16

®

Model MSX Make-Up Air

Start-Up - Blower

1. Check the Voltage

Before starting the unit, compare the supplied voltage,

hertz, and phase with the unit and motor’s nameplate

information.

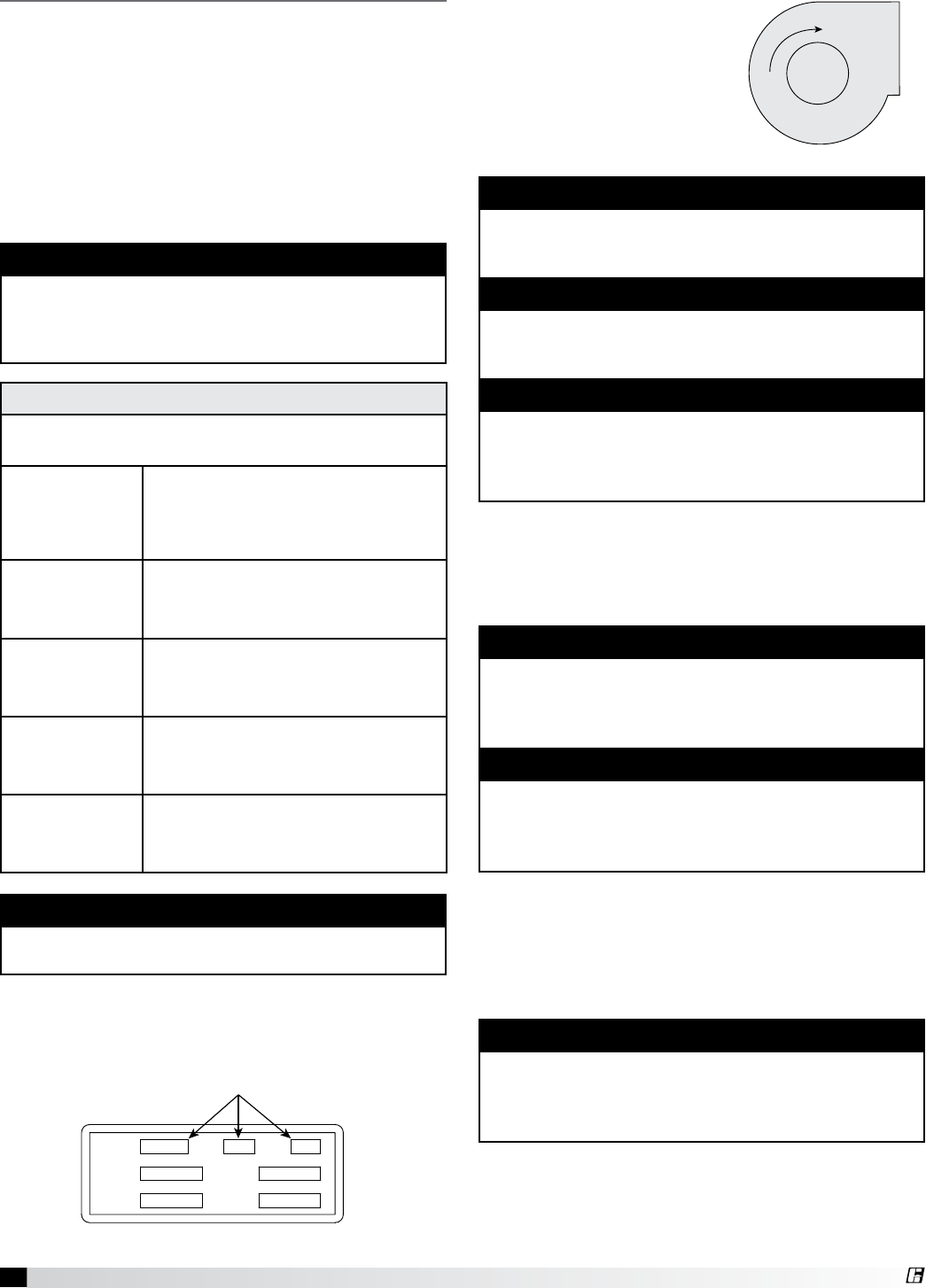

2. Check the Blower Rotation

Open the blower access door

and run the blower momentarily

to determine the rotation.

Arrows are placed on the

blower scroll to indicate the

proper direction or reference

the example shown to the right.

Refer to the Start-Up Checklist in the Reference

section before proceeding further!

Pre Start-Up Check

Rotate the fan wheel by hand and make sure no parts

are rubbing. Check the V-belt drive for proper alignment

and tension (a guide for proper belt tension and

alignment is provided in the Belt Maintenance section).

Check fasteners, set screws and locking collars on the

fan, bearings, drive, motor base, and accessories for

tightness.

SPECIAL EQUIPMENT REQUIRED

Required and recommended tools. Equivalent

products may be used.

Voltage &

Amperage

Meter

Manufacturer: Fluke

Model: 177

Phone: 1-800-44-FLUKE

www.fluke.com

Thermometer

Manufacturer: Fluke

Model: 50

Phone: 1-800-44-FLUKE

www.fluke.com

Micro Amp

Meter

Manufacturer: Fluke

Model: 116

Phone: 1-800-44-FLUKE

www.fluke.com

U-Tube

Manometer

Manufacturer: Dwyer

Model: Slack Tube

Phone: 1-219-897-8000

www.dwyer-inst.com

Tachometer

Manufacturer: Monarch

Model: Pocket Tach 100

Phone: 1-800-999-3390

www.monarchinstrument.com

WARNING

Check the housing, blower, and ductwork for any

foreign objects before running the blower.

NOTE

To reverse the rotation on three phase units,

disconnect and lock-out the power, then

interchange any two power leads.

NOTE

To reverse the rotation on single phase units,

disconnect and lock-out the power, then rewire the

motor per the manufacturer’s instructions.

IMPORTANT

If the blower is rotating in the wrong direction, the

unit will move some air, but will not perform as

designed. Be sure to perform a visual inspection to

guarantee the correct blower rotation.

WARNING

Disconnect and lock-out all power and gas before

performing any maintenance or service to the unit.

Failure to due so could result in serious injury or

death and damage to equipment.

3. Check for Vibration

Check for unusual noise, vibration or overheating of

the bearings. Reference the Troubleshooting section

for corrective actions.

4. Motor Check

Measure the motor’s voltage, amps and RPM.

Compare to the specifications. Motor amps can be

reduced by lowering the motor RPM or increasing

system static pressure.

IMPORTANT

Excessive vibration may be experienced during

the initial start-up. Left unchecked, it can cause a

multitude of problems including structural and/or

component failure.

IMPORTANT

Generally, fan vibration and noise is transmitted

to other parts of the building by the ductwork. To

minimize this undesirable effect, the use of heavy

canvas duct connectors is recommended.

IMPORTANT

Additional starters and overloads may be provided

in the make-up air control center for optional

exhaust blowers. Any additional overloads must be

checked for proper voltage, amps and RPMs.

Electrical Nameplate

SUP HP

MCA

EXH HP

MOP

VOLTS HZ PH

Unit’s Total MCA

Voltage, Hertz, Phase

SUP HP

MCA

EXH HP

MOP

VOLTS HZ PH

Voltage, Hertz, Phase

Blower Rotation

Blower

Housing

R

o

t

a

t

i

o

n