◊ The gas valve is energized allowing gas and air into the burner chamber to

be ignited by the hot surface igniter.

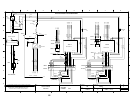

◊ The Hot Air Burner Control Module (N20) senses at least 1.5 micro amps

DC from the flame sensor (P1) at terminal 3 of connector X2 and sends a

signal from terminal 2 of connector X1 to terminal 12 of connector X15

on the Control Board (A10)

• The heat circuit will remain energized until the cabinet set temperature is

reached as sensed at probe B6.

e The steam circuit is energized.

• 120 VAC is sent from terminal 4 of connector X12 on the Control Board

(A10) to the coil of the Y3 solenoid allowing water to be thrown against the

element until the bypass probe (B5) senses 183 degrees F.

• The heat circuit will remain energized until the cabinet set temperature is

reached

f If the bypass probe (B5) drops below the set level the steam circuit will start again

g When the condensate box is heated to 140 degrees F at the B3probe, 120 VAC is

sent from terminal 5 of connector X12 to the condenser valve (Y1) until the

temperature drops.

h When the timer counts to 0 or the core temp probe (B10) reaches the set amount

the cycle ends and the steam generator reverts to the standby temperature of 190-

degree F.