C. Thermostat Bulb Positioning

BEFORE REPLACING, TEST THERMOSTATS:

These operational problems can easily be

corrected by thermostat bulb positioning.

Keating’s patented thermostat application is

accurate within 2°F of the dial setting between

250°F – 350°F. This accuracy is attained only if the

thermostat bulb is placed properly against the heat

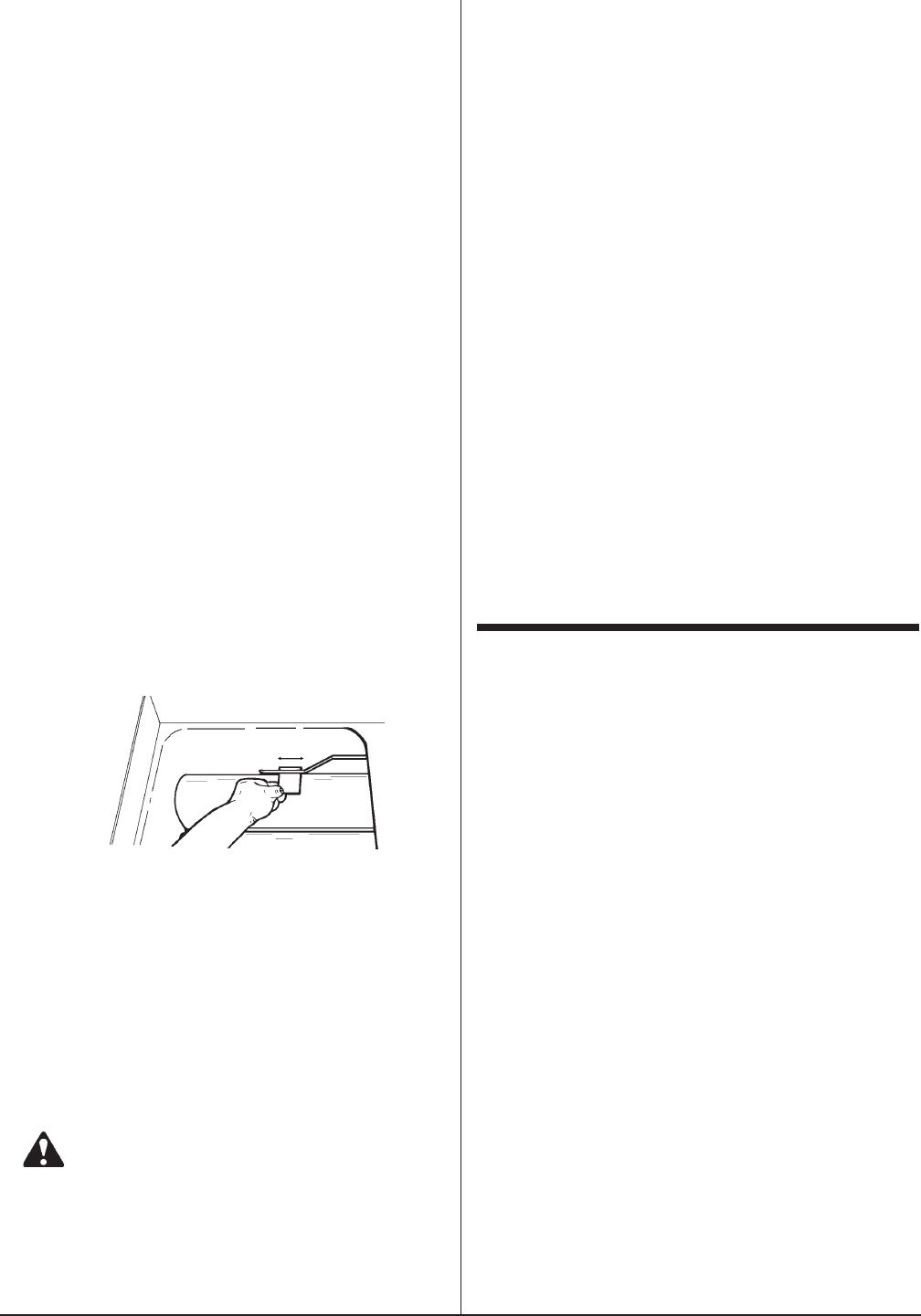

transfer tube. To quickly and accurately test for

proper bulb placement, a single thickness of writing

paper should be pulled through between the tube

and the bulb with medium resistance.*

1. *For gas fryers 14":

