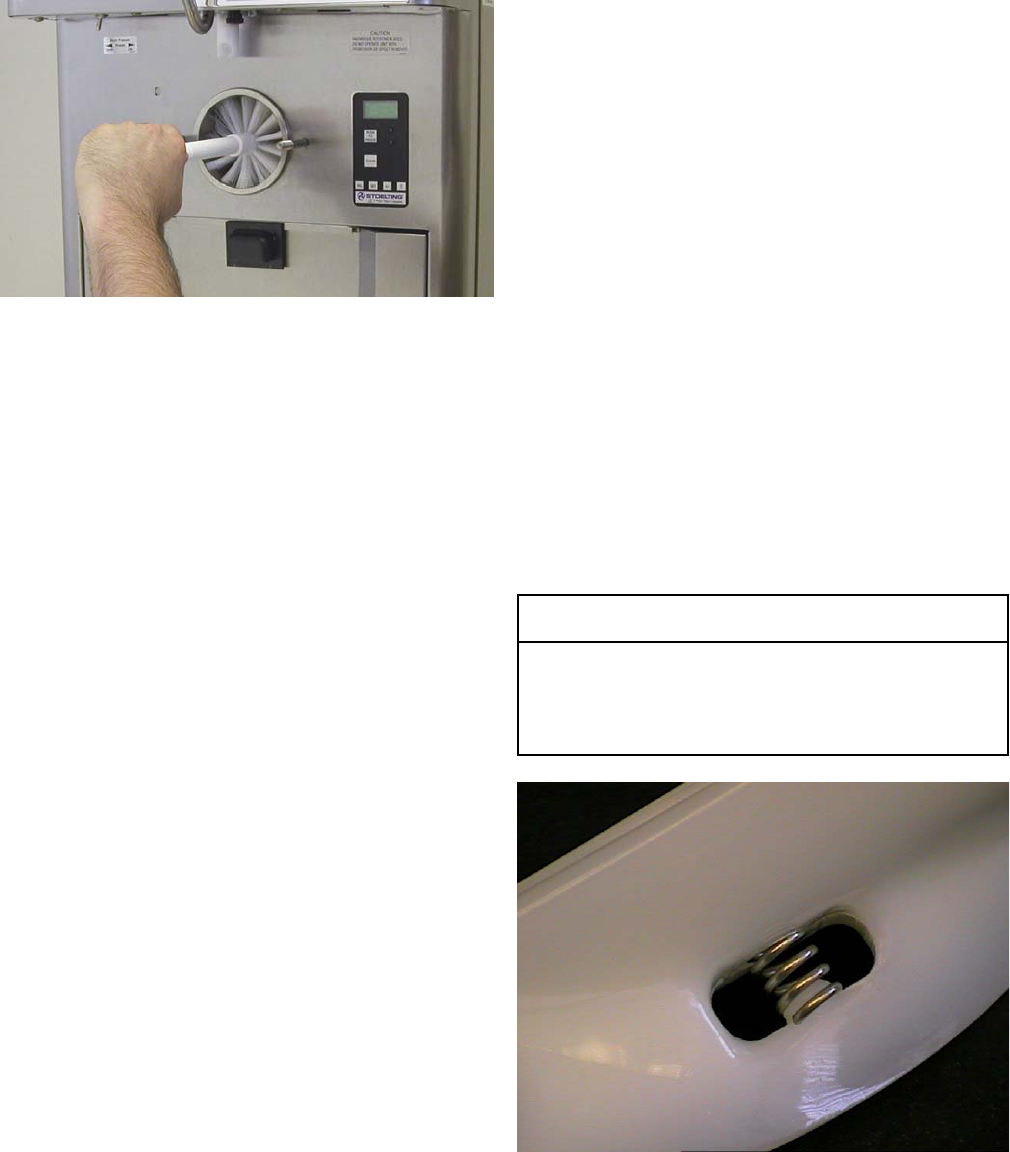

D. Screw the springs onto the studs in plastic flights.

Springs must be screwed into the flights completely

to provide proper compression (Fig. 3-10).

CAUTION

Do not place the mix inlet regulator into the hopper

before installing the auger. Attempting to install the

auger with the mix inlet regulator in place will dam-

age the mix inlet regulator.

E. Install the two plastic flights onto rear of the auger

and insert part way into freezer barrel.

F. Install the remaining plastic flights, push the auger

into the freezer barrel and rotate slowly until the

auger engages the drive shaft.

G. Install the bushing and auger support into the front

of the auger with one leg of the support pointing

straight up.

Figure 3-10 Cleaning Freezer Barrel

Figure 3-11 Auger Springs