10

Important: To the Operator Model 430 Torque

Section 5 Important: To the Operator

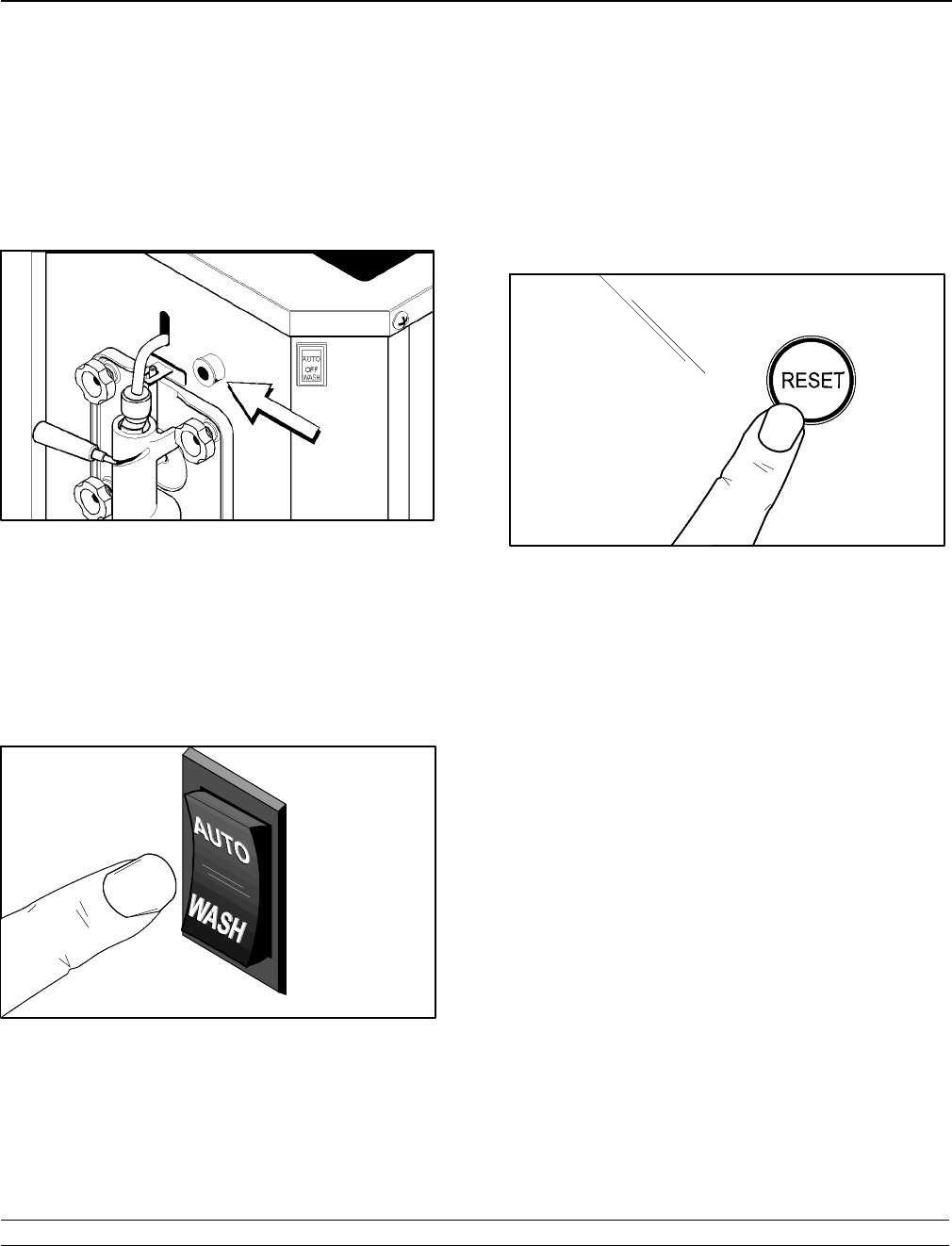

Viscosity Adjustment

The viscosity (thickness) of the slush can be adjusted

by turning the viscosity adjustment screw on the upper

right side of the front panel. T urn the viscosity

adjustment screw clockwise for a thicker product, or

counterclockwise for a thinner product. After making

an adjustment, allow the refrigeration system to cycle

2 or 3 times to accurately evaluate the viscosity.

Figure 1

Power Switch

The center position is “OFF”. The “up” position is

“AUTO”, which activates the beater motor and the

refrigeration system. The “down” position is “WASH”,

which activates the beater motor only.

Figure 2

Reset Button

The reset button is located in the rear panel. The reset

protects the beater motor from an overload condition.

If an overload occurs, the reset mechanism will trip. To

properly reset the freezer, place the power switch in

the “OFF” position. Press the reset button firmly. Place

the power switch in the “W ASH” position and observe

the freezer’s performance. Once satisfied, place the

control switch in the “AUTO” position.

Figure 3

IMPORTANT: Do not use metal objects to press the

reset button.

Indicator Light - “Mix Low”

A mix level indicating light is located on the front of the

machine. When the light isflashing, it indicates that the

mix hopper has a low supply of product and should be

refilled as soon as possible.

Indicator Light - “Mix Out”

A mix out indicating light is located on the front of the

machine. When the light isflashing, it indicates that the

hopper is empty and the mix supply needs

replenishing. To prevent damage to the unit,

refrigeration discontinues automatically when the mix

out indicator lights.