Refrigeration System

This ice machine uses R-134a as the refrigerant.

This refrigerant has no chlorine, and therefore

requires polyolester type refrigerant oil. This oil

requires specific service procedures.

Service Recommendations:

This ice machine has a sealed refrigeration

system. It must not be tapped into unless

absolutely necessary. If access is required, tap into

the "process" tubes (dead-end tubing that has

been pinched-off and brazed shut).

After recovery, repair, evacuation and re-charging,

remove the piercing valves:

1. Pinch off the process tube below the valve.

2. Remove the valve.

3. Braze the end of the tube shut.

A HFC type liquid line drier is required. "Standard"

driers may not take out enough moisture and may

affect the oil additives.

The time that the refrigeration system is open to

the air must not exceed 15 minutes. The oil will

rapidly absorb moisture from the air, and the

contact time must be kept to a minimum.

A special or very sensitive electronic leak detector

will be needed to locate refrigerant leaks. Many

are on the market that will sense R-134a.

Recovery and vacuum equipment should use

polyolester oil to minimize cross-contamination.

A HFC type drier must be used.

As with any other refrigerant, do not place

pressurized air or oxygen into the refrigeration

system.

Evacuation to 200 microns is recommended.

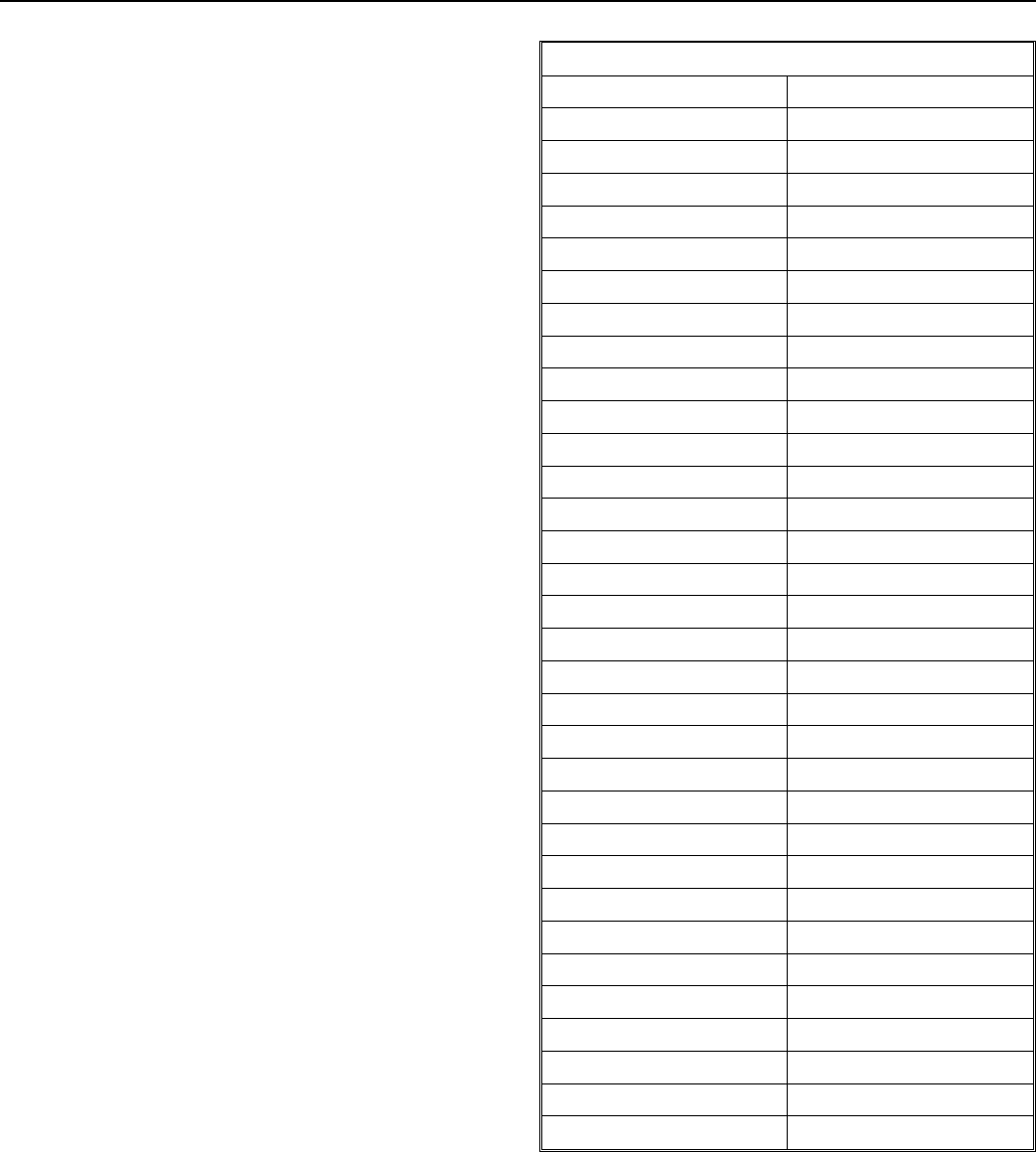

Temperature Pressure Chart, Selected Points

Temperature in

0

F. PSIG of R-134a

-10 2.0

-6 3.7

-4 4.6

-2 5.5

0 6.5

1 7.0

2 7.5

3 8.0

4 8.6

5 9.1

10 12.0

12 13.2

14 14.4

16 15.7

18 17.1

20 18.4

25 22.1

30 26.1

31 26.9

32 27.8

33 28.6

34 29.5

35 30.4

40 35.0

45 40.0

50 45.4

75 78.7

90 104.3

110 146.4

120 171.1

130 198.7

150 262.8

AFE325

August 1994

Page 20