UV-SVN03D-EN 21

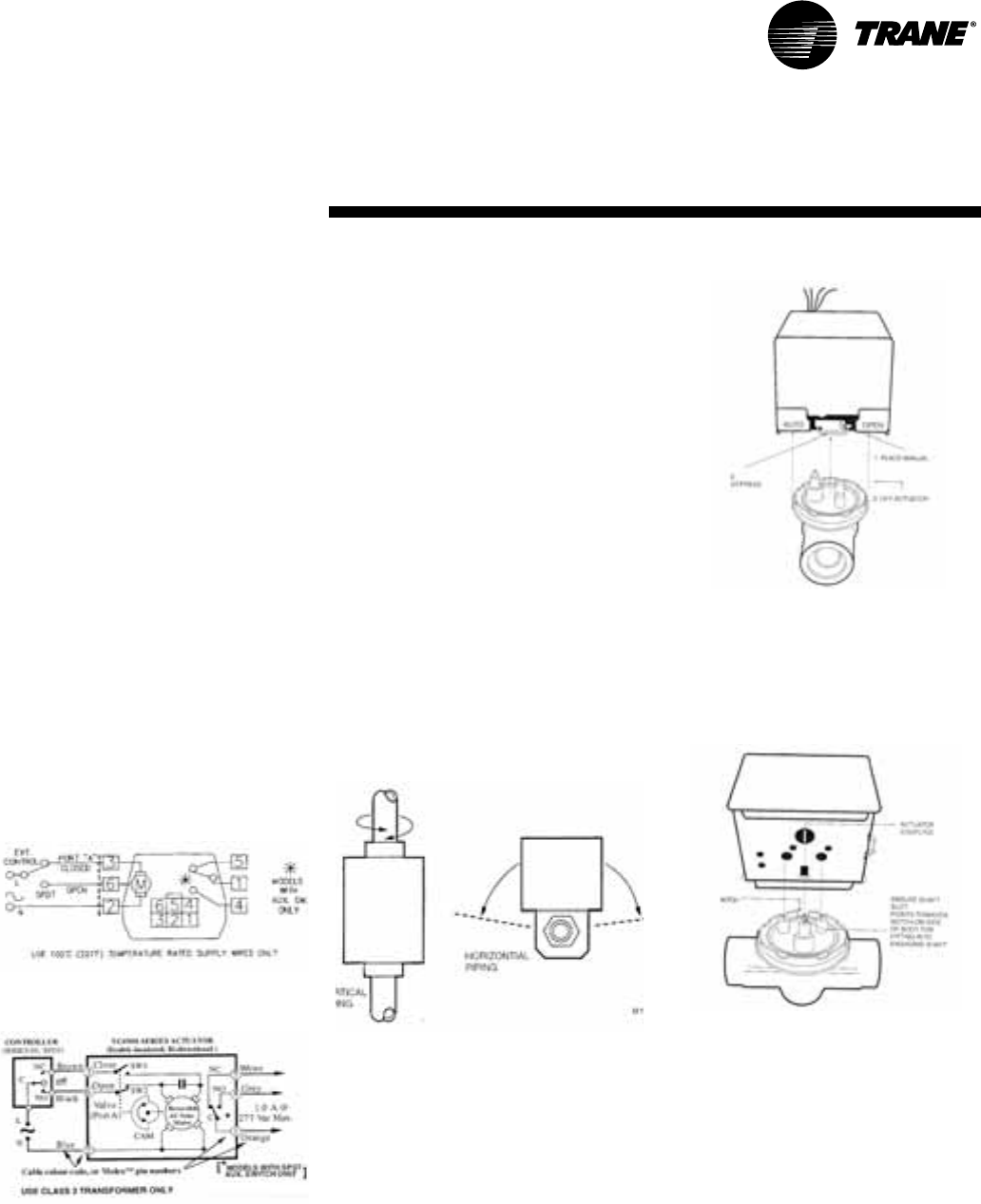

Manually Opening Valve

The manual opener can be manipulat-

ed only when in the up position. The A

port can be manually opened by firmly

pushing the white manual lever down

to the midway position and pushing

the lever in. In this position, both A

and B ports are open. This “manual

open” position may be used for filling,

venting and draining the system or

opening the valve during power fail

-

ure.

The valve can be closed by depressing

the white lever lightly and then pulling

the lever outward. The valve and actu-

ator will return to the automatic posi-

tion when power is restored.

Note: If the valve is powered open, it

cannot be manually closed, unless the

actuator is removed.

Wiring

A controller and a separate transform-

er is required to operate each valve.

See Figures 9 and 10. Port A “open”

and “closed” denote valve open and

closed positions.

Figure 9: Wiring for modulating valve

actuator

Figure 10: Wiring for modulating valve

actuator

The typical floating controller is an

SPDT controller with a center-off posi

-

tion. On a change in temperature from

the set point, the controller will close

the normally open (NO) or normally

closed (NC) contacts, driving the valve

to an intermediate position until a fur

-

ther change at the controller.

The valve is set between the limits of

the controller to satisfy various load

requirements. In the event of power

failure, the valve will stay in the posi

-

tion it was in before loss of power.

When power is restored, the valve will

again respond to controller demand.

Isolation Valves

Installation

The valve can be mounted in any posi-

tion on a vertical line. If the valve is

mounted horizontally, the actuator

must be even with or above the center

line. Make sure there is enough room

to remove actuator cover for servicing.

Mount the valve on the tube or pipe.

Note: Ensure the flow through the

valve is in the direction indicated by

the arrow stamped on the valve body.

Figure 11: Proper mounting for

isolation valves.

Servicing/Removal of Valves

The actuator can be removed from the

valve body. Removing the actuator is

recommended if soldering is being

conducted near the valve. To remove

the actuator:

1 Place the manual operating lever

to the Open position, Figure 12

2 Depress the locking button and lift

actuator until it separates from the

valve body.

Figure 12: Removing valve actuator

To install the actuator to the valve

body:

3 Align the slot on the shaft of the

valve with the valve body notch on

side of body. See Figure 13.

Figure 13: Installing isolation valve

4 Install body valve into pipe.

5 Wiring connections may be made

either before or after actuator in-

stalled on body.

6 Place the manual operating lever

on the actuator in the OPEN posi-

tion.

7 Align actuator coupling to slot on

the shaft of the valve body and fit

the head onto the valve body to

ensure the shaft seats correctly,

Figure 11.

8 Press the actuator and valve body

until it secures together.

Installation