The end of thermostat bulb should touch the burner

tube.

2. For gas fryers 10x11, 18 & up:

If the bulb is too loose, the paper will slip through

with little or no resistance. A fryer with a thermostat

bulb that is too loose will overshoot.

Overshoot: The thermostat takes a long time to

cycle and then misses its preset temperature by

20°F - 40°F yielding a poor quality product.

If the bulb is too tight, the paper will either not pull

through or it will tear. A fryer with a thermostat bulb

that is too tight will short cycle.

Short Cycle: The thermostat will cycle rapidly while

the fryer is in the idle mode; the temperature will be

erratic.

Thermostat Bulb Positioning 10x11, 18 & up Fryer Gas

REQUIRED TEST EQUIPMENT:

Multimeter (for testing continuity)

CHECKING CONTINUITY WITH THE MULTIMETER

1. Rotate the thermostat shaft until an audible click

is heard.

2. Rotate the thermostat shaft left and right ten times

causing the switch to click on and off ten times,

while using the Multimeter to verify continuity.

3. If the switch does not show continuity during all

ten trials, replace the thermostat.

WARNING: Disassembling the thermostat

will void the thermostat warranty.

1. Set compression ring onto capillary end of bulb

finger tight, 1/2” from end of capillary.

2. Insert new thermostat bulb through control panel

back.

3. Apply oil resistant flexible sealant onto

compression fitting thread before installing fitting

into fryer vessel.

4. Position bent portion of bulb against far right heat

transfer tube and install compression fitting snugly

into fryer vessel.

5. Adjust bulb so at least 2” of bent portion of it is

next to heat transfer tube and tighten

compression nut onto compression fitting for fryer

10x11, 18 & up. The end of thermostat bulb

should touch the burner tube for 14" fryers.

6. Refill fryer with oil to “fill level line”.

7. Start fryer, preheat and calibrate with

thermometer.

D. Hi-Limit Check

The manual Hi-Limit test button can be used to test the

Hi-Limit Control by pushing and holding the button in

until the fryer reaches the Hi-Limit temperature

(425°F). Place an accurate thermometer in the oil. If

the Hi-Limit Control doesn’t shut off the fryer between

425°F and 450°F, have it replaced.

V SERVICE DIAGNOSIS

A properly adjusted Keating Instant Recovery® Fryer,

with no load, will cycle “On” approximately every 2-1/2

to 3 minutes. Each cycle will last 15 to 25 seconds,

ensuring that the temperature setting is held within a

narrow band.

The burners when on will produce clear blue flames

directed at the inside walls of the heat transfer tubes.

The radiant’s fins, located towards the rear of each

transfer tube, will glow bright red, helping to ensure

optimum heat distribution into the fryer vessel. All

radiants should be pulled gently forward until their

retaining clips engage the rear of the tubes.

On constant pilot models, the pilot light will be

between 3/8” to 1/2” high and will use about 180

BTU’s of gas per hour.

The runner pilot tube is used to ignite the burners.

Flames from the tube should be clear blue and

between 3/8” to 1/2” high spread across the entire

tube. The burners will ignite almost instantly after the

thermostat calls for heat.

Every Keating Instant Recovery® Gas Fryer has a

number of safety controls to ensure safe operation

and guard against component failure. Operation of

each control is explained in Section VI – Service.

11