12

Operating Procedures

Model 104

Section 6 Operating Procedures

The Model 104 is a small 3 quart (2.9 liter) capacity ice

cream freezer. It has been designed to produce a rich

tasting, nominal overrun ice cream pr oduct that can b e

drawn off and placed in a hardening cabinet or flash

freezer. Overrun can be varied depending on mix

formulation, amount of pre--charge, and finished

product temperature.

We begin our instructions at the point where we find

the parts disassembled and laid out to air dry from the

previous brush cleaning.

The following procedures will show you how to

assemble the parts into the freezer, s anitize them, and

prime the freezer with fresh mix to prepare the first

batch.

If you are disassembling the machine for the f irst time

or need information to get to this starting point in our

instructions, turn to page 19, “Disassembly”, and start

there.

Assembly

Step 1

MAKE SURE CONTROL SWITCH IS IN THE

OFF POSITION. Failure to do so may cause personal

injury or component damage.

Figure 5

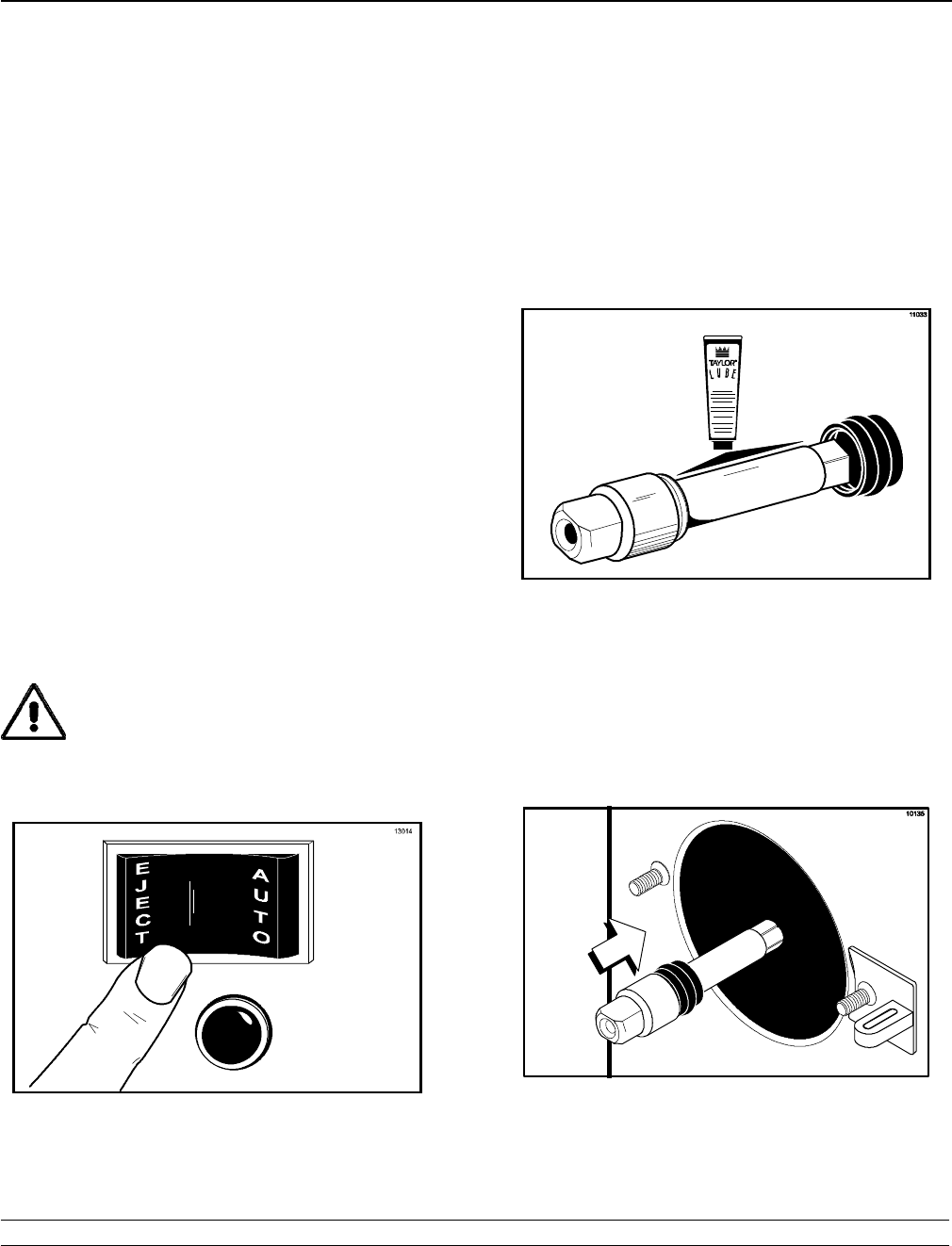

Step 2

Install the drive shaft. Lubricate the groove and shaft

portion that comes in contact with the bearing on the

beater drive shaft. Slide the seal over the shaft and

groove until it snaps into place. DO NOT lubricate the

hex end of the drive shaft. Partially fill the inside portion

of the seal with additional lubricant. Lubricate the flat

side of the s eal that comes in contact with the bearing.

Figure 6

Insert the drive shaft through the rear s hell bearing and

engage the hex end firmly into the gear box coupling.

Be certain that the drive shaft fits into the coupling

without binding.

Figure 7