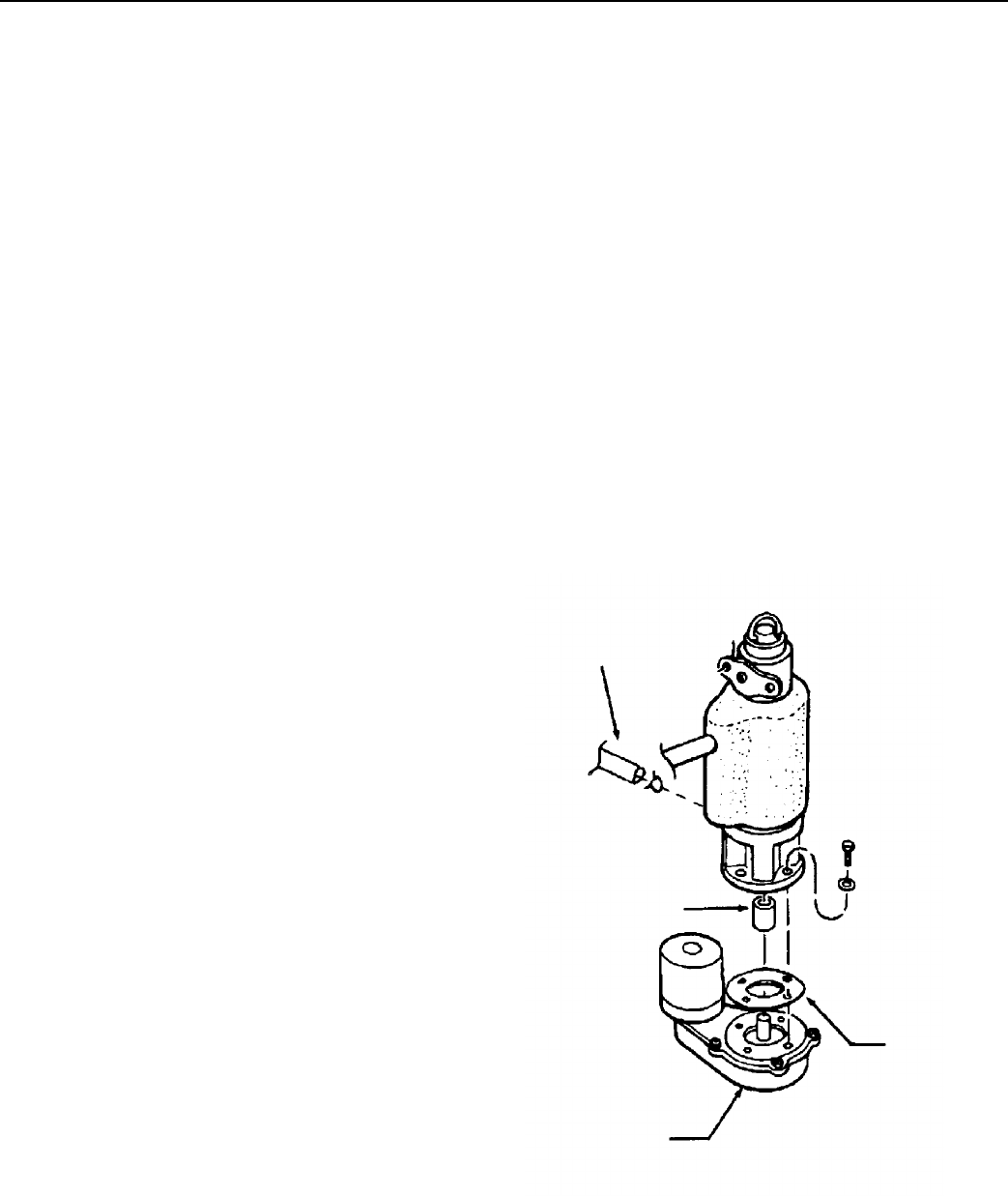

Water Seal & Bottom Bearing Replacement:

1. Remove old rotating half from the auger. Clean

the mounting area.

2. Place a bead of food grade sealant (such as

Scotsman part number 19-0529-01) onto the

shoulder of the auger where the rotating half of the

water seal will be installed.

3. Wash the new seal in water. While wet, slip it

onto the bottom of the auger, rubber side toward

the auger. Push up until seated against the

sealant. Do not allow any sealant to come into

contact with the face of the seal.

4. Wash the stationary half the water seal with

water. Slip it up into the bottom of the evaporator

until the bottom of the seal is inside the evaporator

about 1/4".

5. Push the bottom bearing against the water seal

until the bottom bearing is inside the evaporator

about 1/16".

6. Replace the evaporator on the adapter, and

re-attach the stand using the original bolts.

7. Attach the auger to the top bearing and breaker.

8. Return the auger to the evaporator and slide it

down until the splines touch the coupling.

9. Rotate the auger until the coupling splines align

with the auger.

10. Push the auger down, and rotate the breaker

until the screw holes line up with the pilot holes in

the evaporator.

11. When the auger is completely seated, reinstall

the breaker screws.

12. Replace permagum and foam top.

13. Switch on the water supply.

14. Check bin cover for electrical grounds and

switch on the electrical power.

15. Observe operation. The unit should make

minimal noise while producing ice. Catch first 2

minutes of ice and discard it.

16. Replace the bin cover and all panels.

Evaporator

Follow all steps to remove the auger & bearings.

1. Recover the refrigerant charge. Note: The

refrigeration system must not remain open for

more than 15 minutes.

2. Unsweat suction and cap tube connections.

3. Remove evaporator from the machine.

4. Remove old drier.

5. Install new evaporator.

6. Install new HFC type drier.

Note: The refrigeration system uses an HFC type

refrigerant and MUST use an HFC type drier.

7. Braze the drier connections, cap tube and

suction line together.

8. Evacuate to 200 microns, and weigh in the

system charge.

Water Line

Coupling

Gear

Reducer

Gasket

AFE325

August 1994

Page 19