INSTALLATION MANUAL • MN-29805 • 21.

INSTALLATION

CT EXPRESS™ CHECKLIST

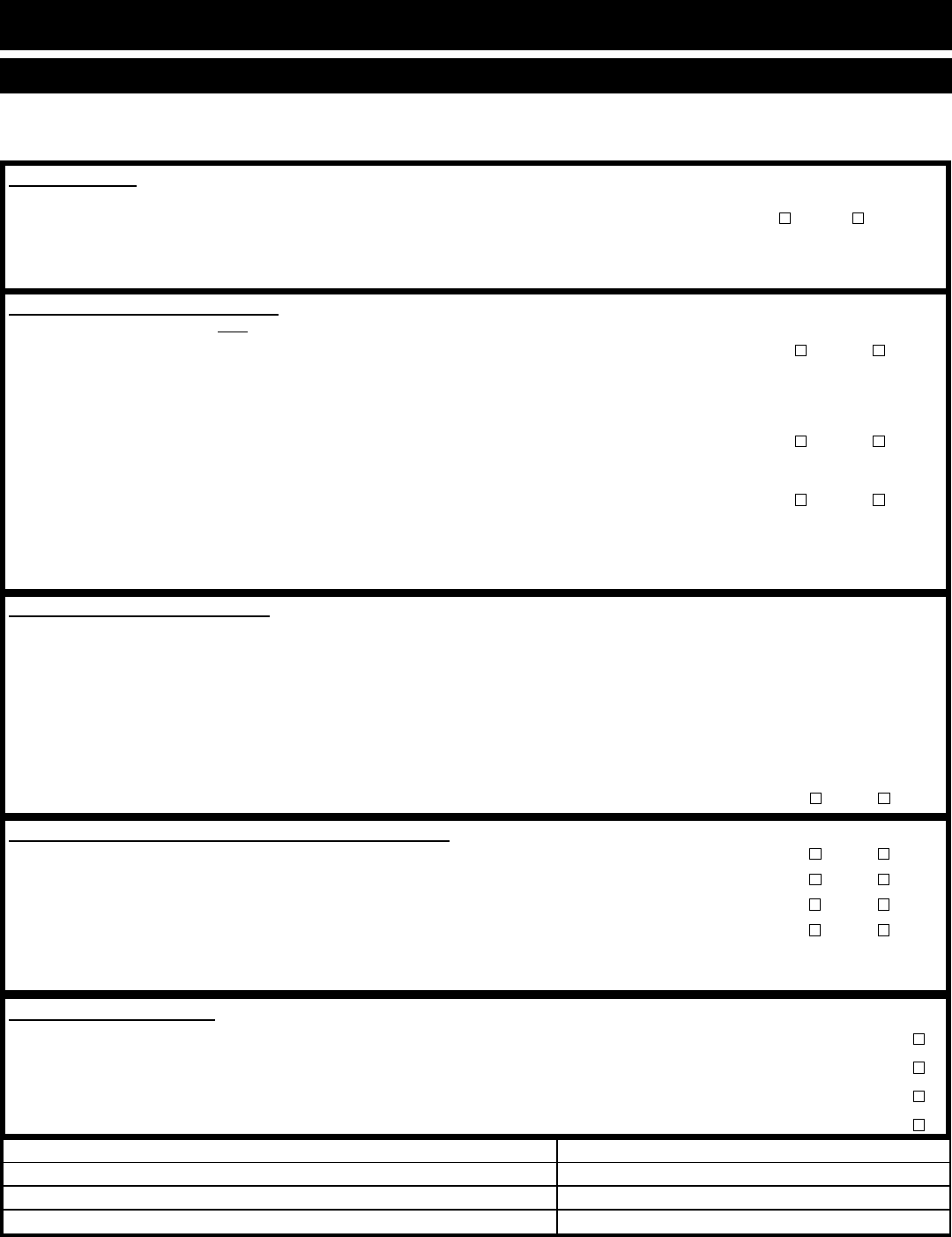

Use this list as a nal check of oven installation conformance.

Damage directly attributed to improper set up, installation, or cleaning can invalidate warranty claims.

CLEARANCES:

Left: 4" (152mm) — Service access of 18" (457mm) recommended.

8" (203mm) from heat or steam producing equipment.

Right: 4" (102mm)

Back: 4" (102mm) for plumbing

Top: 20" (508mm) air movement Bottom: 4" (102mm) air movement

ARE ALL CLEARANCE

REQUIREMENTS MET?

YES NO

IF NO, EXPLAIN: ________________________

________________________________________

WATER SUPPLY AND DRAINS:

Verify hook-up to ONE (1) cold water supply line with a 3/4" (19mm) G

water connection supply line. Verify inlet water pressure is at a minimum

of 30 PSI (2.8 bar). Maximum water pressure is not to exceed 90 PSI

(6 bar). Verify drain diameter of 1-1/2" (38mm) with a positive descending

slope, and with a 2" (51mm) air gap which is free of obstructions before

connection to the site drain. Verify 1/8" (3.2mm) pitch to 10' (305cm) of

drain line. Materials must withstand temperatures up to 200°F (93°C).

IMPORTANT: Alto-Shaam has listed Water Quality Requirements in the

installation manual for this equipment. It is the responsibility of the end

user to have the water connected to this appliance tested to ensure these

standards are met before putting the oven into use. Failure to meet these

standards will void the warranty if damage to the oven is found to be

related to water quality.

ARE BOTH WATER SUPPLY LINES

PROPERLY CONNECTED?

YES NO

IF NO, EXPLAIN: ___________________________

IS A FILTER SYSTEM INSTALLED

ON THIS UNIT?

YES NO

STORE HAS SEEN THIS

RECOMMENDATION:

YES NO

SIGNATURE OF STORE REPRESENTATIVE:

___________________________________________

CONTROL BOARD CONNECTIONS & OPERATION:

ExpressTouch: With the Power

on, press the Tool Box

key, then the Settings Key to access software version

in the upper left corner.

Simple Control: As unit is powered on, software

version will appear in the LED display.

ALL BOARD CONNECTIONS TIGHT: YES NO

ALL FUNCTIONS ARE DISPLAYED:

YES NO

ALL FUNCTIONS ON CONTROL OPERATE:

YES NO

UNIT OPERATES IN ALL MODES:

YES NO

IF NO, EXPLAIN: _________________________________________

PHYSICAL CONDITION: *reference installation instructions for complete information 4

Bottom of oven has been checked for damage due to improper positioning on site ...................................................

Verify all gaskets and hoses are in place and function properly ..................................................................................

Verify the installation of drip pans*, racks, shelves, drain screen, spray hose* ..........................................................

Verify the oven is level and installed on a solid, water resistant surface ....................................................................

ELECTRICAL CONNECTIONS:

Verify electrical power requirements for oven.

Verify voltage at terminal block.

Check all terminals for tightness.

LINE VOLTAGE AT TERMINAL BLOCK (tO gROuNd):

LINE 1: _________ LINE 2:_________ LINE 3: _________

LINE VOLTAGE (

phase to phase): LINE 1 to 2: __________

LINE 2 to 3: __________

LINE 3 to 1: __________

ELECTRICAL SUPPLY LINE SIZE: ______________

ALL ELECTRICAL TERMINALS TIGHT:

YES NO

VOLTAGE: ______________

PHASE: ______________

BREAKER SIZE: ______________

RB_____________

RECORD SOFTWARE VERSION: DB_____________

serviCe agenCy: start-up date:

installation name:

model no.: serial no.:

teCh signature: Customer signature: