CONTENTS

Page

SAFETY CONSIDERATIONS ...................1

INTRODUCTION ..............................2

General ......................................2

Job Data ....................................2

Equipment Required .........................2

INSTALLATION .............................2-30

Receiving the Machine .......................2

• INSPECT SHIPMENT

• IDENTIFY MACHINE

• PROVIDE MACHINE PROTECTION

Rigging the Machine .........................2

• RIG MACHINE ASSEMBLY

• RIG MACHINE COMPONENTS

• COMPONENT DISASSEMBLY

Install Machine Supports ....................14

• INSTALL STANDARD ISOLATION

• INSTALL OPTIONAL ISOLATION

• INSTALL SPRING ISOLATION

Connect Piping .............................17

• INSTALL WATER PIPING TO HEAT

EXCHANGERS

• INSTALL WATER TO OIL COOLER ON FA

COMPRESSORS

• INSTALL VENT PIPING TO RELIEF DEVICES

Make Electrical Connections .................20

• CONNECT CONTROL INPUTS

• CONNECT CONTROL OUTPUTS

• CARRIER COMFORT NETWORK INTERFACE

Install Field Insulation .......................28

• FACTORY INSULATION (OPTIONAL)

INSTALLATION START-UP REQUEST

CHECKLIST .............................CL-1

INTRODUCTION

General —

The 17/19EX machine is factory assembled,

wired, and leak tested. Installation consists primarily of es-

tablishing water and electrical services to the machine. The

rigging, installation, field wiring, field piping and insulation

are the responsibility of the contractor and/or customer. See

Fig. 1 for model number information.

Job Data

Necessary information consists of:

• job contract or specifications

• machine location prints

• rigging information

• piping prints and details

• field wiring drawings

• starter manufacturer’s installation details

• Carrier certified drawings

Equipment Required

• mechanic’s tools (refrigeration)

• volt-ohmmeter and clamp-on ammeter

• leak detector (halide or electronic)

• absolute pressure manometer or wet-bulb vacuum

indicator

• portable vacuum pumps

INSTALLATION

Receiving the Machine

INSPECT SHIPMENT

Do not open any valves or loosen any connections. The

standard 17/19EX machine may be shipped with a ni-

trogen holding charge or with the refrigerant charge iso-

lated within the utility vessel.

1. Inspect for shipping damage while machine is still on ship-

ping conveyance. If machine appears to be damaged or

has been torn loose from its anchorage, have it examined

by transportation inspectors before removal. Forward claim

papers directly to transportation company. Manufacturer

is not responsible for any damage incurred in transit.

2. Check all items against shipping list. Immediately notify

the nearest Carrier representative if any item is missing.

3. To prevent loss or damage, leave all parts in original pack-

ages until beginning installation. All openings are closed

with covers or plugs to prevent dirt and debris from en-

tering the machine’s components during shipping. A full

operating oil charge is placed in the oil sump of the com-

pressor before shipment.

IDENTIFY MACHINE — The machine model number,

serial number, and heat exchanger sizes are stamped on

machine identification nameplate (Fig. 1). Check this infor-

mation against shipping papers and job data.

PROVIDE MACHINE PROTECTION — Protect machine

and starter from construction dirt and moisture. Keep pro-

tective shipping covers in place until machine is ready for

installation.

If machine is exposed to freezing temperatures after water

circuits have been installed, open waterbox drains and re-

move all water from cooler and condenser. Leave drains open

until system is filled.

Rigging the Machine — The 17/19EX machine can

be rigged as an entire assembly. It also has flanged connec-

tions that allow the compressor, utility vessel, cooler, and

condenser sections to be separated for ease of installation.

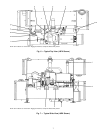

Figures 2 and 3 show 17/19EX components.

RIG MACHINE ASSEMBLY — See rigging instructions on

label attached to machine. Also refer to the rigging infor-

mation found in Fig. 4-9 and Tables 1-12. Lift machine only

from the 4 points indicated in rigging guide.Each lifting cable

or chain must be capable of supporting the entire weight of

the machine.

Lifting machine from points other than those specified

may result in serious damage to the unit and personal

injury. Rigging equipment and procedures must be ad-

equate for machine weight. See Table 1 for machine

weights.

NOTE: These weights are broken down into compo-

nent sections for use when installing the unit in

sections. For the complete machine weight, add all com-

ponent sections and refrigerant charge together. Total

machine weight is also stenciled on the cooler and con-

denser sections.

2