14

®

Model MSX Make-Up Air

for one minute, the system is ready to be charged or

refrigerant in another portion of the system can be

opened to the coil. A steady rise in microns would

indicate that moisture is still present and that the coil

should be further vacuumed until the moisture has

been removed.

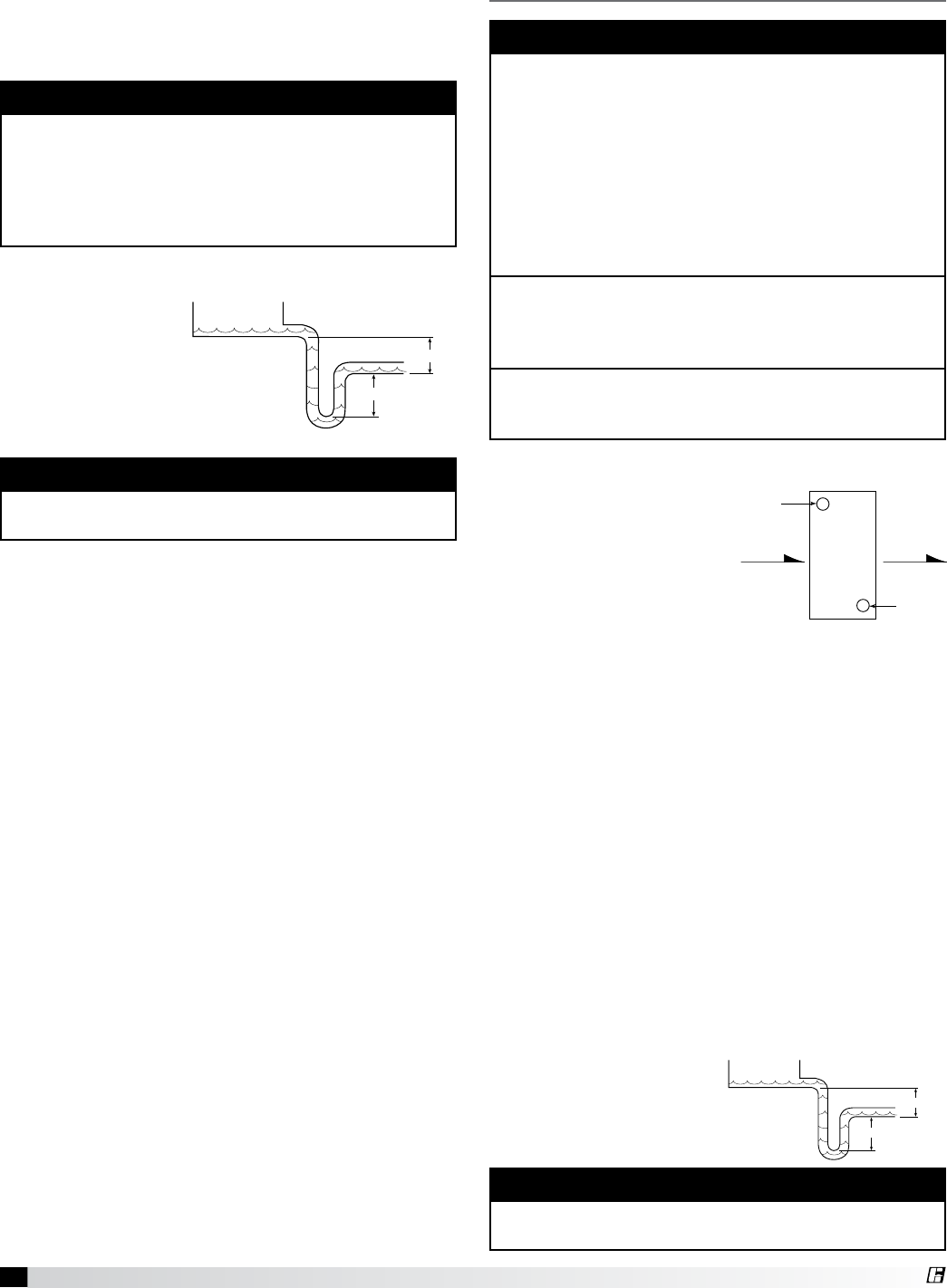

8. Install the Drain Line

Connect an

unobstructed drain

line to the drain

pan. A trap should

be used to prevent

sewer gas from being

drawn into the unit.

NOTE

Failure to obtain a high vacuum indicates a great

deal of moisture or a small leak. Break the vacuum

with a charge of dry nitrogen or other suitable

gas and recheck for leaks. If no leaks are found,

continue vacuuming the coil until the desired

vacuum is reached.

IMPORTANT

All traps must be installed below the roof line or be

otherwise protected from freezing.

6 in. min.

6 in. min.

Drain Trap

6 in. min.

6 in. min.

Drain

Trap

Installation of Chilled Water Coil

Piping (optional)

1. Verify Coil Hand Designation

Check the coil hand

designation to ensure that

it matches the system.

Coils are generally

plumbed with the supply

connection located on

the bottom of the leaving

air-side of the coil and the

return connection at the top of the entering air-side

of the coil. This arrangement provides a counter flow

heat exchanger and positive coil drainage.

2. Check the Coil for Leaks

Pressurize the coil to 100 psig with dry nitrogen or

other suitable gas. The coil should be left pressurized

for a minimum of 10 minutes. If the coil holds the

pressure, the hook-up can be considered leak free.

If the pressure drops by 5 psig or less, re-pressurize

the coil and wait another 10 minutes. If the pressure

drops again there is likely one or more small leaks

which should be located and repaired. Pressure losses

greater than 5 psig indicate a large leak that should be

isolated and repaired.

3. Connect the Supply and Return Lines

Connect the supply and return lines as shown above.

4. Install the Drain Line

Connect an unobstructed

drain line to the drain pan.

A trap should be installed

to prevent sewer gas from

being drawn into the unit.

Hot Return

Connection

Cold Supply

Connection

Entering Air Leaving Air

IMPORTANT

Guidelines for the installation of the cooling coil

have been provided to insure proper performance

of the coils and their longevity. These are general

guidelines that may have to be tailored to meet the

specific requirements of any one job. As always,

a qualified party or individual should perform the

installation and maintenance of the coil. Protective

equipment such as safety glasses, steel toe boots

and gloves are recommended during the installation

and maintenance of the coil.

When installing couplings, do not apply undue

stress to the connection. Use a backup pipe

wrench to avoid breaking the weld between the coil

connection and the header.

All field piping must be self-supporting. System

piping should be flexible enough to allow for the

thermal expansion and contraction of the coil.

IMPORTANT

All traps must be installed below the roof line or be

otherwise protected from freezing.