10

Installation

Gas Downdraft Cooktop

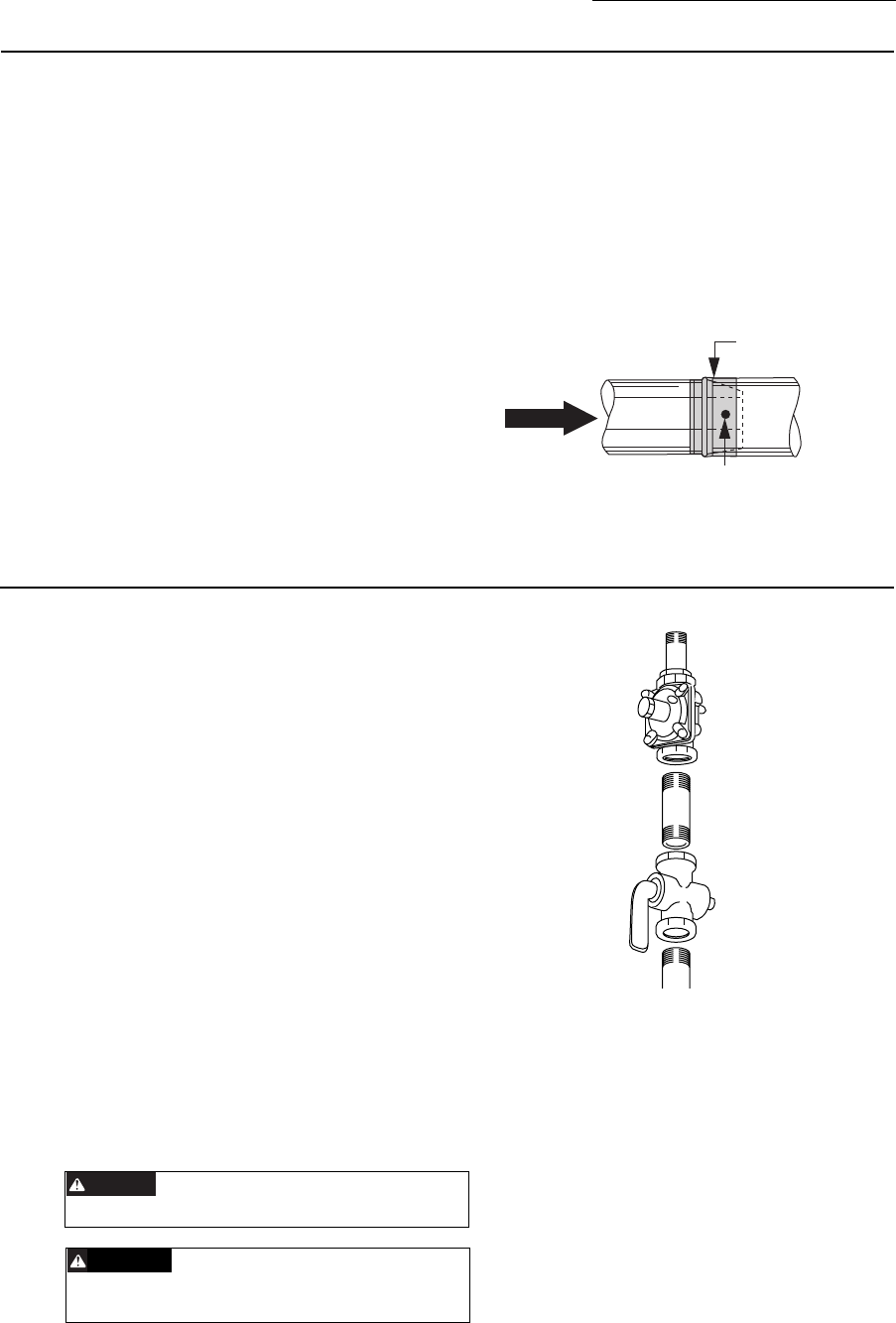

•Install the supplied pressure regulator and

nipple in the gas line as close to the cooktop

inlet as possible. Allowances for ventilation

ducting may be necessary.

–Make sure the regulator is installed in the

right direction.

•Install a manual shut-off valve in the gas line

in an easily accessible location.

Note: Instead of using solid piping to connect

to pressure regulator, an approved flexible

metal appliance connector may be used

between the pipe stub and the shut-off valve

and the pressure regulator, if local codes

permit.

– Appropriate flare nuts and adapters are

required at each end of the flexible

connector.

•Turn on the gas. Check for leaks using a

liquid leak detector at all joints in the system

(the pressure test nipple is adjacent to the

gas inlet pipe on the rear right hand side of

the cooktop bottom.

3

Install

Pressure

Regulator

Step

Regulator

Solid Piping

or Flexible

Connector

Shut-Off

Valve

Pipe Stub

Do not use a flame to check for

gas leaks.

IMPORTANT: Disconnect the cooktop and

the individual shut-off valve from the gas

supply piping system during any pressure

testing of that system at test pressures greater

than 1/2 psig. Isolate the cooktop from the

gas supply piping system by closing the

individual manual shut-off valve to the

cooktop during any pressure testing of the gas

supply piping system at test pressures equal to

or less than 1/2 psig.

CAUTION

IL NE FAUT PAS UTILISER

DE FLAMME POUR VÉRIFIER S’IL Y A

DES FUITES.

CAUTION

PRUDENCE

2

Install the

Ductwork

Step

• The downdraft blower system is designed for

use with 3-1/4" x 10" ductwork. It can be

transitioned to 6" round.

•Ductwork MUST be vented to the outside –

never into a crawl space, attic or other

enclosed space.

•6" PVC duct should be used when installing

under a concrete slab.

Note: Local building code must be followed

for installation and in specifying approved

type and schedule of PVC duct used.

• DO NOT USE flexible plastic ducting.

• Always use appropriate roof or wall cap with

damper. Laundry type wall caps should

never be used.

• Use the straightest duct run possible.

• For satisfactory performance the duct run

should not exceed 150 ft. or its equivalent

length when bends or various fittings are

used. Refer to the table of equivalent lengths

to calculate your installation.

• Install ductwork so the piece of duct nearest

the downdraft unit slots INTO the next

piece of the duct. Secure the joints with self-

tapping screws and apply duct tape around

the joints to ensure an airtight seal.

Air

Duct Tape

Over Seam and Screw

Screw