Model PFE- 590/592

3-1. OPERATING COMPONENTS

(Continued)

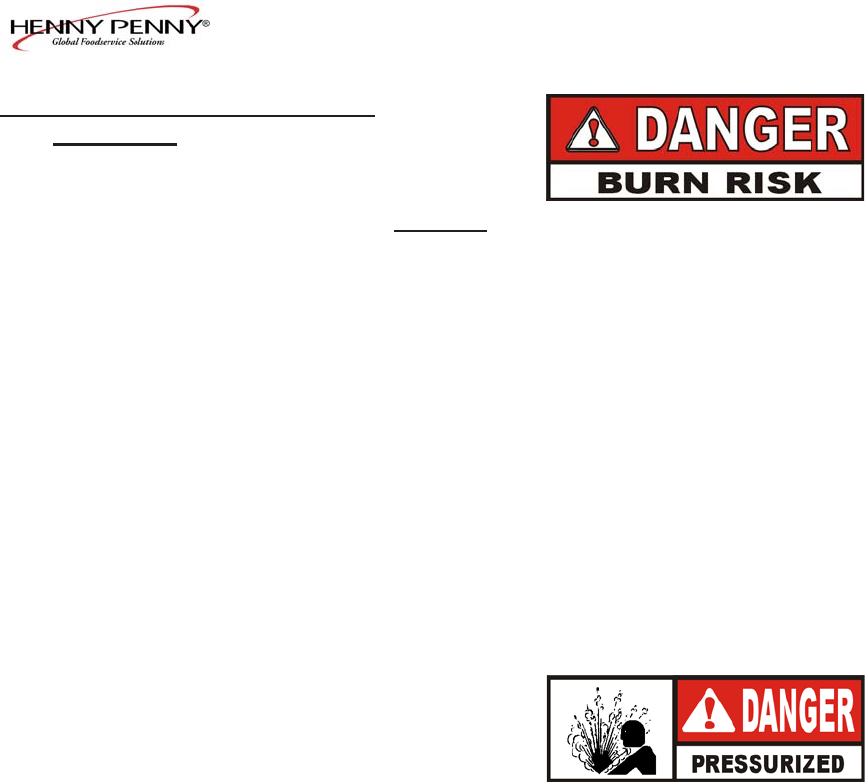

Safety Relief Valve Ring

DO NOT PULL THIS RING. SEVERE BURNS FROM

THE STEAM WILL RESULT.

Pressure Gauge Indicates the pressure inside the frypot.

Solenoid Valve An electromechanical device that causes pressure to be held in the

frypot

The solenoid valve closes at the beginning of the Cook Cycle and

opens automatically at the end of the Cook Cycle; if this valve

becomes dirty or the teflon seat nicked, pressure will not build and

it must be repaired per the Maintenance Section of the Technical

Manual

Drain Valve A two-way ball valve, normally in the closed position; turn the han-

dle to drain the shortening from the frypot into the filter drain pan

DO NOT OPEN THE DRAIN VALVE WHILE

FRYPOT IS UNDER PRESSURE. HOT SHORTEN-

ING WILL EXHAUST, AND SEVERE BURNS WILL

RESULT.

Drain Interlock Switch A microswitch that provides protection for the frypot in the event an

operator inadvertently drains the shortening from the frypot while

the main switch is in the COOK position; the switch is designed to

automatically shut off the heat when the drain valve is opened

Condensation Drain Pan The collection point for the condensation formed within the steam

exhaust system; it must be removed and emptied periodically,

usually daily

Shortening Mixing System The unit is equipped with a shortening mixing capability to ensure

the shortening is properly mixed to prevent an accumulation of

moisture, causing boiling action in the frypot; the filter pump is

activated by the controls, at preset intervals, to mix the shortening

Lid Latch The fryer lid is equipped with a mechanical catch on the front

of the lid which engages a bracket on the front of the frypot; this

device holds the lid down while the lid is being locked into

place, but is not meant to hold pressure in the frypot

703 3-2